Circular expander for treating tubular fabric

A technology of tubular fabrics and expanders, applied in textiles and papermaking, fabric surface trimming, shaping/elongation of circular fabrics, etc., can solve problems such as instability and complex adjustment operations, and achieve the effect of avoiding permanent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

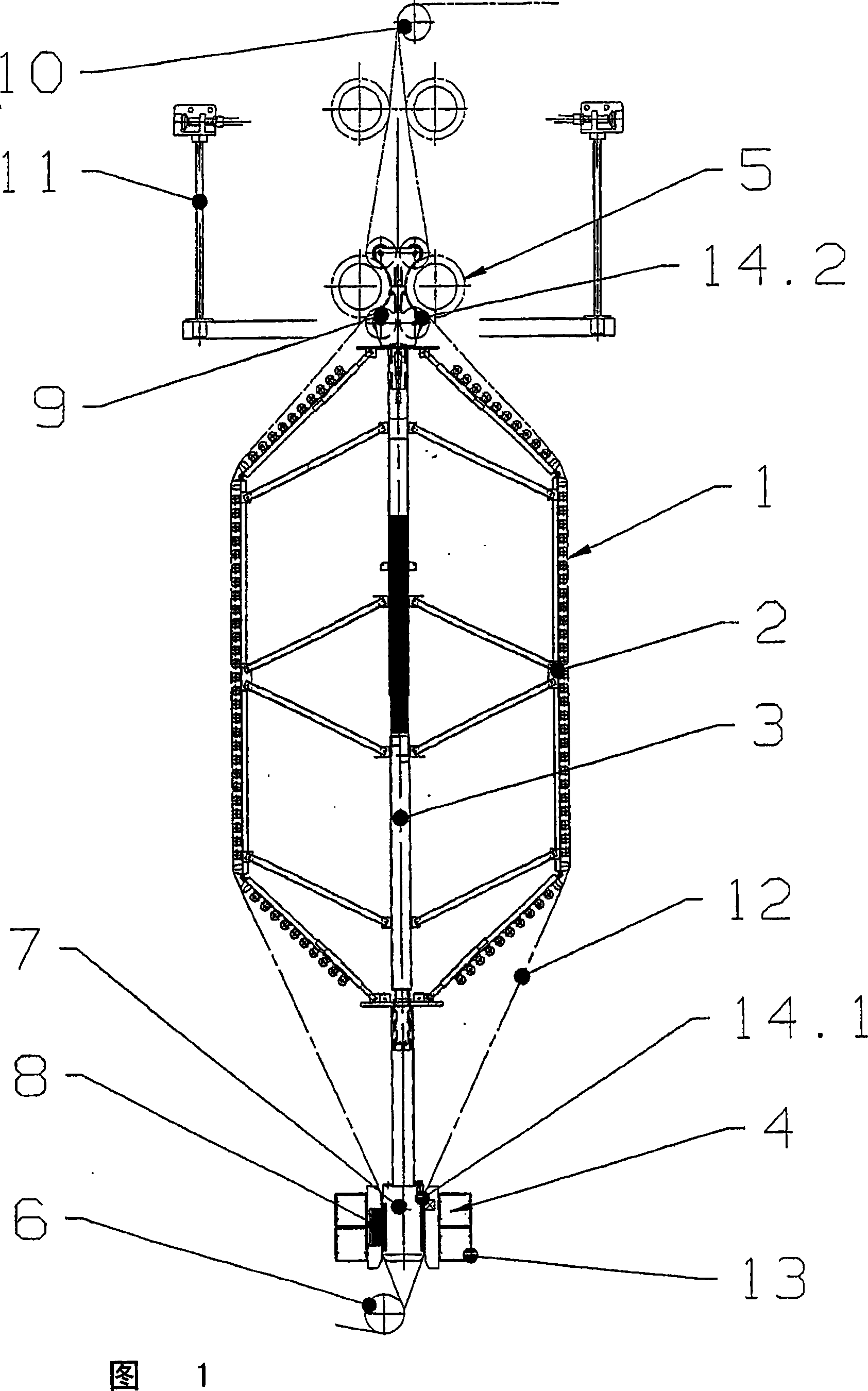

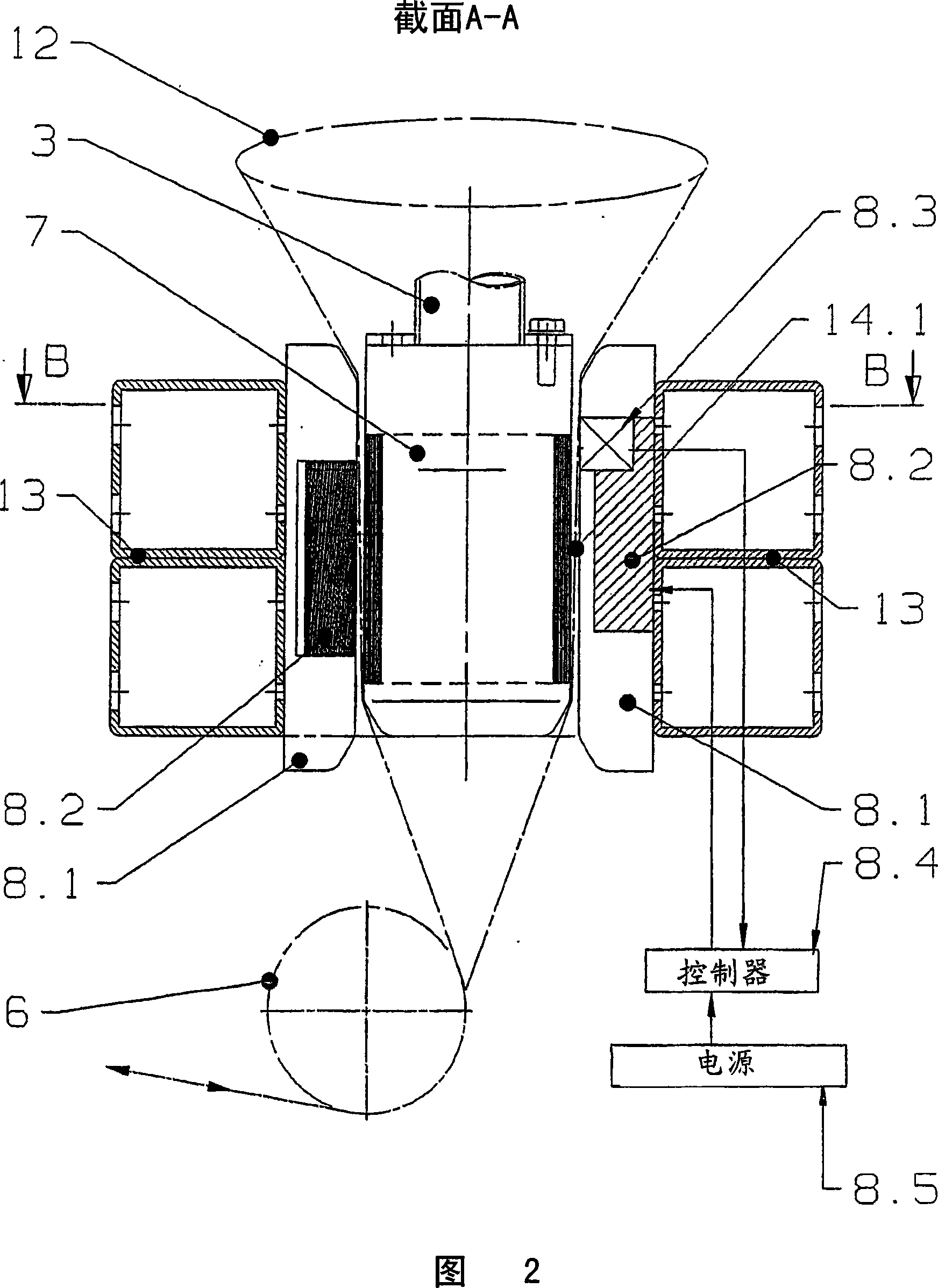

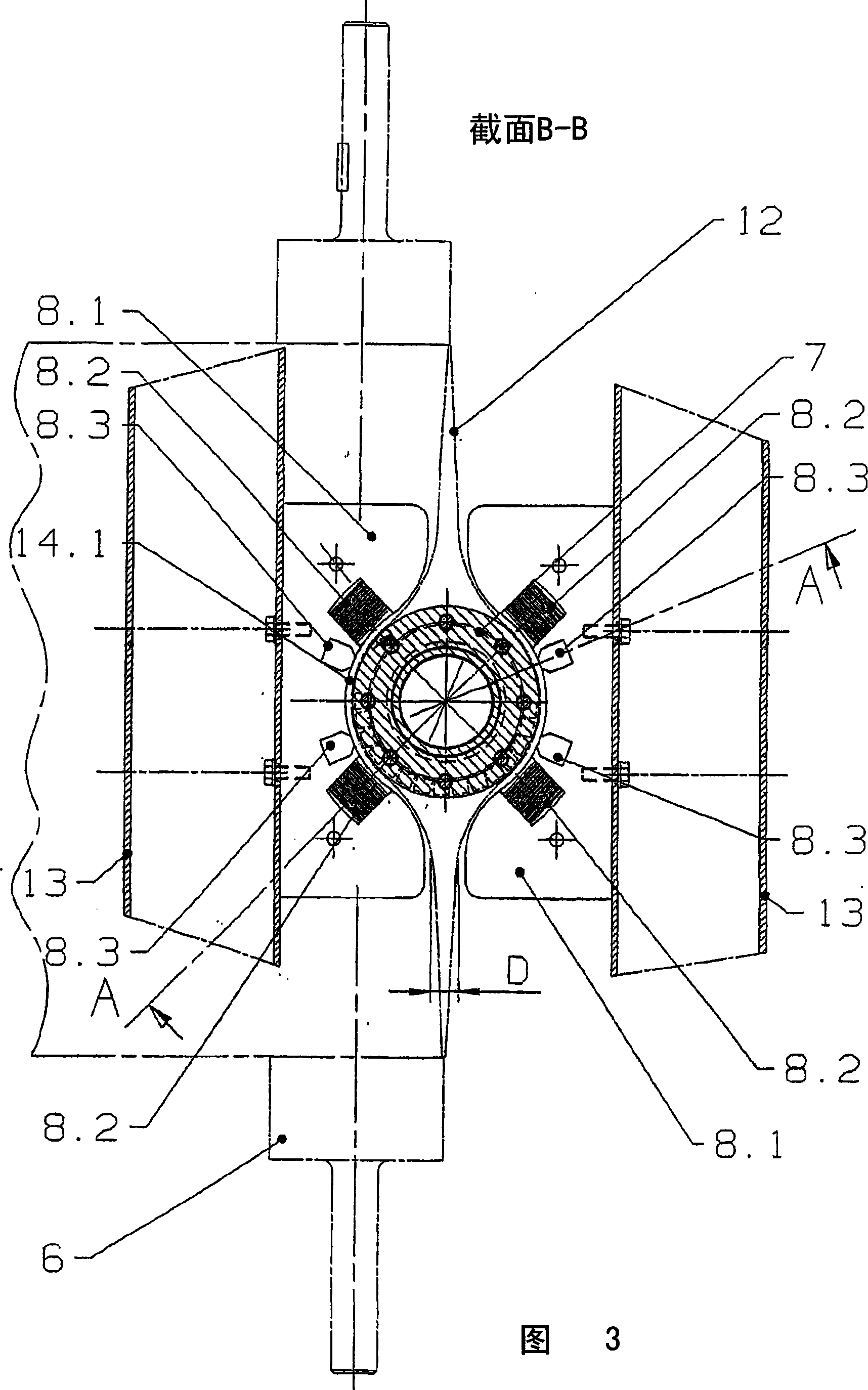

[0017] In FIG. 1 a circular expander unit 1 is shown which essentially comprises a vertically arranged circular expander 2 with a variable diameter which is passed through a telescopic central carrier 3 It is supported in the tubular fabric inlet 4 arranged below and in the tubular fabric outlet 5 arranged above. The tubular fabric 12 is supplied to the circular expander via a feed roll 6 arranged centrally below the circular expander unit 1 . The tubular fabric inlet 4 essentially consists of a centrally arranged rotationally symmetrical body 7 , which is rigidly connected to the lower end of the central carrier 3 , and an outer magnetic support 8 separated by a first fabric gap 14 .

[0018] The tubular fabric outlet 5 essentially consists of a roller bearing 9 known per se, consisting of pairs of support rollers and fixed rollers, between which the The circular expander forms a second fabric gap 14.2 through which the tubular fabric is guided. The tubular fabric 12 is spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com