New technique for forging bracket of back axle of automobile

A new technology, the rear axle technology, is applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., which can solve the problems of poor forging quality, high production cost, and difficulty in one-fire forging, etc. The effect of edge resistance, good forging quality and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

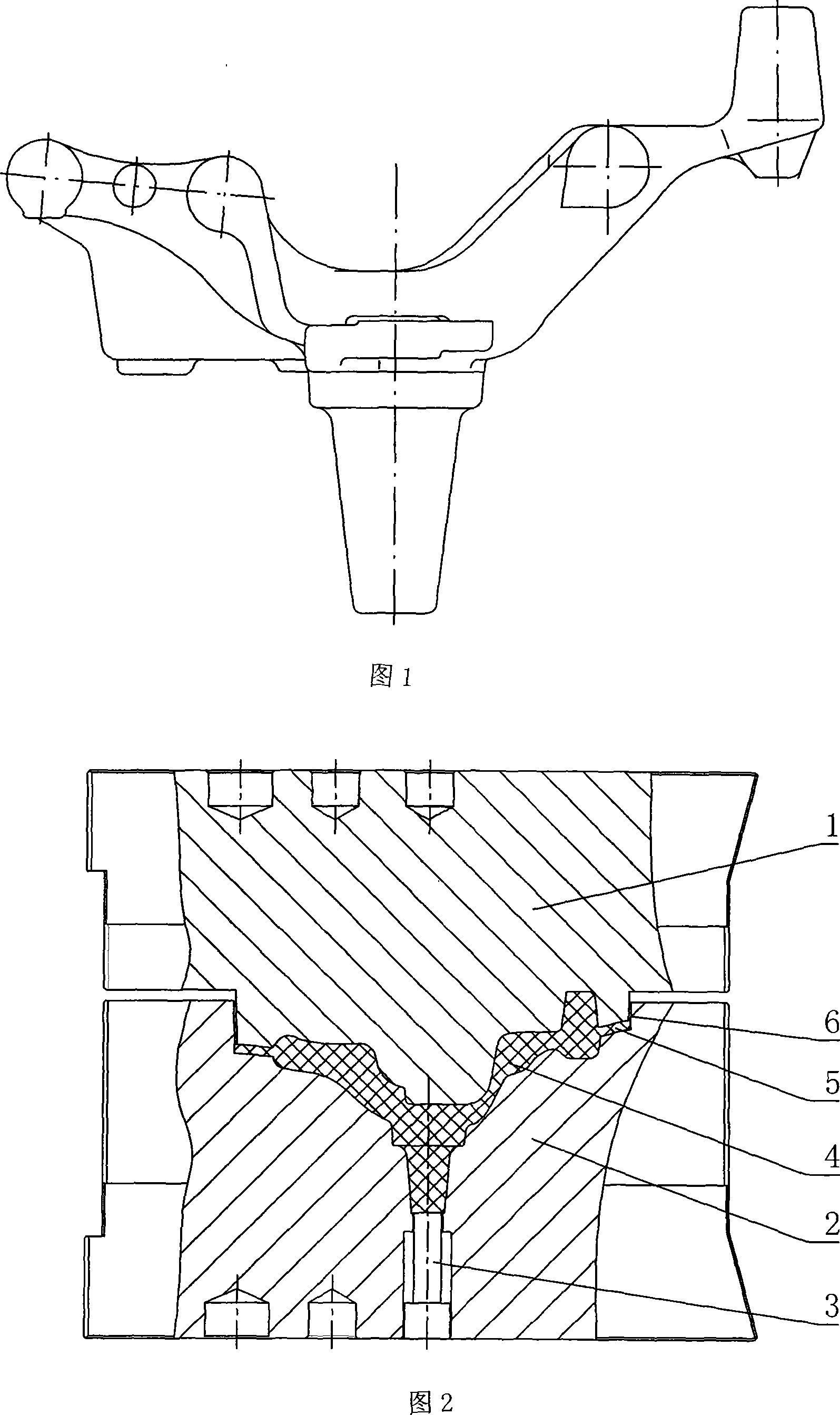

[0010] Figure 1 shows a cold forging diagram of an automobile rear axle bracket. The forging process is as follows: blanking - billet making (including two steps of gathering material and flattening) - pre-forging (closed flash closed die forging) - final forging (open die forging) - eager edge cutting - shaping. The process of billet making and final forging adopts the same process as that of conventional open forging. The billet making process adopts the commonly used billet making process design, including two steps of gathering and flattening. Material; the flattening step is to rotate the aggregated blank 90° along the axis to flatten both ends to obtain a preform. For the convenience of operation, the aggregate and flattening steps are usually arranged on a set of billet molds. Then pre-forge the pre-formed billet after the blank-making process. Pre-forging is the most critical process of the whole forging process. It adopts the closed-flash closed-type forging process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com