Pneumatic rivetter without idle operation

A nail gun and functional technology, applied in the field of nail guns, can solve the problems of false firing and low safety performance, and achieve the effect of avoiding false firing and enhancing the safety performance of air defense

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

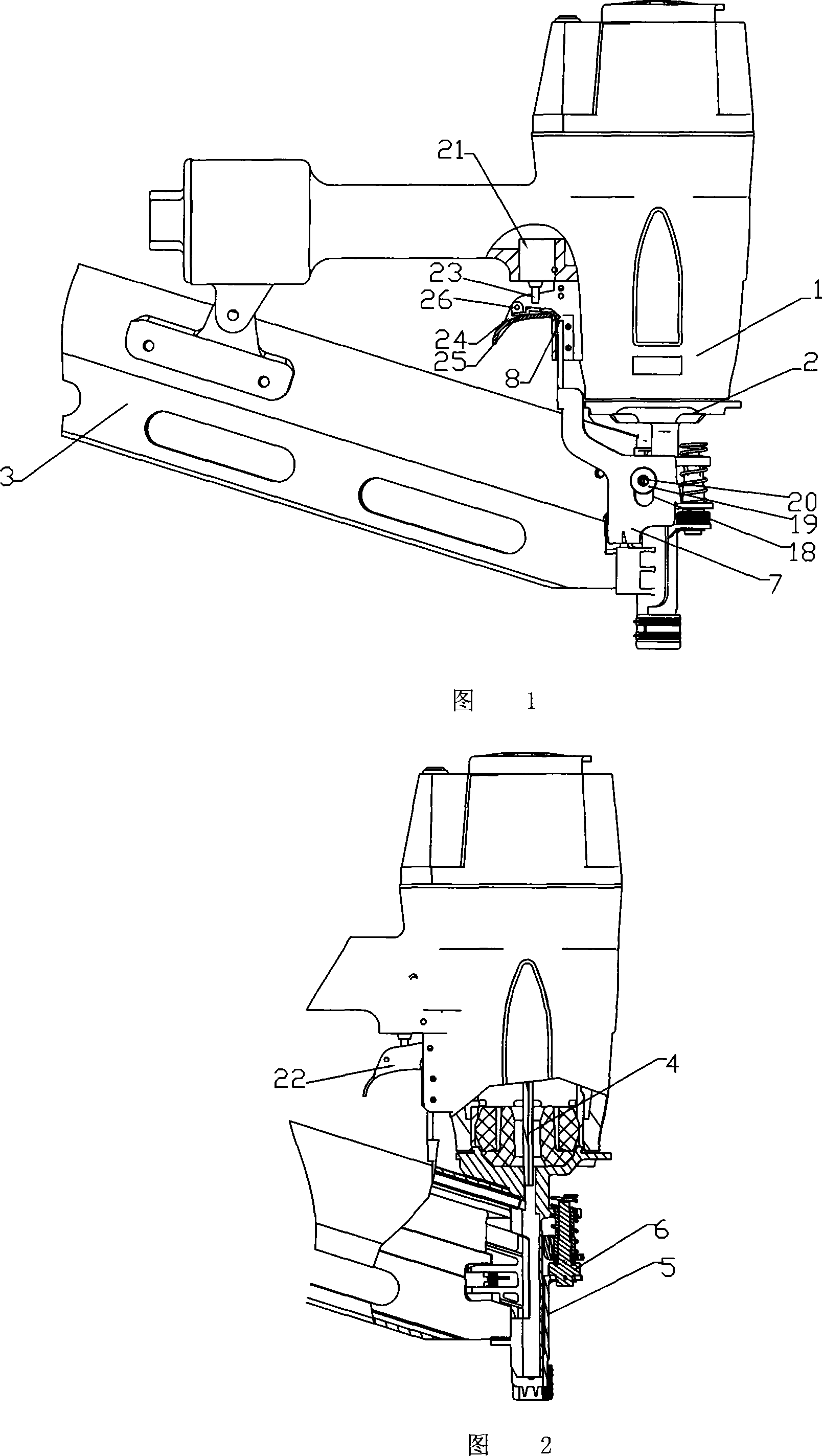

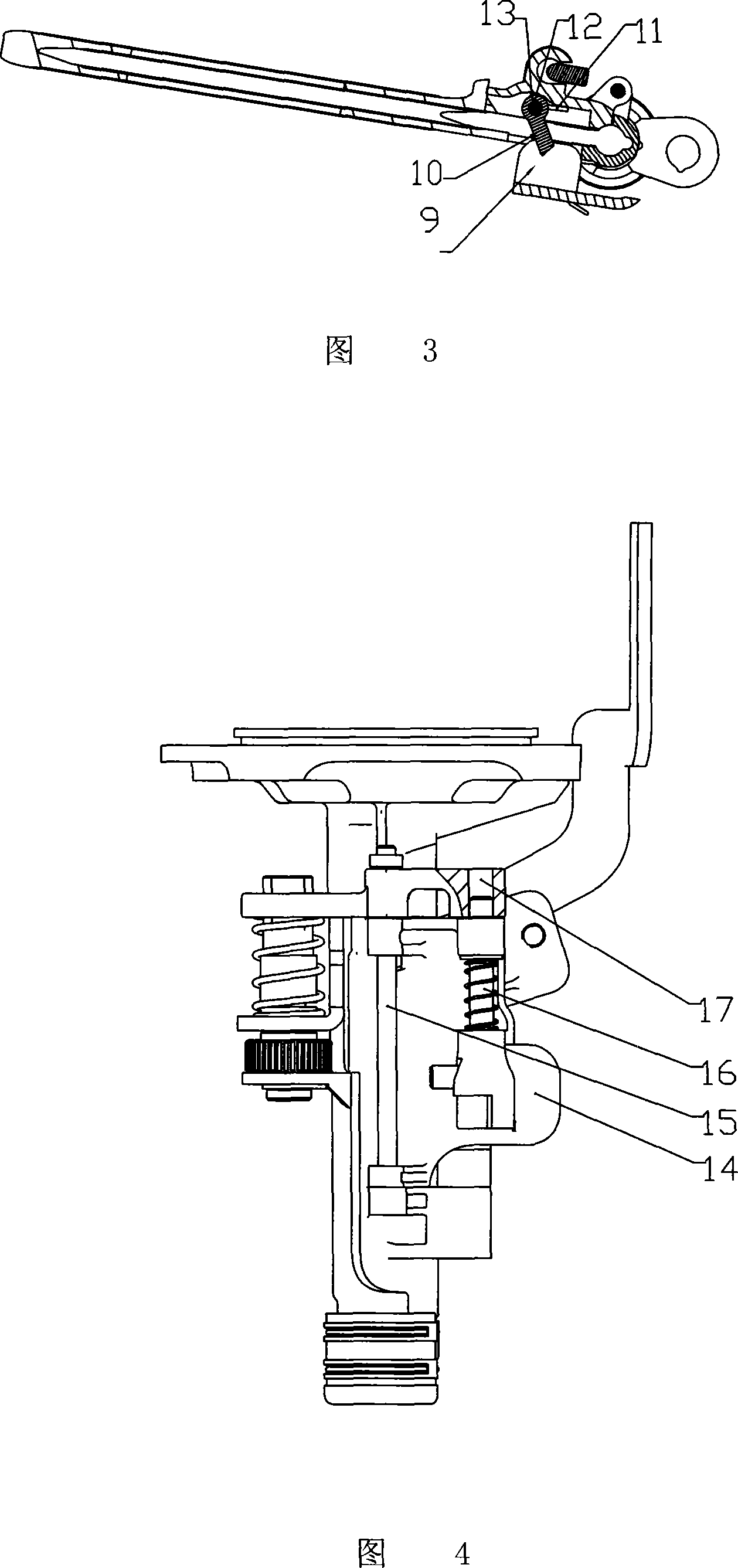

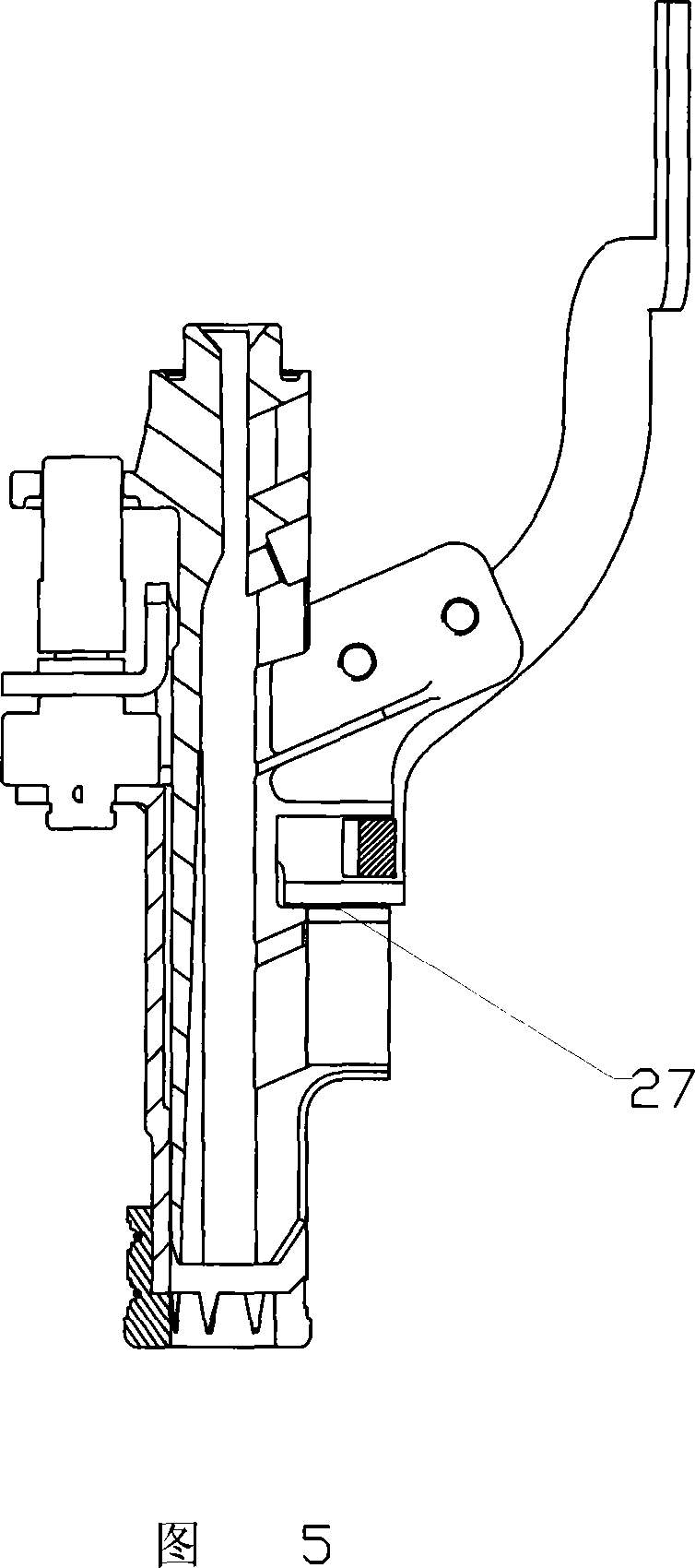

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] Referring to Figures 1 to 4, a nail gun with the function of air defense, including a gun frame 1, a gun nozzle 2, and a nail clip 3, the gun frame 1 is provided with a firing pin 4 and a firing pin activation mechanism, and the firing pin 4 The gun mouth 2 is installed below, and the side of the gun mouth 2 is equipped with a nail clip 3, and the lower part of the gun mouth 2 is covered with a sliding sleeve 5, and the sliding sleeve 5 is connected with the adjusting nut 6 shafts. The adjusting nut 6 is threadedly connected with the curved rod 7, the upper free end 8 of the curved rod 7 is linked with the firing pin activation mechanism, the lower end of the curved rod 7 has a hook 9, and the hook 9 is located at the gun mouth 2 and one side of the junction of the nail clip 3, a nail pressing block 10 is provided on the other side of the junction of the gun mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com