Steel structure for hydrogen which exhibits excellent hydrogen embrittlement resistance properties in high-pressure hydrogen gas, and method for producing same

A technology of high-pressure hydrogen gas and manufacturing methods, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of not easy hydrogen embrittlement, increased risk of hydrogen embrittlement damage, high price of hydrogen storage containers, etc., and achieve hydrogen embrittlement resistance Excellent properties and improved hydrogen embrittlement resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

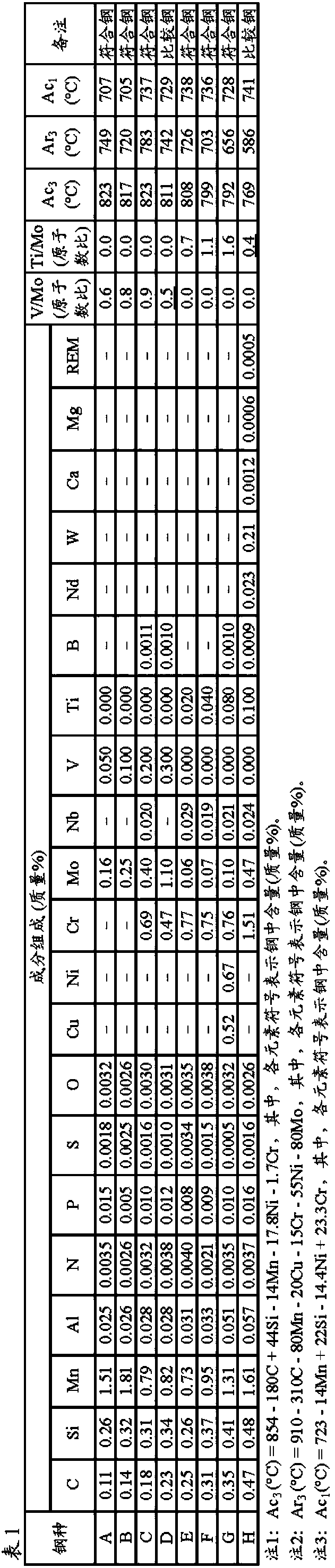

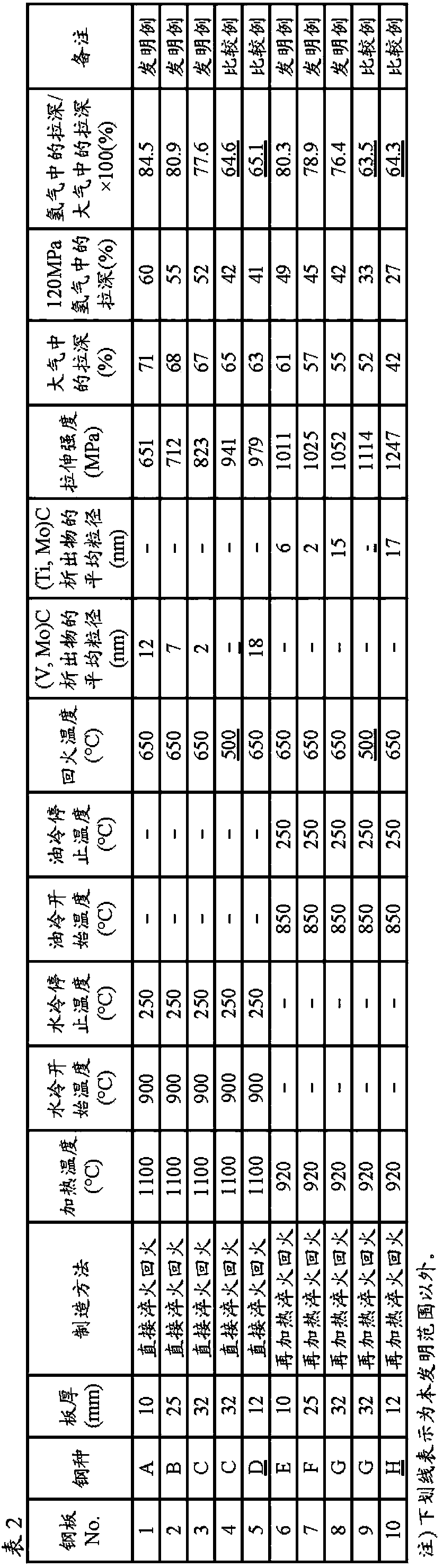

[0134] Hereinafter, examples for verifying the effects of the present invention will be described. In the following examples, the manufacturing method and characteristic evaluation of the steel plate were used to simulate the manufacturing method and characteristic evaluation of the pipeline for hydrogen and the hydrogen storage container. Specifically, when the manufacturing method is direct quenching and tempering, the case of a hydrogen pipeline is simulated, and when the manufacturing method is reheating quenching and tempering, a case of a hydrogen storage container is simulated.

[0135] Steels A to H with the compositions shown in Table 1 were melted and cast into slabs, heated to the heating temperature shown in Table 2, hot rolled, and then directly quenched by water cooling under the conditions shown in Table 2 Tempering treatment was carried out to produce steel plates No. 1 to 5.

[0136] In addition, after casting into slabs, steel plates were produced, and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com