Method of constructing a thin film mirror

A thin-film mirror and structure technology, applied in instruments, installations, optics, etc., can solve the problems of inability to use and the geometric shape of the thin-film mirror is not accurate enough, and achieve the effect of low price and improved mirror price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

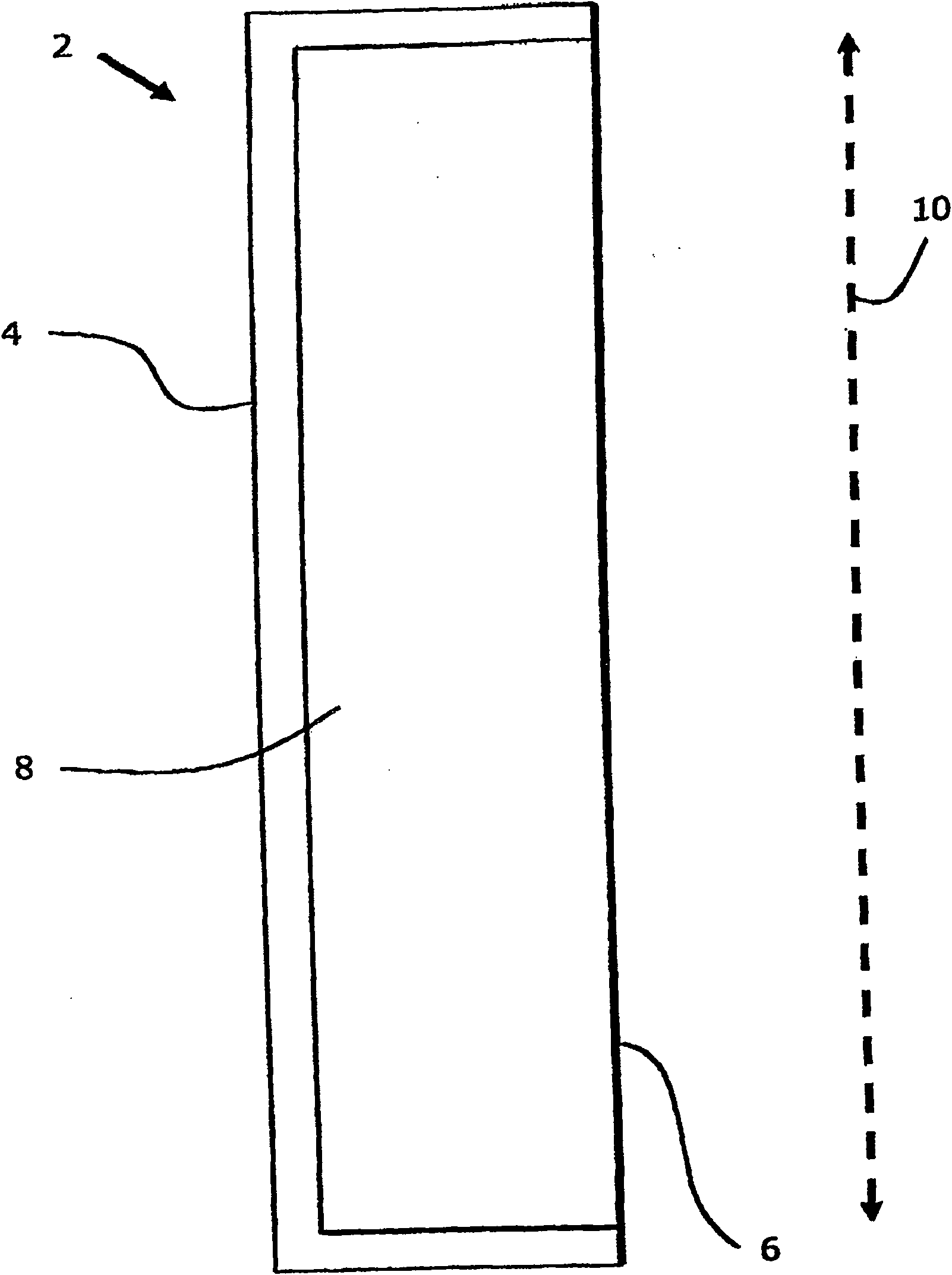

[0051] refer to figure 1 , the device 2 shown comprises a suction chamber 4 with a membrane mirror 6 attached to the edge of the suction chamber 4 . The air pressure in the interior 8 of the suction chamber 4 is not reduced. In other words, no partial vacuum is applied. The film 6 is thus not under tension and remains planar between the edges of the suction chamber 8 . The full usable width 10 of the suction chamber 8 is indicated by dashed lines.

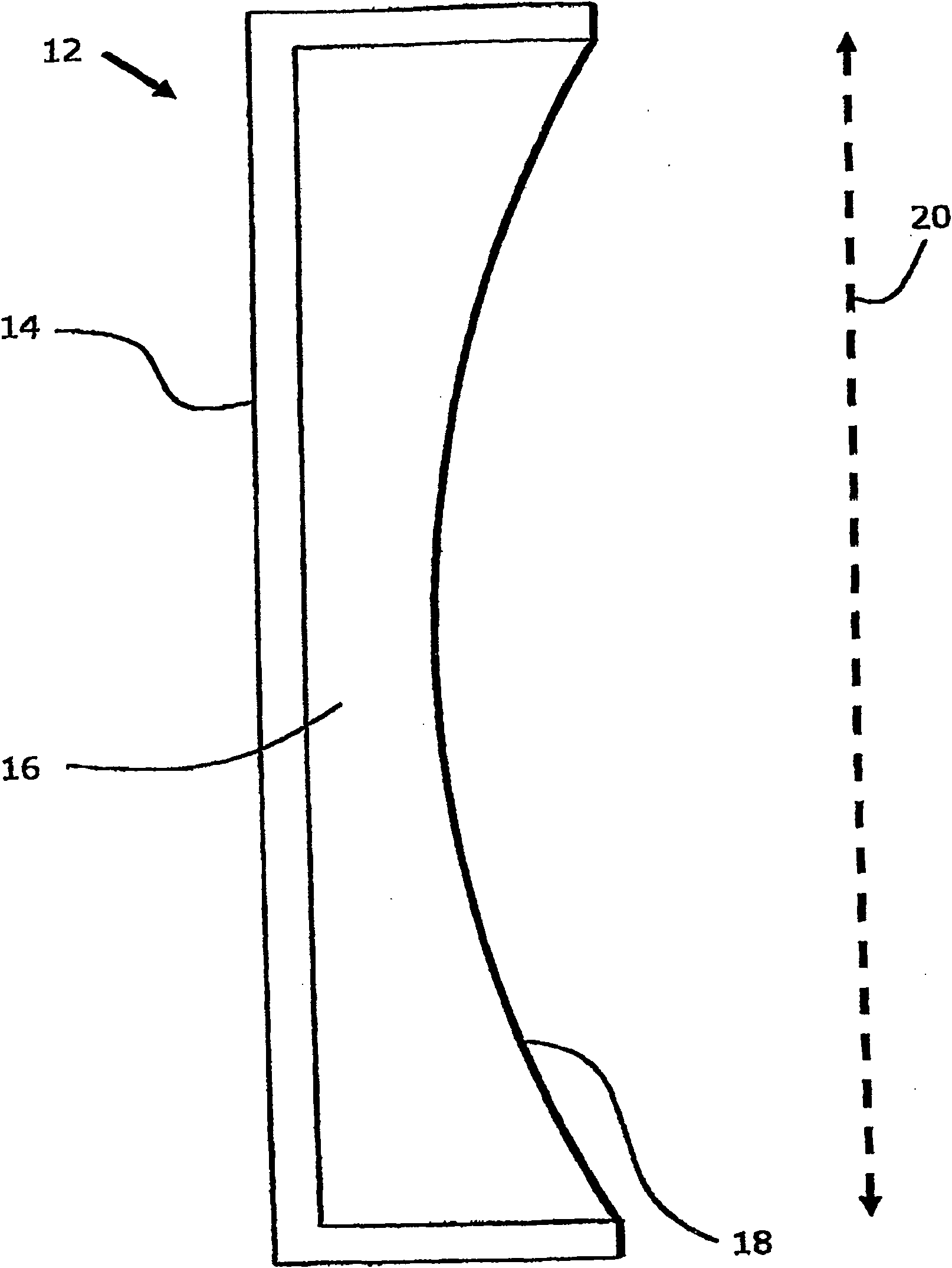

[0052] figure 2 Apparatus 12 including suction chamber 14 is shown. The interior 16 of the suction chamber 14 is already under partial vacuum. Thus, the film 18 has been drawn into the suction chamber 14 as shown. If the membrane 18 were under uniform tension, the shape formed by the membrane 18 in cross-section would be described as an arc of a circle. The radius of this circle will vary with the extent to which the film 18 is sucked into the suction chamber 14 . In this ideal case, the usable area of the membrane 18 i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap