High strength spring steel having excellent hydrogen embrittlement resistance

A high-strength, spring steel technology, used in low internal friction springs, springs/shock absorbers, heat treatment equipment, etc., can solve problems such as difficulty in achieving hydrogen embrittlement resistance, and achieve low alloying elements and excellent recyclability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

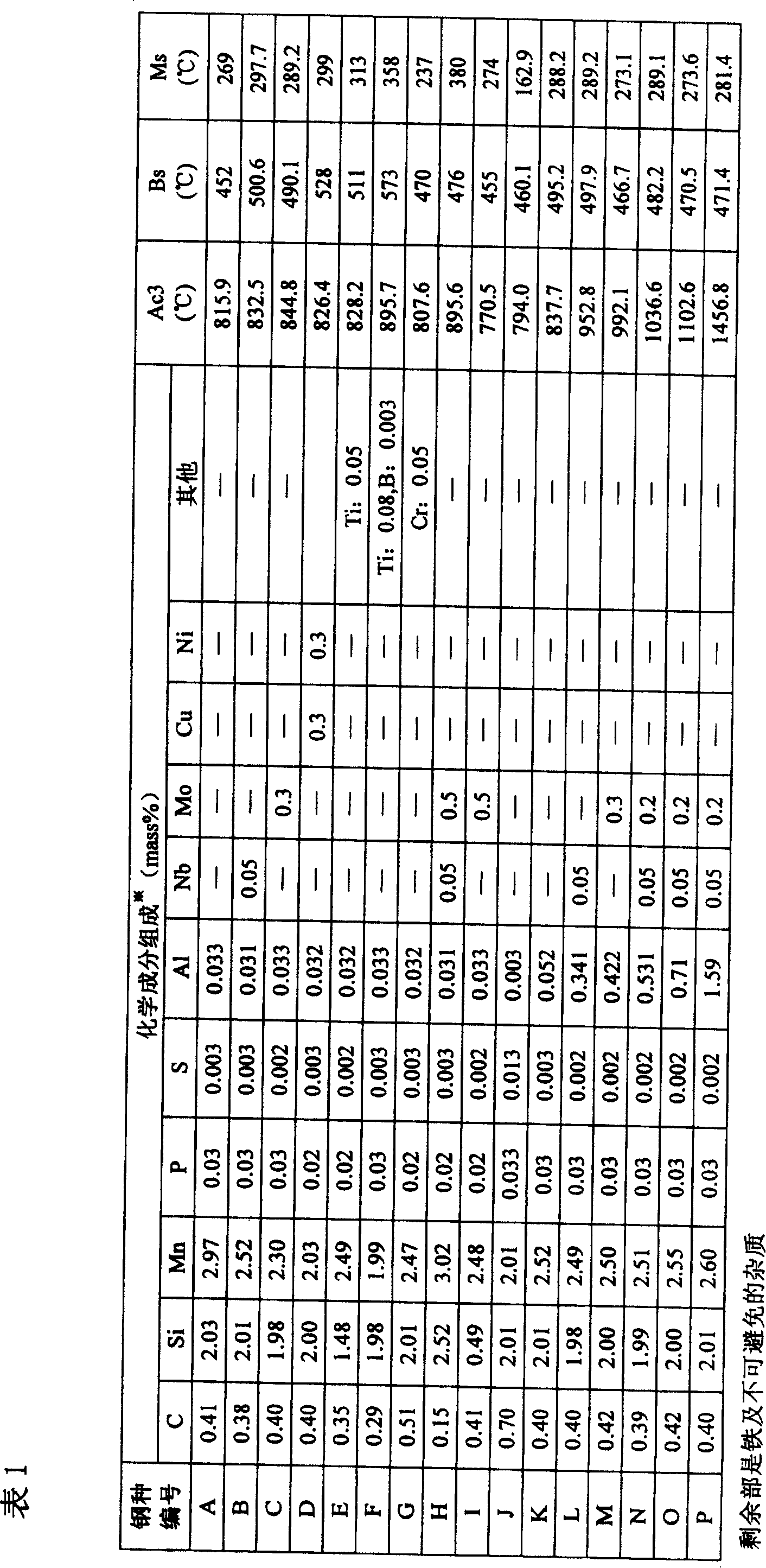

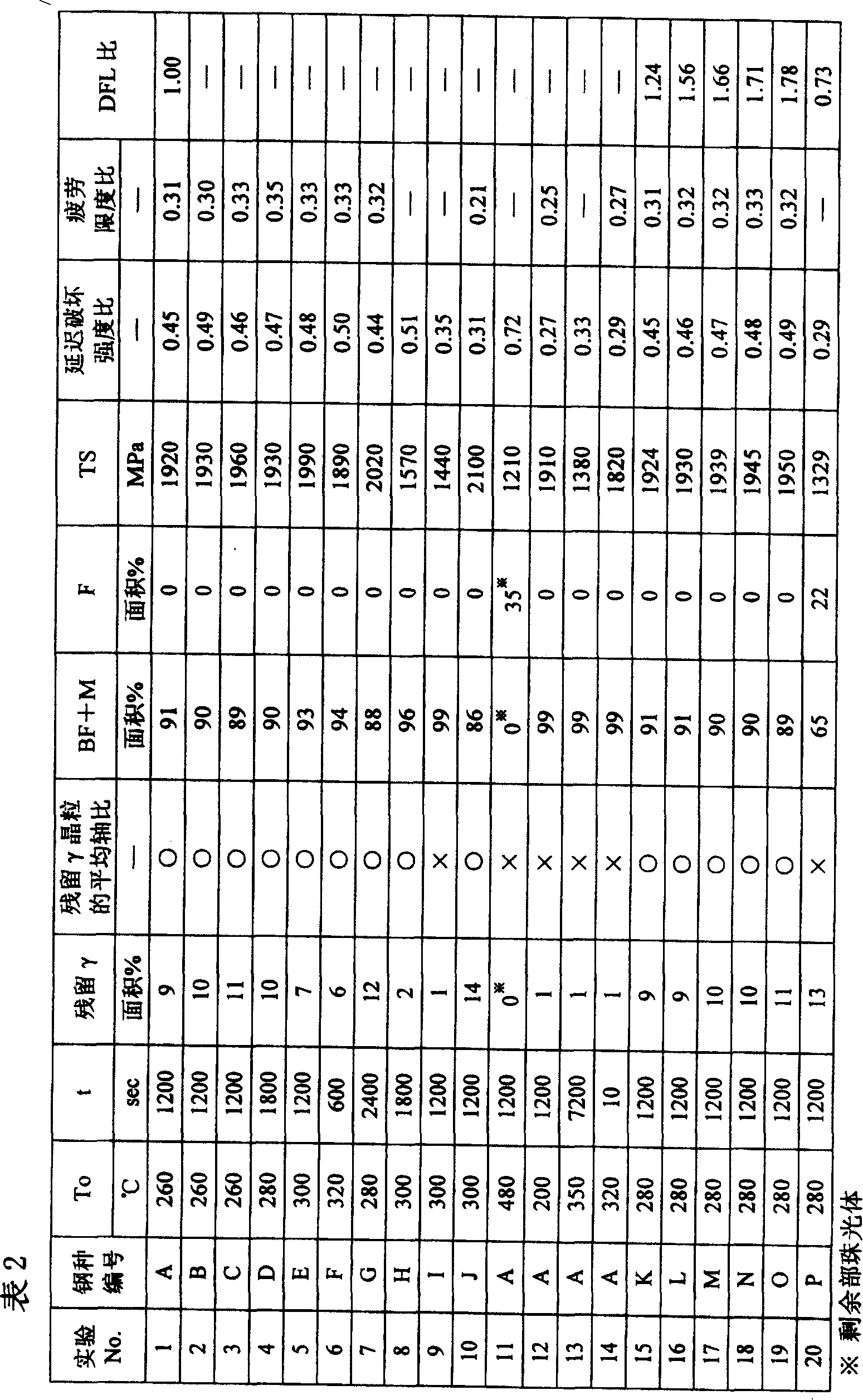

[0096] After smelting No.A to P steel materials composed of the composition listed in Table 1, a 115 mm square billet was produced by forging, and rolled to Afterwards, the drawing process achieves Heat treatment (tempering) was performed after cutting this wire-drawn material into lengths of 300 mm. The heat treatment, in (A 3 point + 30°C) for 5 minutes, then cooled to To°C in Table 2 at 10°C / s, and kept at this temperature (To°C) for t seconds as shown in Table 2, after which naturally cooled spring steel was obtained.

[0097] The metal structure, tensile strength (TS), elongation [full extension (E1)], hydrogen embrittlement resistance, and fatigue properties of each spring steel thus obtained were investigated in the following manner.

[0098] [Observation of metal structure]

[0099] In the measurement area (approximately 50 μm × 50 μm, measurement interval: 0.1 μm) at any position in the cross-section of the obtained sample at the position of 1 / 2 radius, the baini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com