Method of printing on towel by four primary colors

A four-primary-color printing technology, applied in the field of textile printing, can solve the problems of roughness of towel fabric, high gray scale and cannot be fully applied, and achieve the effect of bright color, simple production method and strong three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

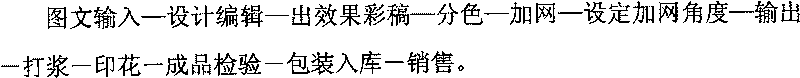

[0049] A method for printing four primary colors on towels, the steps are as follows:

[0050] 1) For the production of plate-making manuscripts, firstly, the images of hand-carved or mechanically engraved manuscripts are made into black-and-white manuscript negatives, and then made into photosensitive printing masters, which are photosensitive copies, and then printed in black and white by printers through laser phototypesetting draft; the main function is to make a photosensitive printing template. Therefore, the plate-making manuscript must be drawn on a light-transmitting substrate, and its image is an opaque ink layer (black or red). The shading density is a key indicator to determine the quality of plate-making manuscripts;

[0051]2), the production of the color separation image manuscript, the color separation image adopts spot color separation and primary color separation. The color is formed into a color image through chromatographic printing, and the design and com...

Embodiment 2

[0097] According to the mass ratio, the seaweed paste is composed of 320-380 parts of water, 3.2-3.8 parts of sodium hexametaphosphate, and 10.5-11.7 parts of sodium alginate after stirring evenly, and then adding water to the total composition of 420-480 parts;

[0098] Ordinary color paste consists of 0.2-0.3 parts of seaweed paste, 0.04-0.05 parts of thickener FS-86, 1-13 parts of dyes, 0.005-0.01 parts of urea, 0.001-0.002 parts of resist salt S, 0.01-0.02 parts of 80-90 ℃ hot water, 0.002-0.003 part of sodium bicarbonate, 0.01-0.02 part of cold water, and then add hydration to synthesize 10 parts in total, and other steps are the same as in Example 1.

[0099] This color paste is suitable for the printing of products with a square meter weight of less than 300 grams and medium and light color patterns.

Embodiment 3

[0101]Beating: The printing of fabrics is mainly printed with reactive dyes, which mainly use the mixed color paste of active thickener FS-86 and seaweed pulp to prepare the color paste:

[0102] According to the mass ratio, the seaweed paste is composed of 330-370 parts of water, 3.4-3.6 parts of sodium hexametaphosphate, and 10.8-11.0 parts of sodium alginate after stirring evenly, and then adding water to form a total of 430-470 parts;

[0103] Black, bright red, and navy blue pastes consist of 0.05-0.11 parts of seaweed paste, 0.043-0.046 parts of thickener FS-86, 1-10 parts of dyes, 0.005-0.01 parts of urea, 0.001-0.002 parts of resist salt S, 0.01-0.02 parts Part 80-90 ℃ of hot water, 0.002-0.003 part of baking soda, 0.01-0.02 part of cold water, add hydration to synthesize 10 parts of total amount, other steps are with embodiment 1.

[0104] This color paste is suitable for the printing of products with a square meter weight of more than 300 grams and medium-dark patter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com