Steel for high pressure hydrogen gas environments, steel structure for high pressure hydrogen gas environments, and method for producing steel for high pressure hydrogen gas environments

A high-pressure hydrogen gas and manufacturing method technology, applied in the direction of manufacturing tools, outer walls of container structures, pressure vessels, etc., can solve the problems of high cost, high price of hydrogen structures, low strength, etc., and achieve simple hydrogen embrittlement resistance, Effect of improving fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

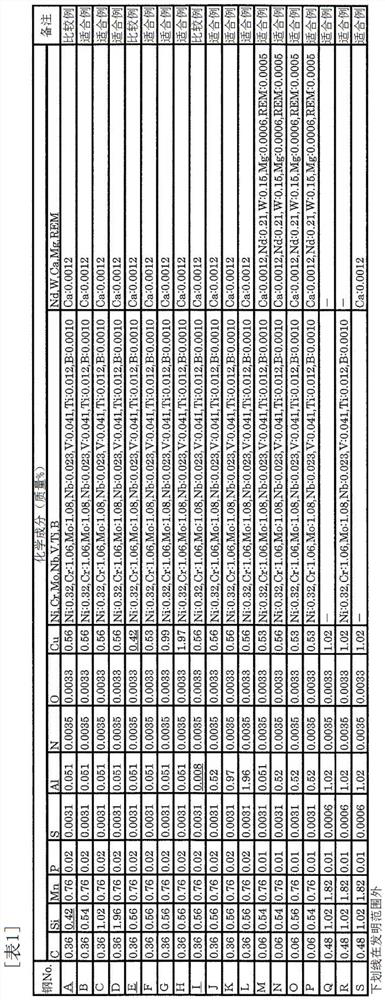

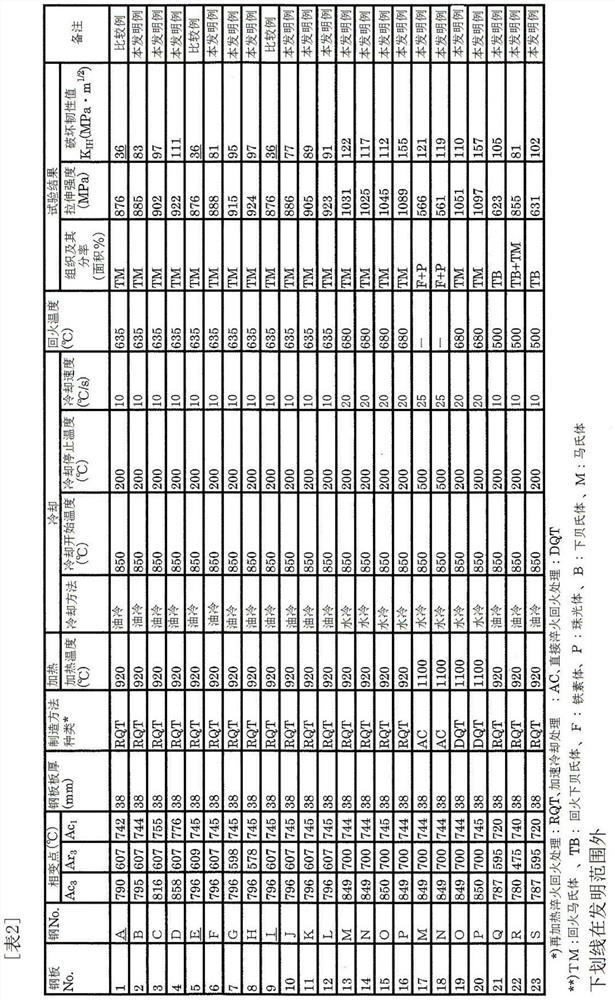

[0131] Molten steel having the composition shown in Table 1 was melted in a converter, and continuously cast to form a cast slab (slab: wall thickness: 250 mm). The obtained slab was heated and hot-rolled to form a thick steel plate (thickness: 38 mm), cooled to room temperature once, and reheated, quenched and tempered under the conditions shown in Table 2 (steel plate No. 1 to No.16, No.21~No.23). It should be noted that the quenching treatment is water cooling or oil cooling.

[0132] In addition, the obtained slab was heated under the conditions shown in Table 2, hot-rolled, and made into a thick steel plate with a predetermined thickness (38mm), and then accelerated cooling was carried out under the conditions shown in Table 2 ( steel plate No.17, No.18).

[0133] In addition, the obtained slab was heated under the conditions shown in Table 2, and hot rolled to form a thick steel plate with a predetermined thickness (38mm), followed by direct quenching under the conditi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com