Vortex magnetic separator

A magnetic separator, eddy current technology, applied in magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of short bouncing distance of non-ferrous metals, affecting magnetic separation, mixing of other materials, etc., to improve the separation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

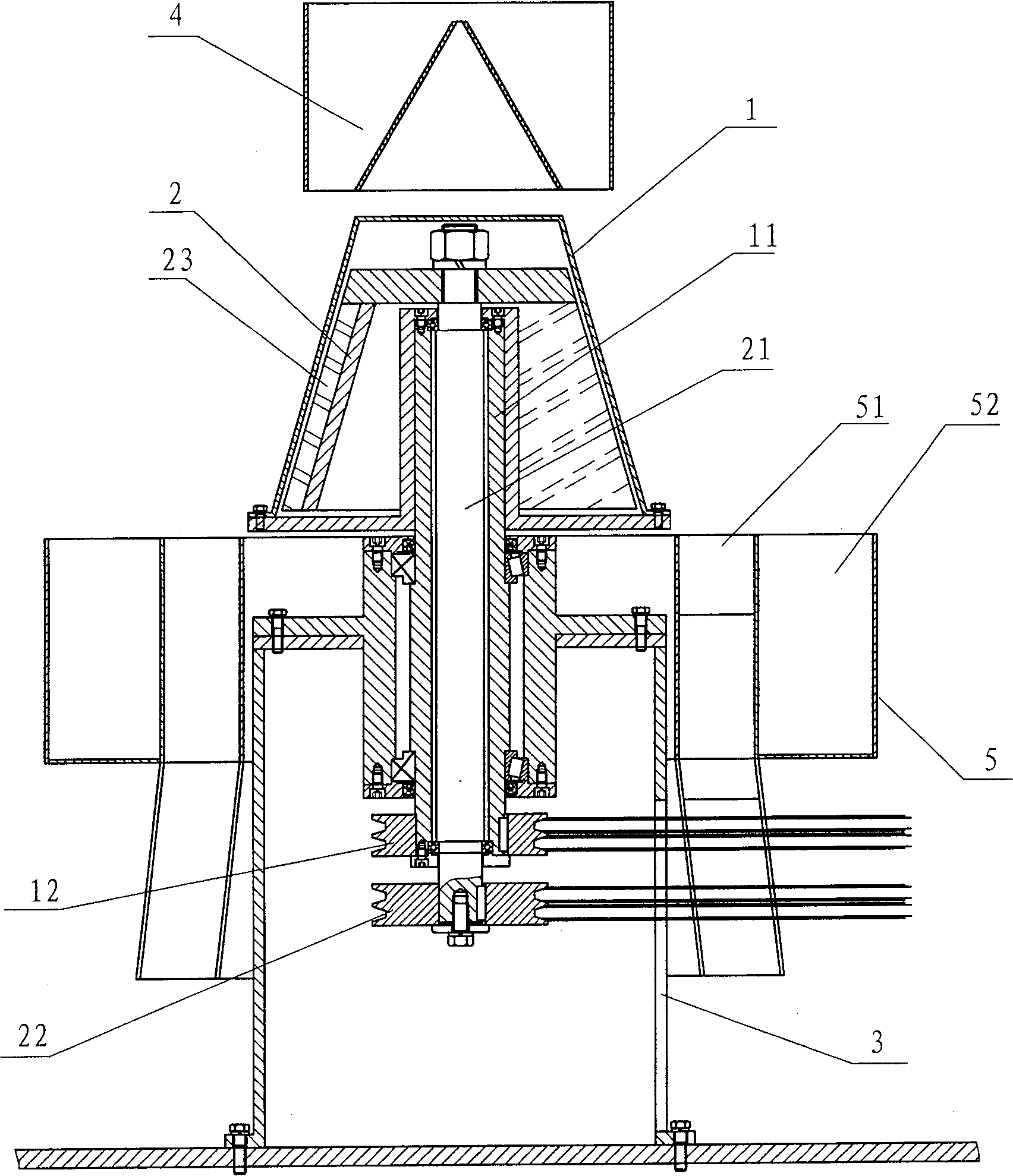

[0009] The reference signs shown in the figure are: outer drum 1, outer drum rotating shaft 11, outer drum driving wheel 12, inner drum 2, inner drum rotating shaft 21, inner drum driving wheel 22, magnetic unit 23, rack 3, blanking Port 4, feed port 5, inner ring 51, outer ring 52.

[0010] In the embodiment of the present invention, during the working process, the inner drum 2 and the outer drum 1 rotate in the opposite direction or in the same direction at different speeds, thereby generating an alternating magnetic field outside the outer drum, and bulk materials fall from the discharge port 4 to the outer drum of the outer drum. On the cone surface, non-metallic materials are thrown into the inner ring 51 of the material inlet 5 under the action of the centrifugal force and gravity of the outer drum 1, and the non-magnetic metal in the material flow bounces to the outer ring of the material inlet 5 under the action of the eddy current 52, so as to achieve the purpose of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com