Tooth controlled coded mechanical lock core structure

A technology of mechanical lock cylinder and control mechanism, which is applied in the field of locks, can solve the problems of security impact, leakage of users, inability to use repeated numbers, etc., and achieve the effect of large key volume and high confidentiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

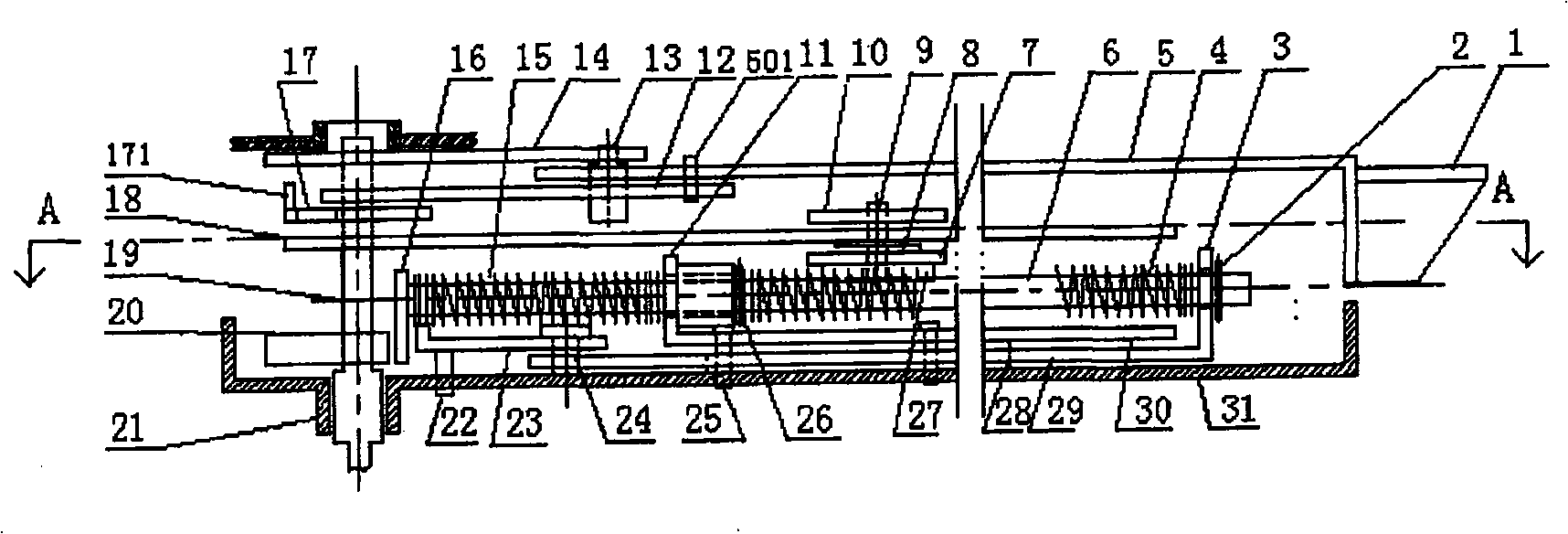

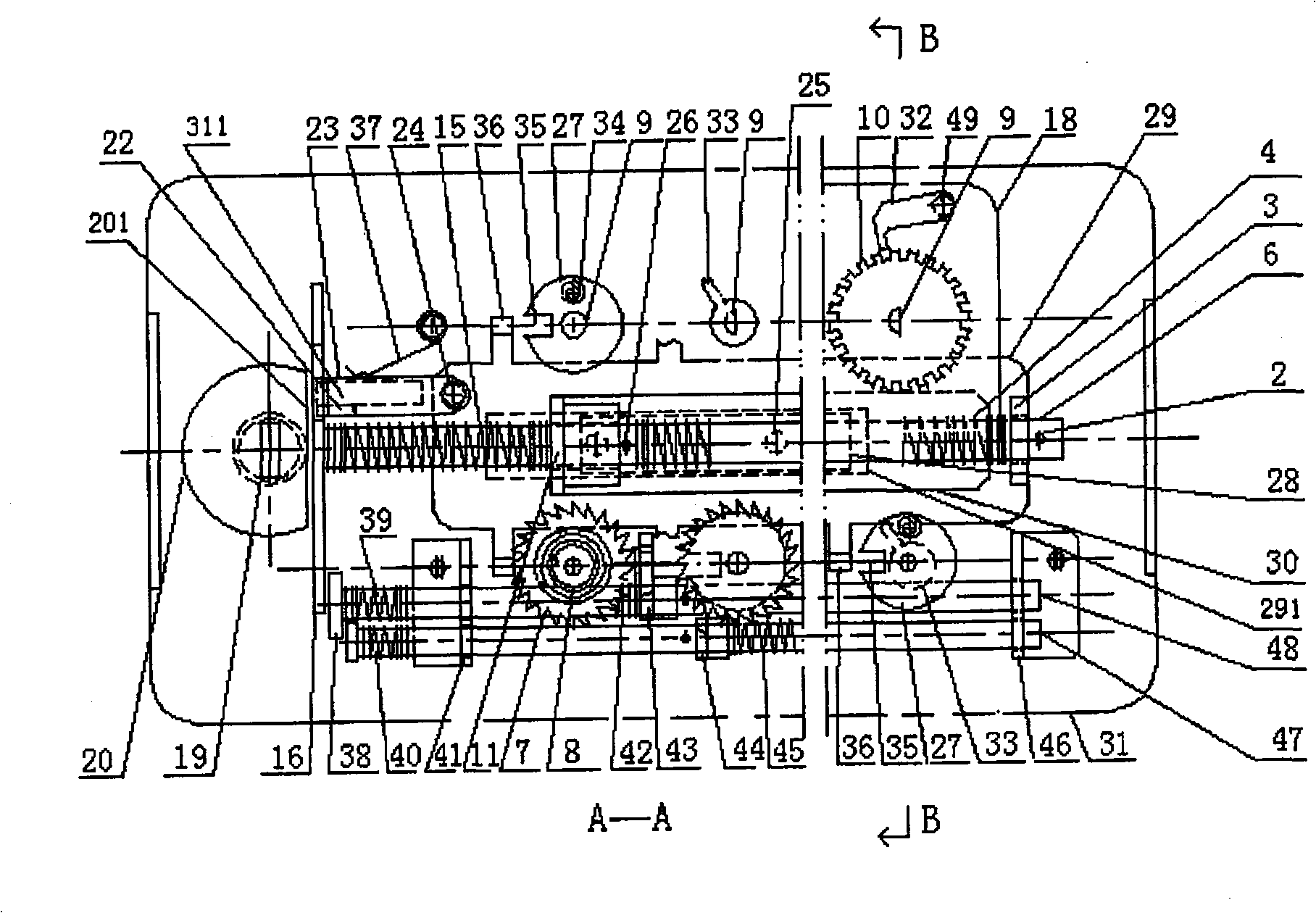

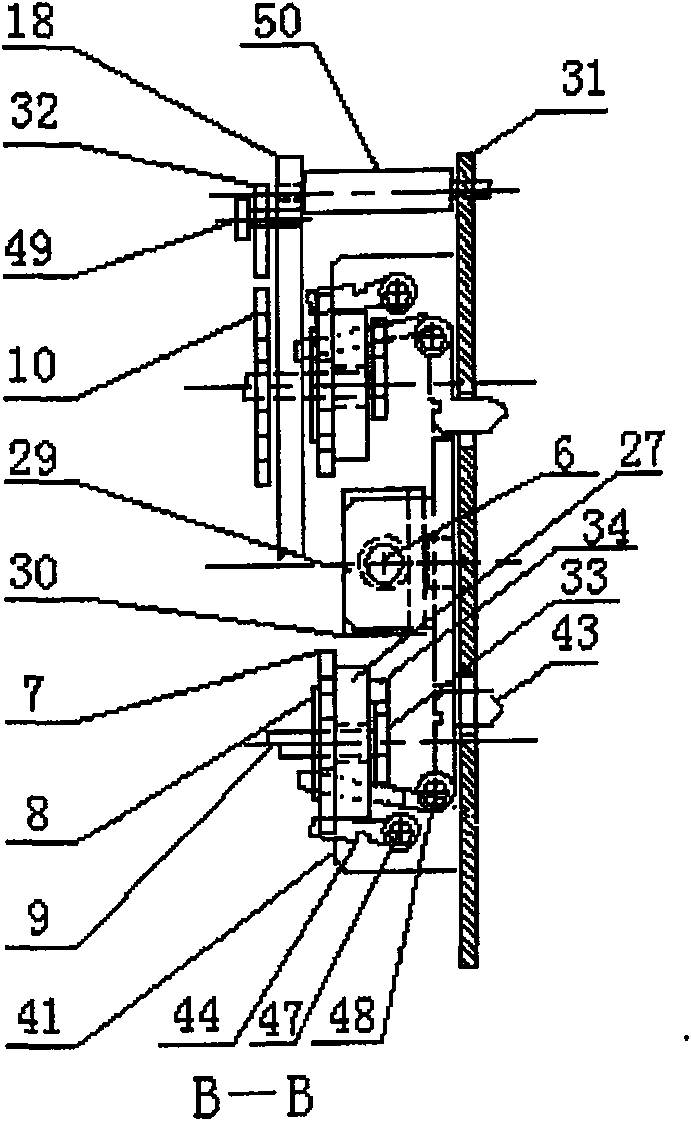

[0022] Lock core structure of the present invention, see Figure 1 to Figure 3 , comprising a central plate 18, on which several cryptographic mechanisms, position-limiting parts 29 and control mechanisms cooperating with the cryptographic mechanisms are provided; On the shaft 9, the code setting part composed of the code adjustment disc 10, the ratchet 7 and the return button 33 is assembled sequentially, wherein the code adjustment disc 10 and the return buckle 33 are arranged at the two ends of the central coupling shaft 9 and are tightly connected to the central coupling shaft 9. Cooperate, the ratchet 7 is located between the center plate 18 and the return button 33 and is matched with the center coupling shaft 9 in clearance, a return spring 8 is provided between the ratchet 7 and the center coupling shaft 9, and the periphery of the code adjustment disc 10 is provided with Corresponding to the number of ratchet teeth on the ratchet 7, corresponding to the tooth mouth of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com