Fire-extinguishing liner and application thereof

A technology of fire extinguishing agent and raw and auxiliary materials, which is applied in fire rescue and other directions, to achieve the effect of controlling explosion power, avoiding waste and loss, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: The manufacture example of building fireproof foam cement.

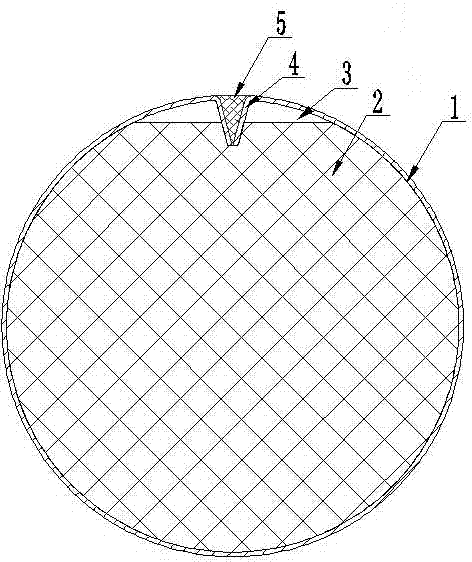

[0033] At first select the thin-walled glass hollow sphere of appropriate volume for use as the raw material of fire extinguishing gallbladder shell 1. Utilize the existing "blowing hole" on the thin-walled glass hollow sphere as the open channel 4, and inject the fire extinguishing agent 2 into liquid carbon tetrachloride [(carbon tetrachloride, CCl4), also known as tetrachloromethane (tetrachloromethane), which is colorless, easily Volatile, non-flammable liquid. With a slightly sweet smell of chloroform. The molecular weight is 153.84, the density is 1.595g / cm3 (20 / 4°C), the boiling point is 76.8°C, the vapor pressure is 15.26kPa (25°C), and the vapor density is 5.3g / L. ], until it basically reaches the channel opening, reserve 10-30% of the gaseous space 3. And the opening channel is firmly and permanently blocked with a sealant to become a plug 5.

[0034] Gently move an appropriate amou...

Embodiment 2

[0036] Embodiment 2: Manufacturing example of building fireproof gypsum indoor partition.

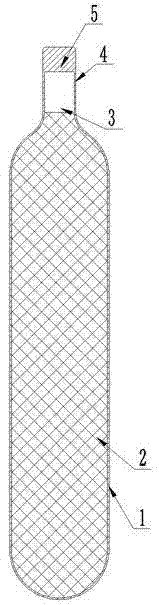

[0037] First select a thin-walled glass tube with an appropriate diameter, melt and sinter one end of the glass tube to close it, and stretch and shrink the other end into a thin tube opening to become the fire extinguishing tank 1 . Then inject the liquid 1211 fire extinguishing agent 2 at the boiling point temperature [the main component is difluoro-chloro-bromomethane (CF2ClBr), which is a gas at normal temperature and pressure, and its boiling point is -4°C. The fire extinguishing agent can be liquefied into a liquefied state when it is under high pressure in a pressurized container. The extinguishing agent sprayed from the cylinder is a mixture of fine liquid droplets and vapour. When the fire extinguishing agent is in contact with the burning material, it is heated to produce bromide ions, which combine with the hydrogen free radicals produced by the burning material, so that the...

Embodiment 3

[0038] Embodiment 3: Application example of building interior decoration partitions.

[0039] The pipes, chains, bags, and net-shaped flexible fire extinguishing bladders, which contain clean water as 95% by volume of fire extinguishing agent 2, are placed in the combustible wood decoration of the decoration project by hanging, hanging, sticking, pasting, and placing. In the space between the parts and the base of the wall. In case of fire, the high temperature of the flame burns the flexible fire extinguishing tank (wall). Leaked extinguishing agent wets unfired wood and burnt debris by leaching. The fire extinguishing agent flowing out can also eliminate the fire source on the ground.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com