Ultrahigh-strength steel sheet superior in hydrogen-embrittlement resistance

An ultra-high-strength, thin-steel technology, applied in temperature control, etc., can solve problems such as poor mechanical production efficiency, and achieve the effect of improving hydrogen embrittlement resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

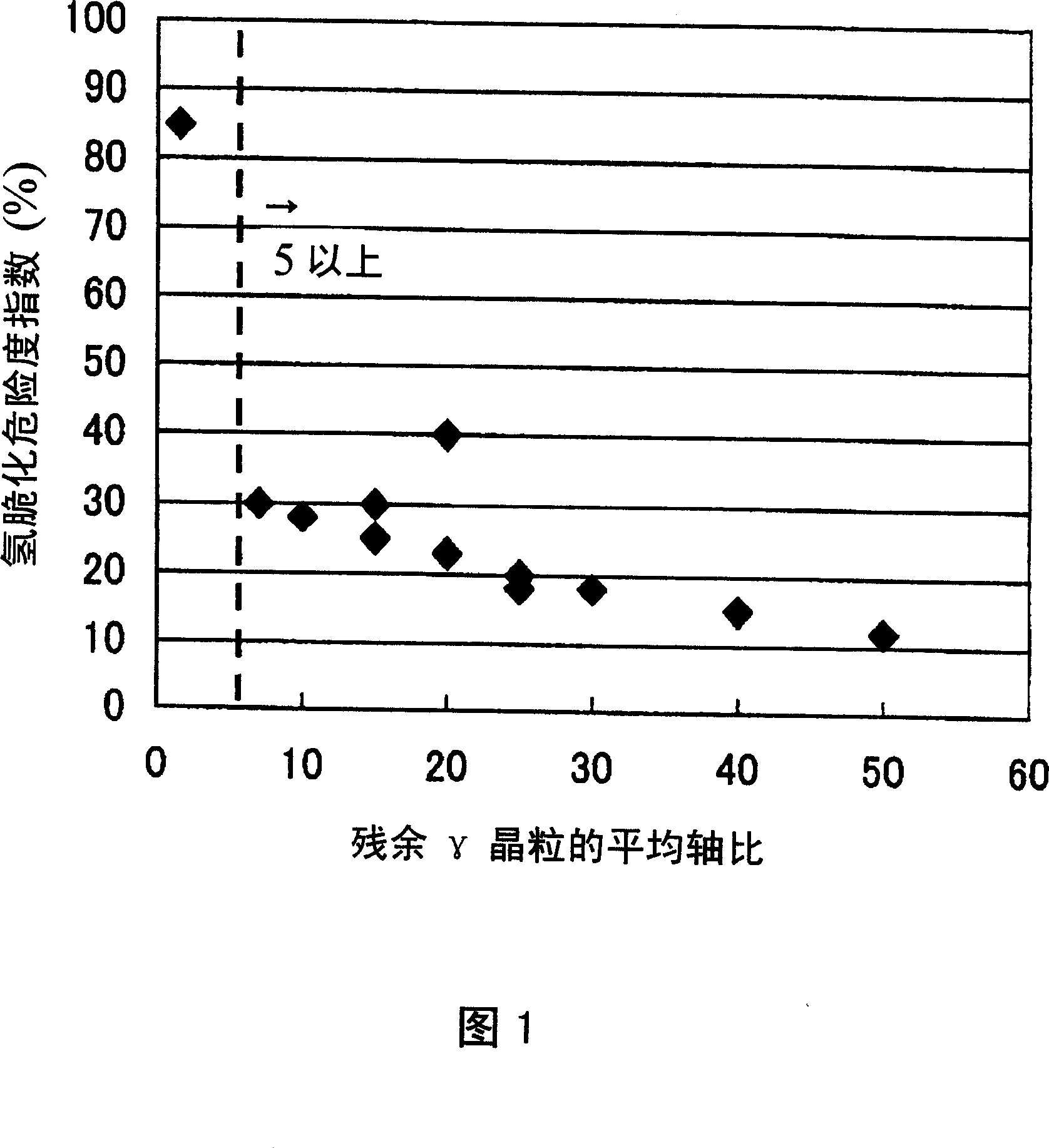

[0057] The ultrahigh-strength thin steel sheet according to Embodiment 1 of the present invention is characterized by containing C: 0.10 to 0.25%, Si: 1.0 to 3.0%, Mn: 1.0 to 3.5%, and P: 0.15% or less in mass percent , S: 0.02% or less, Al: 1.5% or less (excluding 0%), and also contains iron and unavoidable impurities as the rest, and contains more than 1% of residual austenite in terms of the area ratio of the entire structure. Bainitic ferrite and martensite totaling more than 80%, and ferrite and pearlite totaling less than 9% (including 0%). Wherein the average axial ratio (major axis / short axis) of the retained austenite grains is 5 or more, and the tensile strength is 1180 MPa or more. The reason for specifying these conditions, the measurement method, etc. are explained below.

[0058]

[0059] Retained austenite is not only useful for improving the total elongation, but also greatly contributes to the improvement of hydrogen embrittlement resistance, so it is made ...

Embodiment approach 2

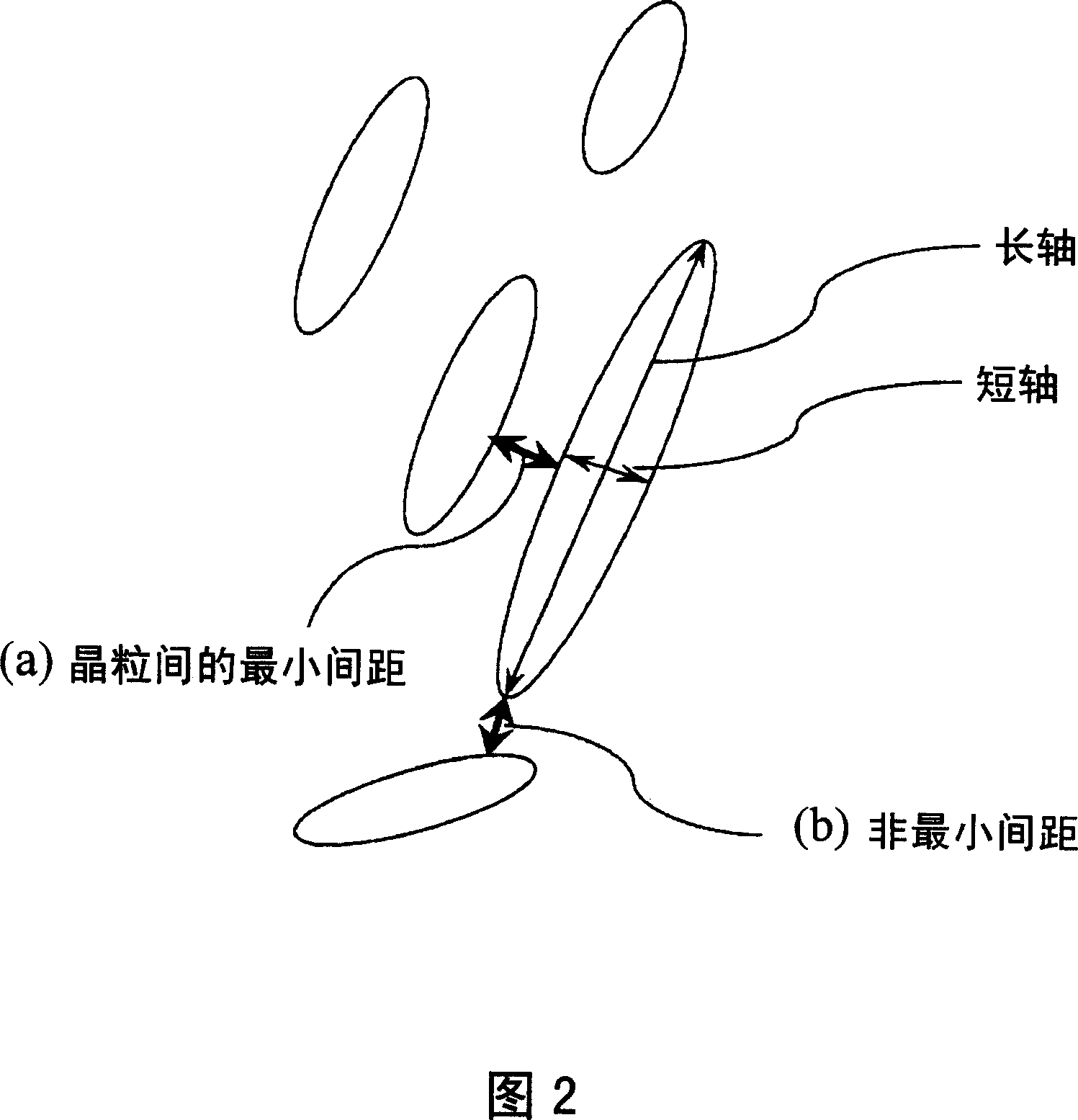

[0130] The ultrahigh-strength steel sheet according to Embodiment 2 of the present invention is characterized by containing C: 0.10 to 0.25%, Si: 1.0 to 3.0%, Mn: 1.0 to 3.5%, and P: 0.15% or less in mass percent , S: 0.02% or less, Al: 1.5% or less (excluding 0%), and the rest are composed of iron and unavoidable impurities, which contain more than 1% of retained austenite in terms of the area ratio of the entire structure, totaling More than 80% of bainitic ferrite and martensite, and a total of less than 9% (including 0%) of ferrite and pearlite, and the average minor axis length of the retained austenite grains is 1 μm or less, and the closest adjacent distance between the retained austenite grains is 1 μm or less, the average axis ratio (major axis / short axis) of the retained austenite grains is 5 or more, and the tensile strength is 1180 MPa or more . Here, a total of 80% or more of bainitic ferrite and martensite, and / or a total of 9% or less (including 0%) of ferrite ...

Embodiment 1

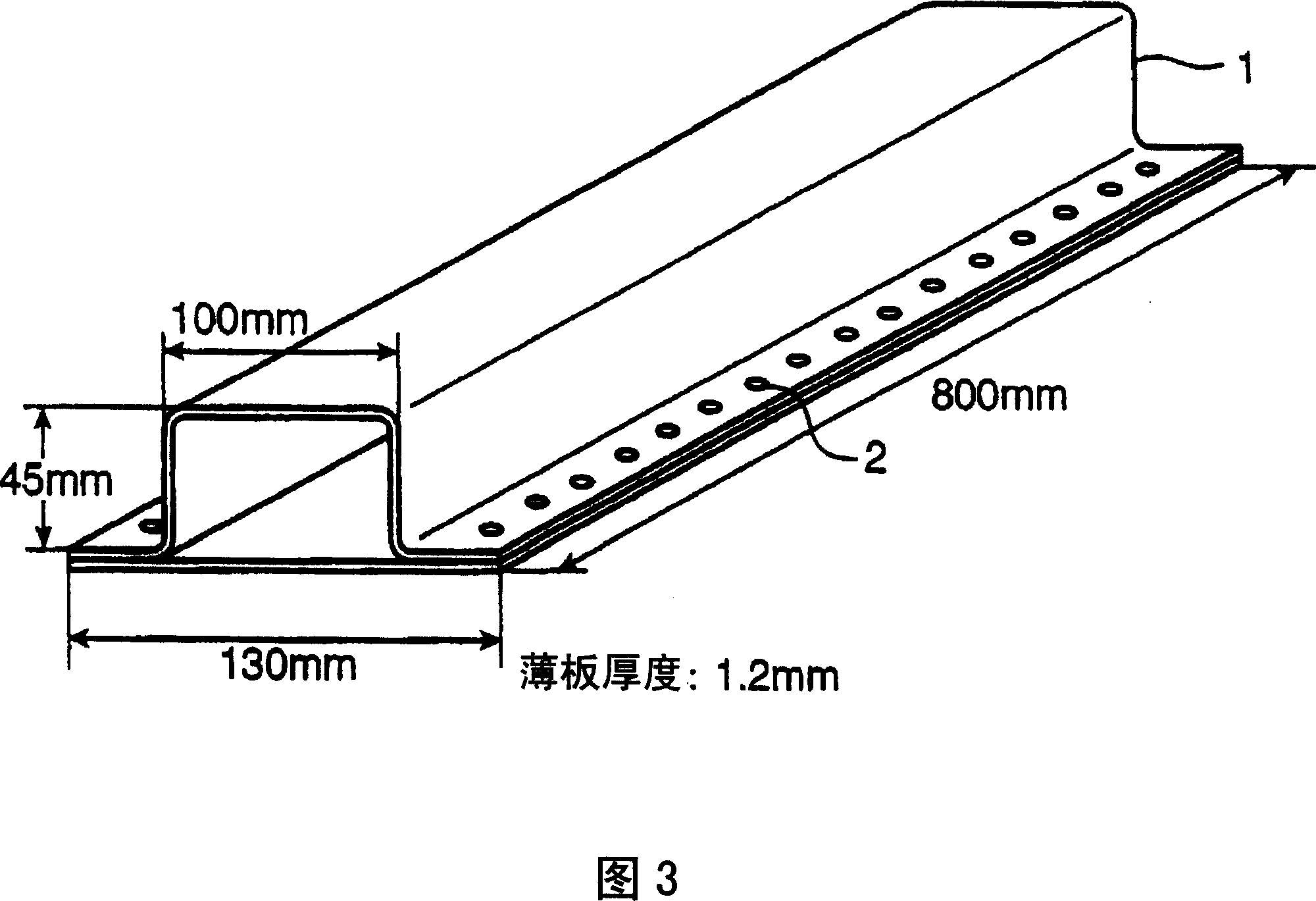

[0139] The experimental steel No.A-1~Y-1 composed of the composition listed in Table 1 was vacuum smelted to make the slab for the experiment, followed by the following procedures (hot rolling→cold rolling→continuous annealing) to obtain a plate thickness of 3.2 After the hot-rolled steel sheet of mm, the surface scale was removed by pickling, and then cold-rolled until it became 1.2 mm thick. Start temperature (SRT) at : 1150~1250℃ for 30 minutes

[0140] Finish temperature (FDT): 850°C

[0141] Cooling rate: 40°C / s

[0142] Coiling temperature: 550°C

[0143] Cold rolling rate: 50%

[0144] For each experimental steel in the , after holding at point A3 + 30°C for 120 seconds, it was rapidly cooled (air-cooled) to To°C in Table 2 at an average cooling rate of 20°C / s, and held at this To°C at 240°C. seconds. Then air-water cooled to room temperature.

[0145] In addition, No. 116 in Table 2 is used as a comparative example. In order to produce a martensitic steel of con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com