Sewing machine

A sewing machine and process technology, which is applied in the field of sewing machines, can solve problems such as the inability to change the sequence, and achieve the effect of further rationalization and order realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] (The overall structure of the panel sewing sewing machine)

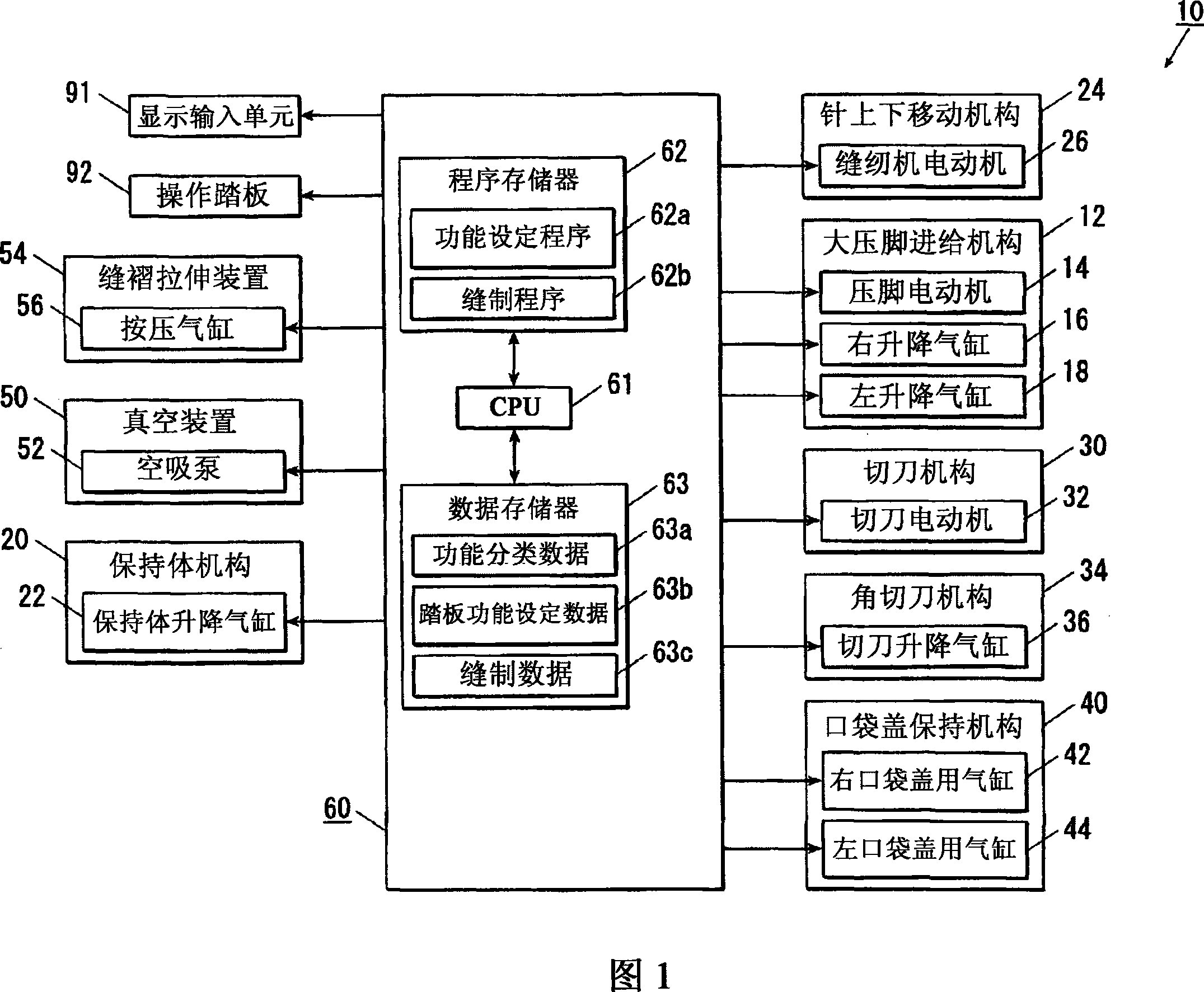

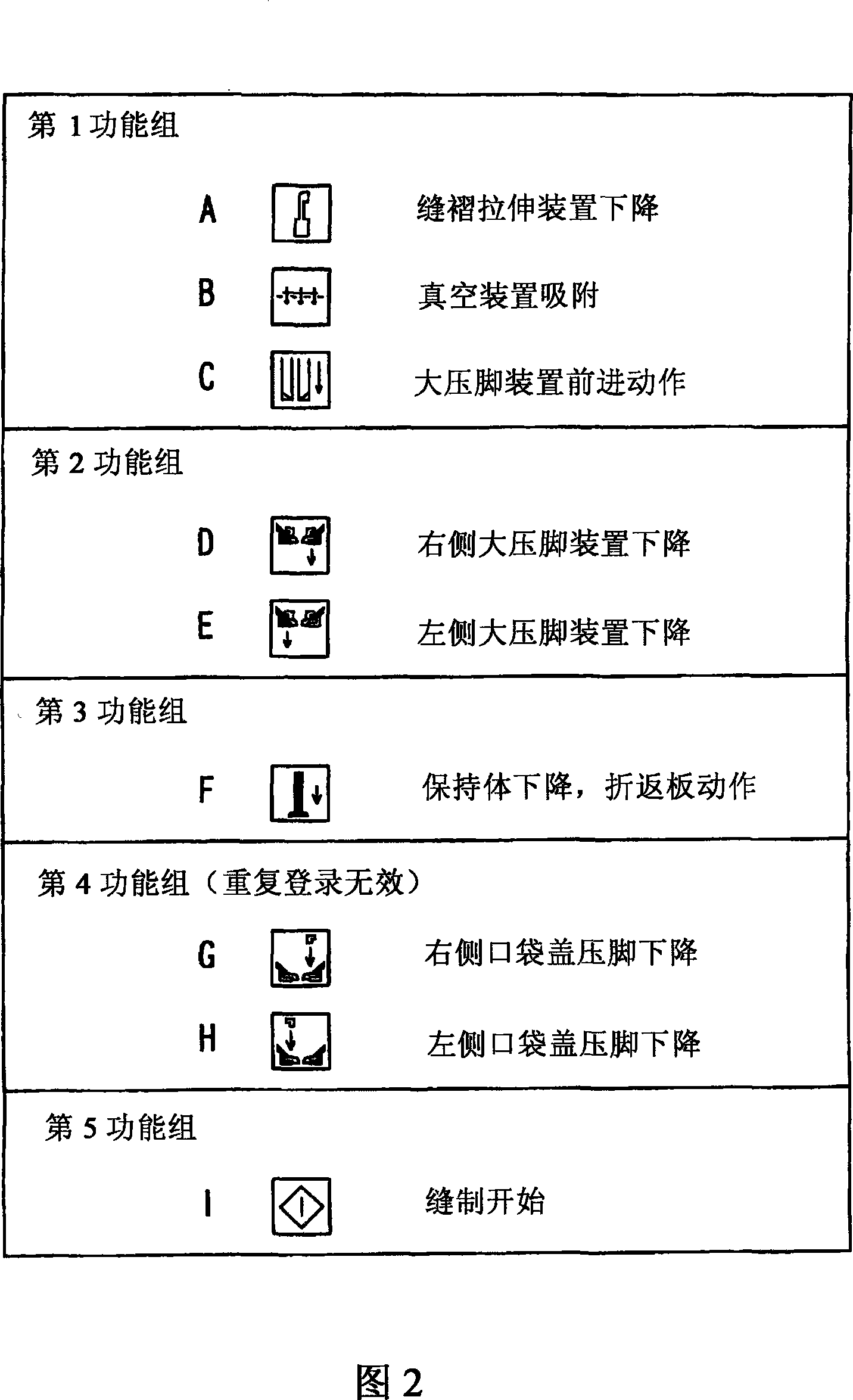

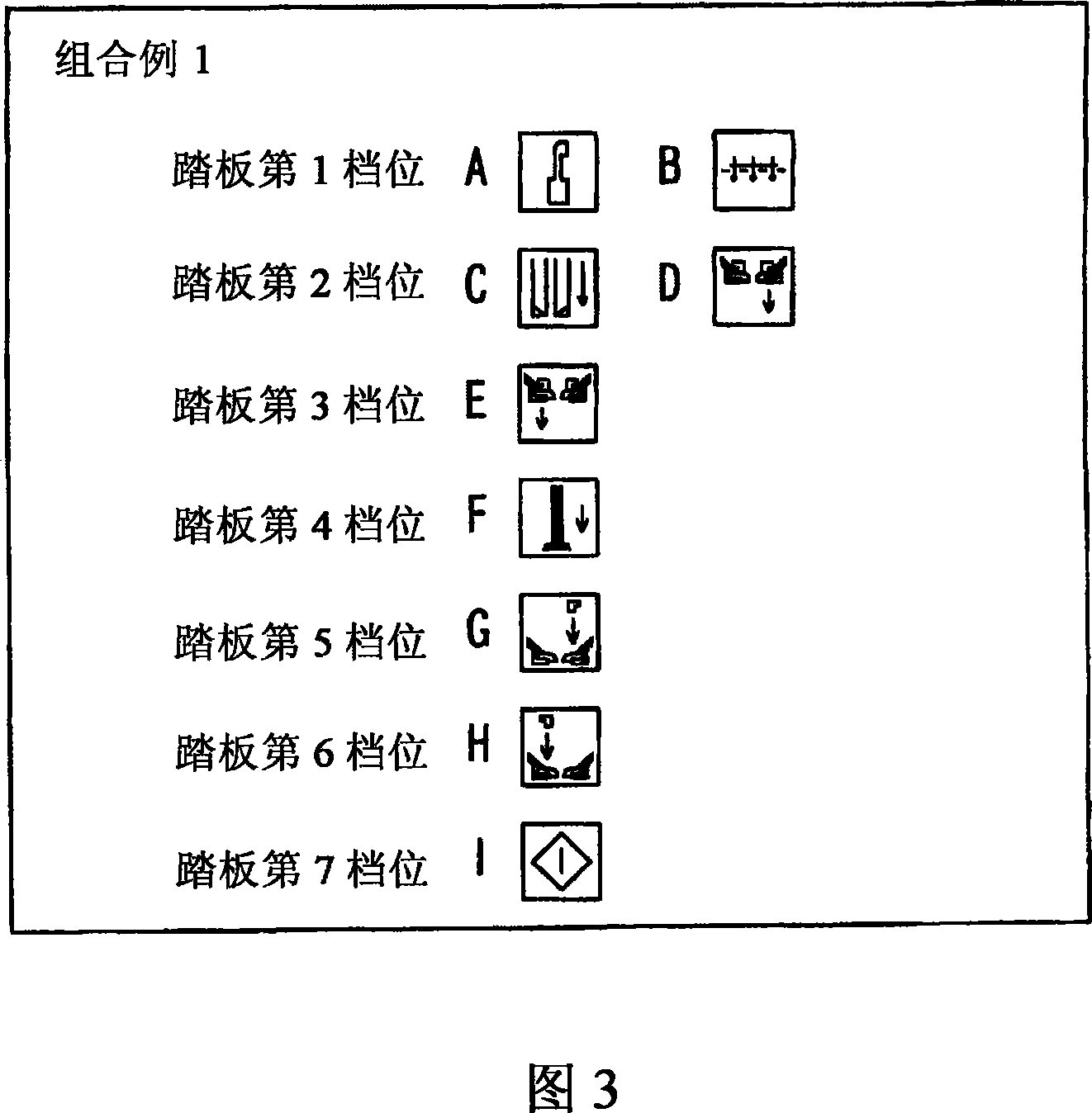

[0043] Next, a panel sewing sewing machine 10 as an embodiment of the present invention will be described based on FIGS. 1 to 23 . FIG. 1 is a block diagram showing an overall schematic configuration of a panel sewing sewing machine 10 .

[0044] The above-mentioned molding sewing sewing machine 10 forms two parallel stitches by stacking the molding cloth on the main fabric, and at the same time forms a linear slit between the stitches, and forms a V shape at both ends of the linear slit. Slit. In addition, when forming the stitches on one side, the pocket flap fabric is sewn. In addition, since the gathers are preliminarily formed on the main fabric, the folds are stretched so that no protrusions are formed due to the gathers during sewing.

[0045]The panel sewing sewing machine 10 has: a workbench (not shown) on which the main fabric and other sewing products are placed; a large presser foot feeding mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com