Structure for preventing glue leakage of lens base

A technology for lens mounts and glue overflow, which is applied in installation, optics, instruments, etc., and can solve problems such as glue overflow, poor product appearance, and poor appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] While the invention will be fully described with reference to the accompanying drawings, which contain preferred embodiments of the invention, it should be understood before proceeding that those skilled in the art may modify the invention described herein while still obtaining the benefits of the invention. Therefore, it should be understood that the following description is a broad disclosure for those skilled in the art, and its content is not intended to limit the present invention.

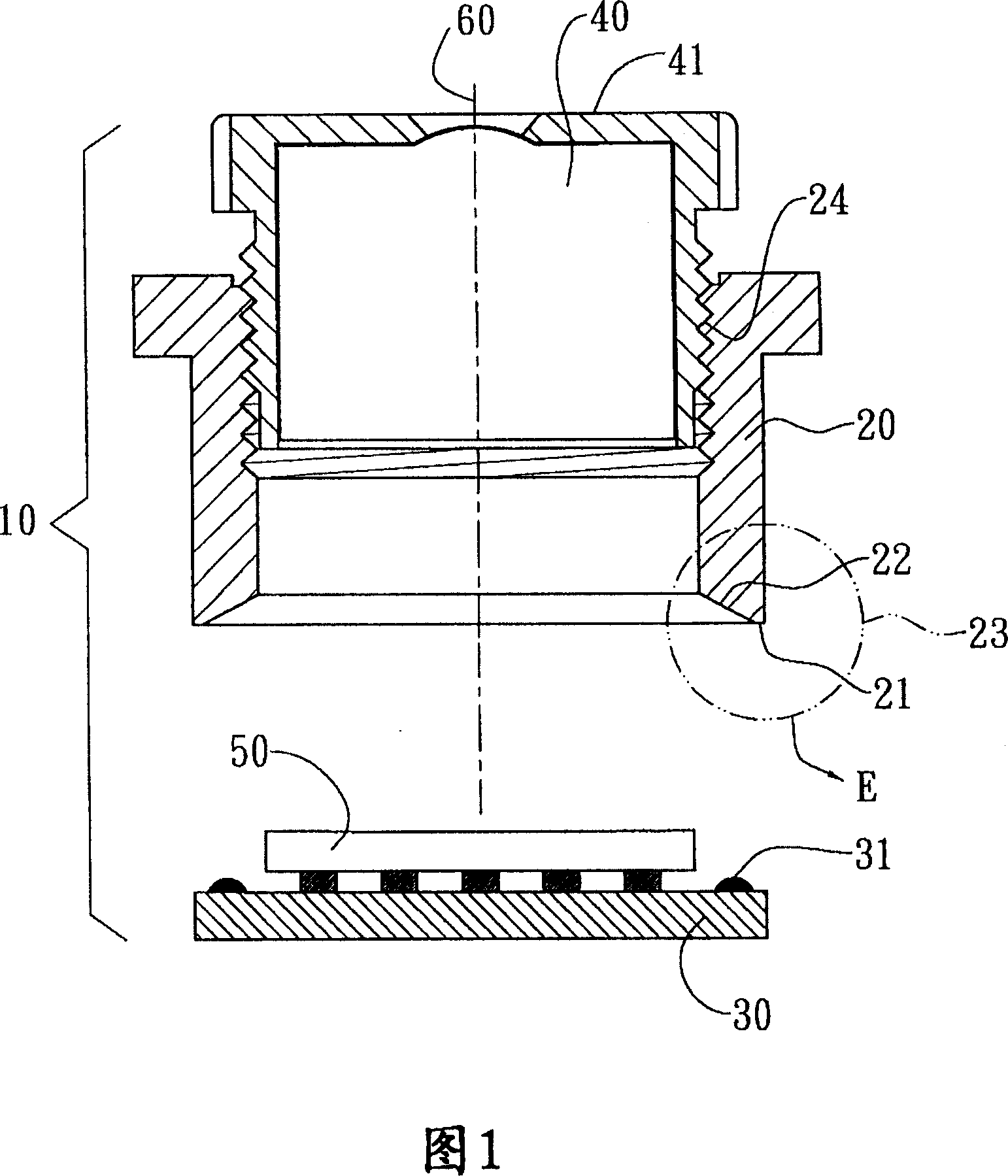

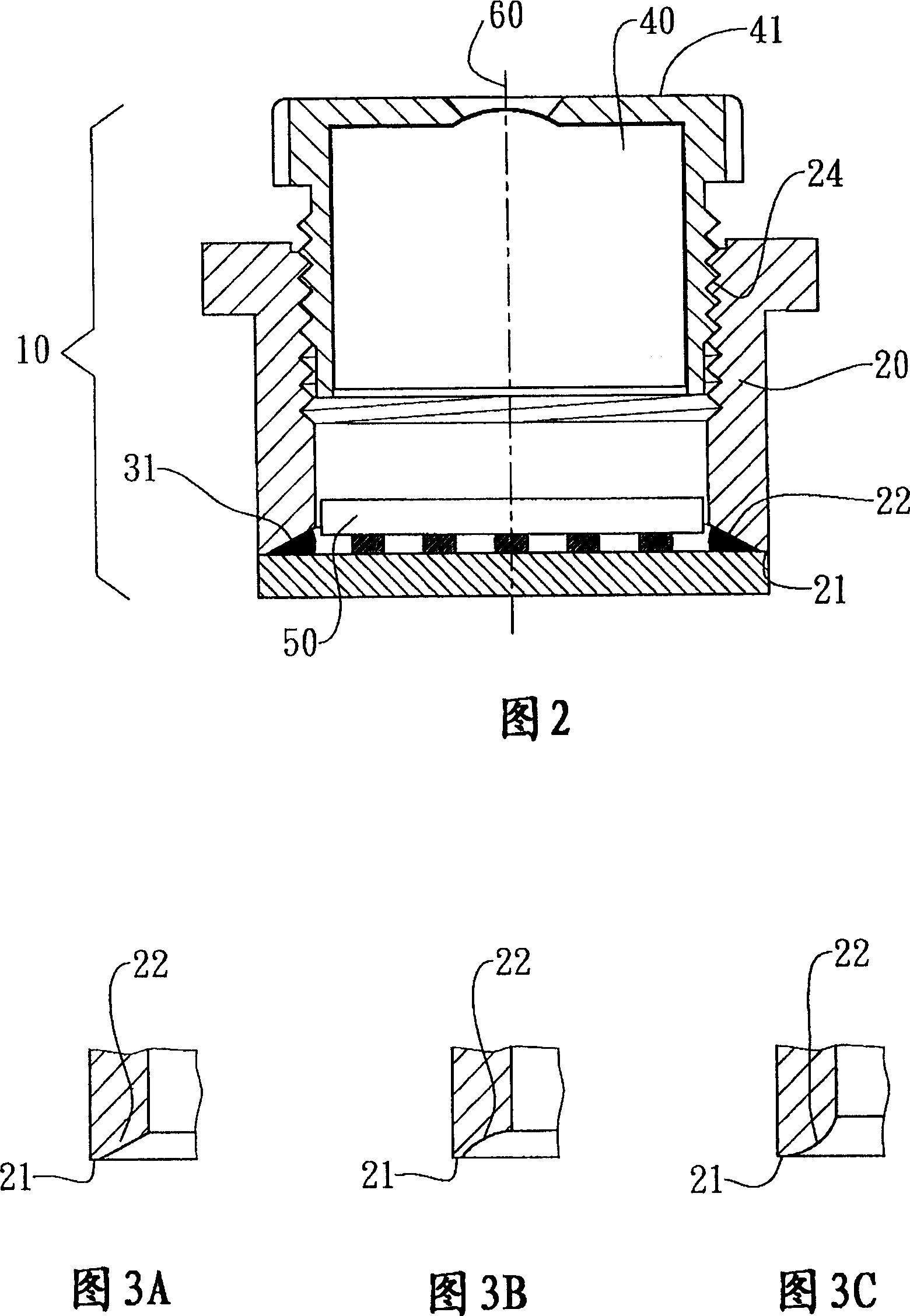

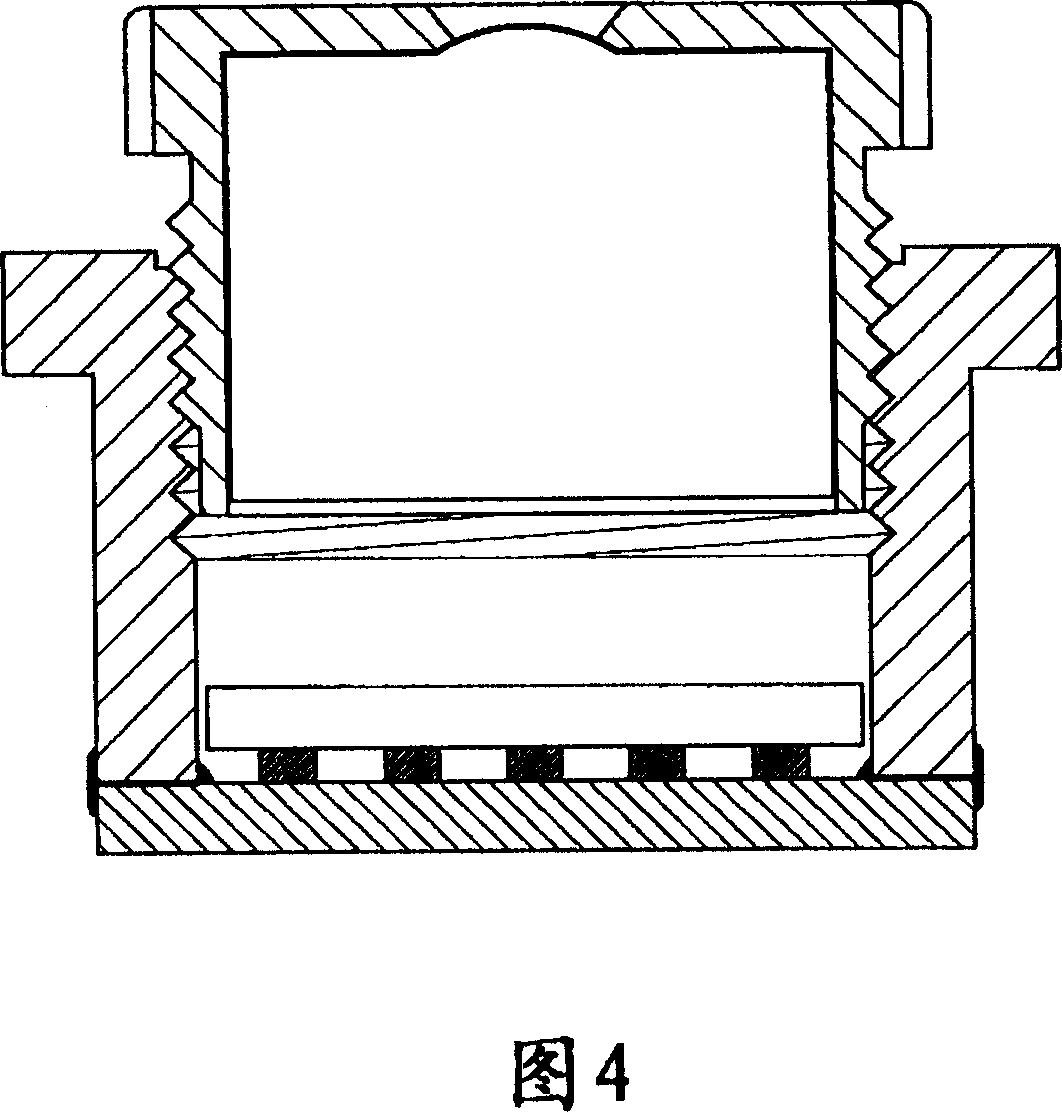

[0022] Please refer to FIG. 1 and FIG. 2 , which respectively show an exploded cross-sectional view and a combined cross-sectional view of the glue overflow preventing structure of the lens mount of the present invention. In the present invention, the lens holder forms a hollow body, and the glue-preventing structure of the lens holder includes a lens group 40, the lens group 40 is surrounded by a lens frame 41, and the lens frame 41 is embedded in the base 20; a base 20 , the base 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com