Electric and manual switching device of valve electric actuating mechanism

An electric technology for actuators and valves, applied in the direction of valve operation/release devices, valve devices, engine components, etc., can solve problems such as inability to slip, convenient impact, reliable use, and difficulty in axial sliding of joints 3, etc. Achieve reliable switching and reduce frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

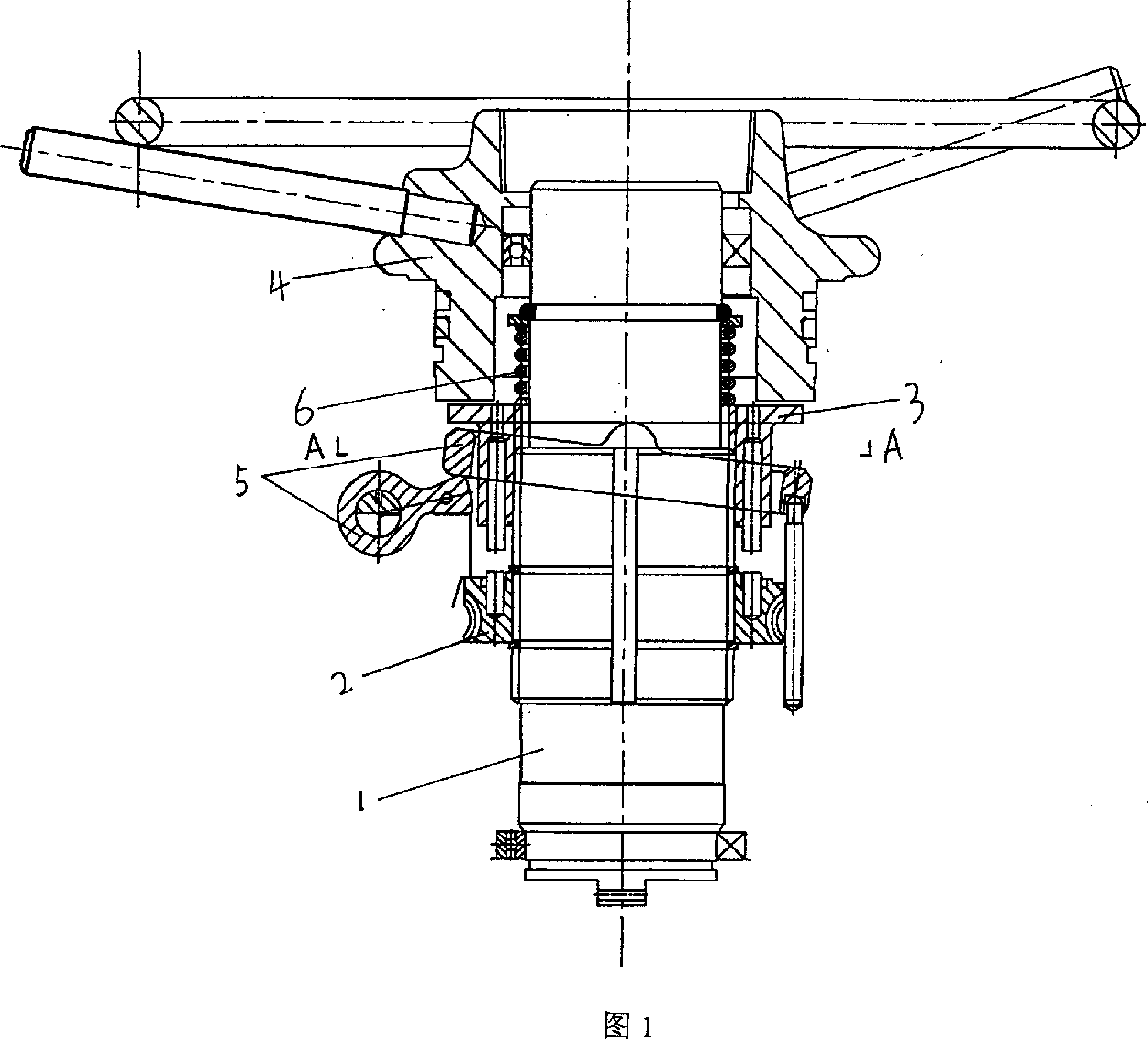

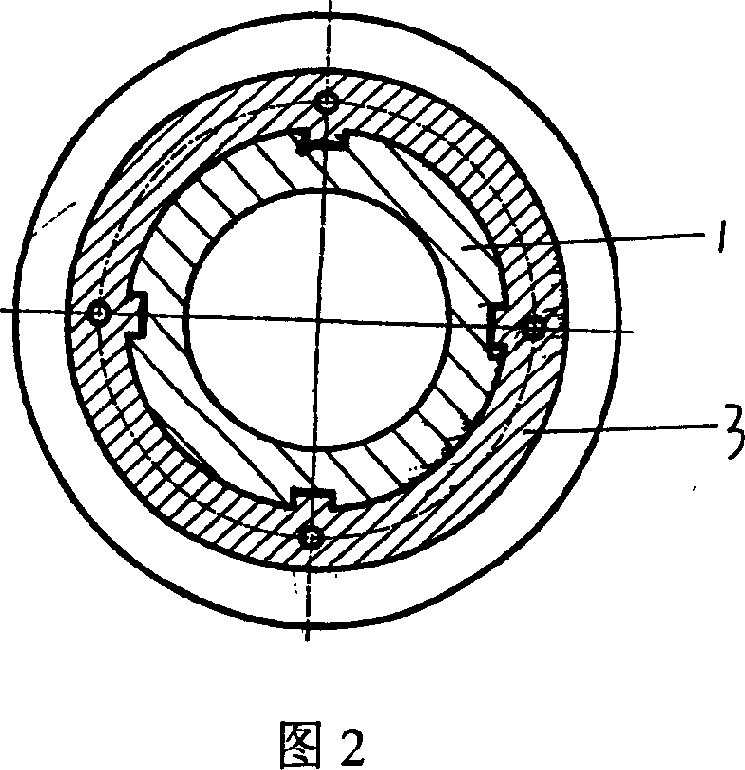

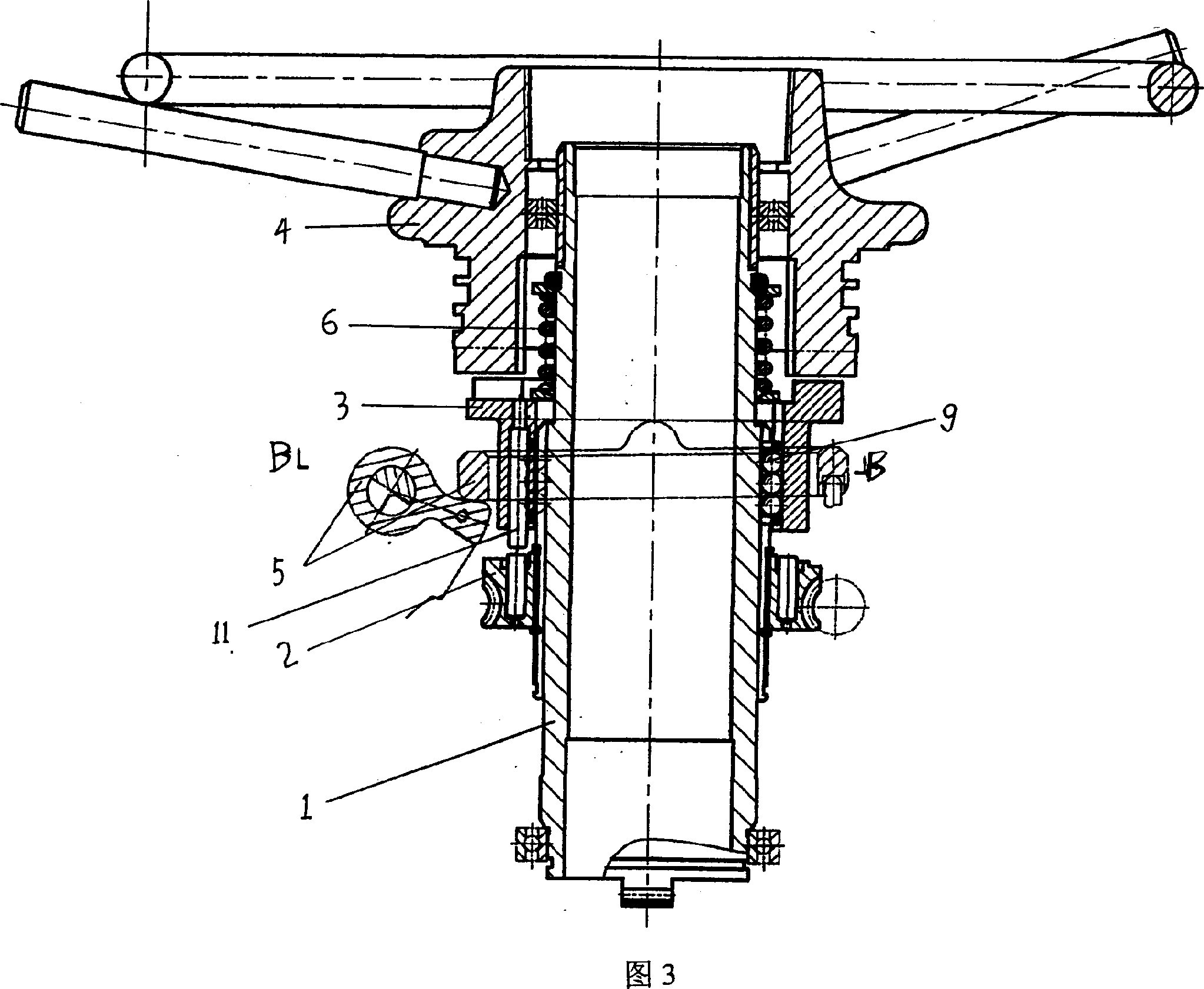

[0015] Among them: 1. Output shaft; 2. Worm wheel; 3. Engagement element; 4. Hand wheel; 5. Switching operation member; 6. Spring; 7. Outer chute; 8. Inner chute; 9. Rolling body; 10. Pin hole; 11, pin.

[0016] The electric and manual switching devices of valve electric actuators shown in Figure 1 and Figure 2 objectively have relatively large frictional resistance when switching, while those provided by the present invention are shown in Figure 3, Figure 4, Figure 5, Figure 6, and Figure 7 , The technical scheme of the electric and manual switching device of the valve electric actuator shown in Figure 8 mainly includes an output shaft 1, a worm wheel 2, an adapter 3, a hand wheel 4, a switching operation member 5, and a spring 6, wherein the adapter 3 is guaranteed to be consistent with the While the output shaft 1 rotates synchronously, it can slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com