Cement grinding aid

A grinding aid and cement technology, applied in the field of cement grinding aids, can solve the problems of no disclosure of cement grinding aids and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

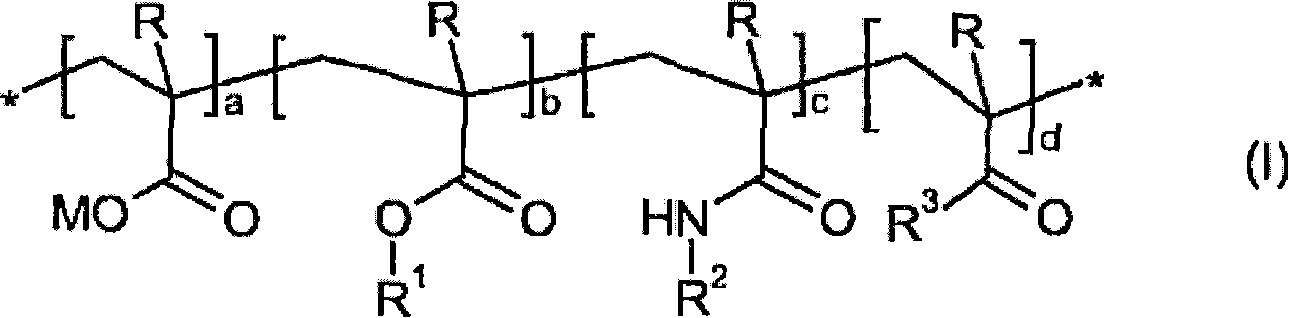

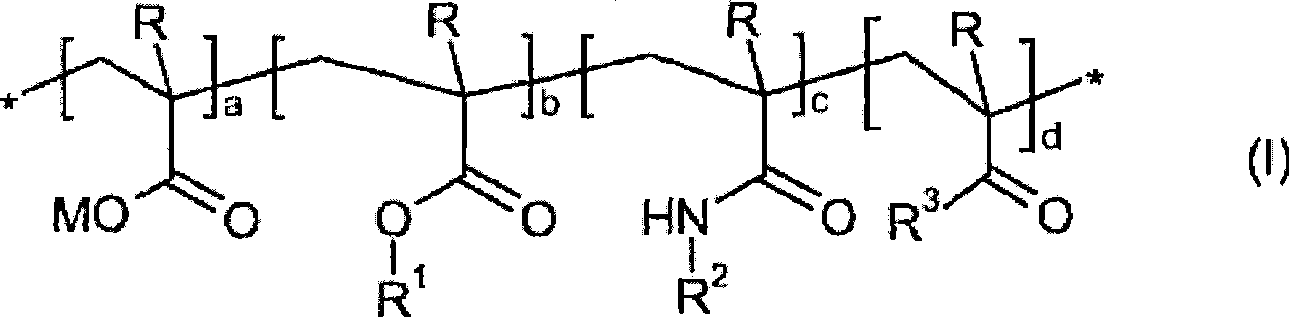

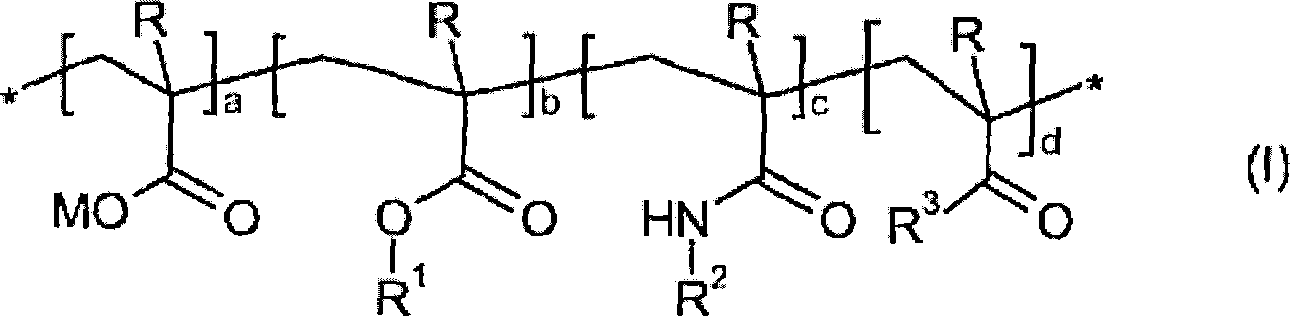

Image

Examples

Embodiment

[0047] Abbreviations used in Table 1

[0048] abbreviation

the meaning

mw *

PEG500

Polyethylene glycol without terminal OH groups

500 g / mol

PEG1000

Polyethylene glycol without terminal OH groups

1000 g / mol

PEG1100

Polyethylene glycol without terminal OH groups

1100 g / mol

PEG2000

Polyethylene glycol without terminal OH groups

2000 g / mol

PEG3000

Polyethylene glycol without terminal OH groups

3000 g / mol

PPG600

Polypropylene glycol without terminal OH groups

600 g / mol

PPG800

Polypropylene glycol without terminal OH groups

800 g / mol

EO-PO(50 / 50)2000

Without terminal OH group, made of epoxy

Ethane to Propylene Oxide in a 50:50 ratio

block copolymer

2000 g / mol

[0049] * Mw = average molecular weight

[0050] The polymers A listed in Table 2 were prepared in a known manner by polymer mimicking reactions of specific poly(me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com