Device and installation for injecting particulate materials into a chamber, and corresponding method

A technology for injecting equipment and substances, which is applied in the field of processing substances in devices and devices for processing substances, can solve problems such as energy consumption, uncompetitive operating costs, and limited applications, and achieve the effect of strong leakage risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

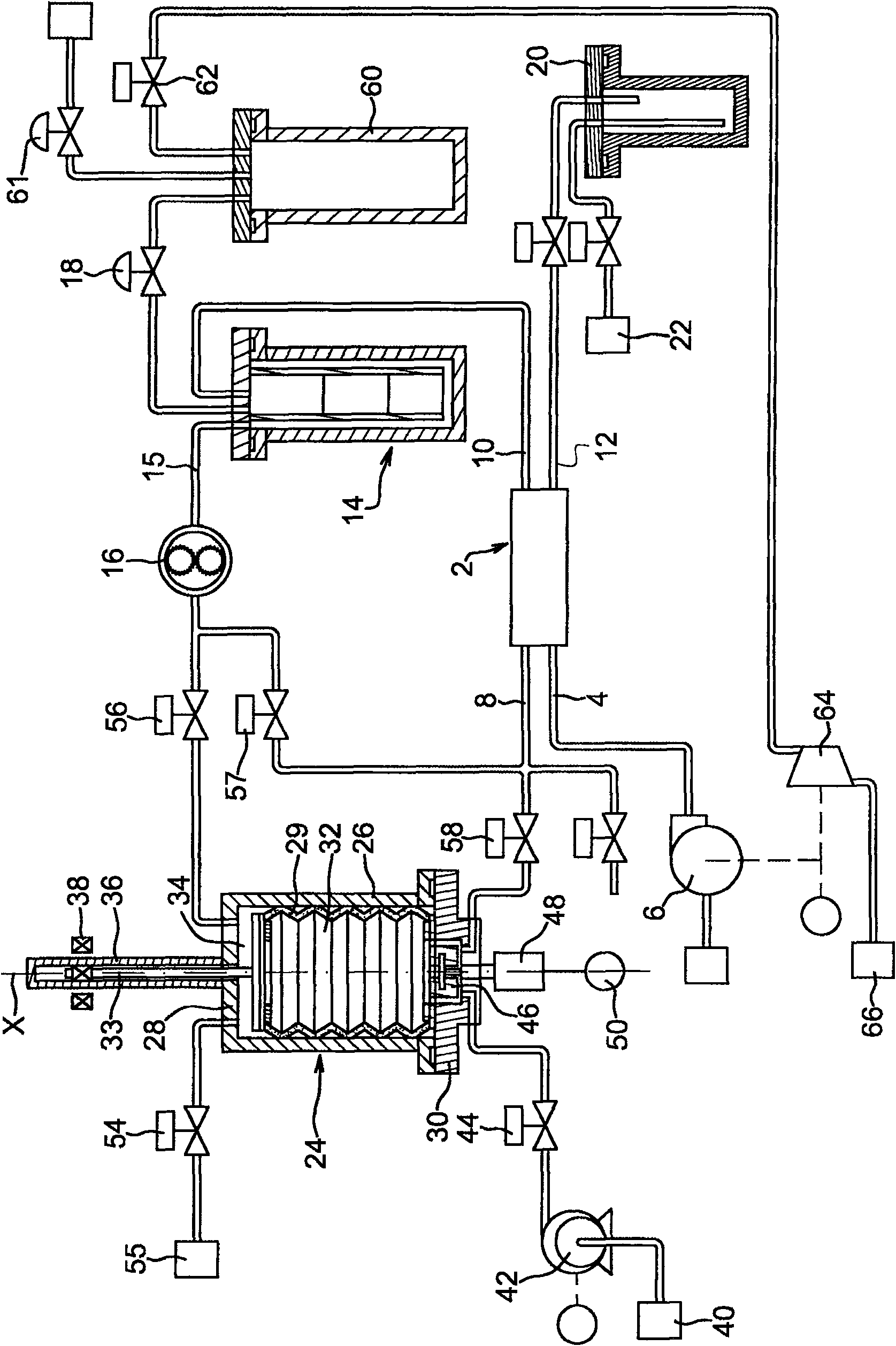

[0023] Other features and advantages of the invention will become apparent after reading the following description of embodiments, given for illustrative purposes, with reference to a single figure.

[0024] The apparatus for treating the waste and the supercritical water oxidation method are described below. The reaction is carried out in reaction vessel 2. This container can be of the usual type. For example, it is possible to use an elongated cylindrical container comprising a tubular body and an inner body housed inside said body, as described in French patent FR 2 814 967 . The reaction vessel is not part of the invention. Therefore no further description is given here.

[0025] Compressed air is supplied to the reaction vessel 2 through the inlet 4 at a nominal flow rate. A high pressure compressor 6 injects air directly into the reaction zone from ambient air or from the headspace of the waste storage tank, which may allow its replenishment.

[0026] Waste material...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap