Building energy conservation composite wall connecting bridge

A compound wall and building energy-saving technology, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of unguaranteed construction quality, deformation of hollow composite walls, and slow construction speed, so as to achieve accurate geometric dimensions, The effect of fast construction and installation and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

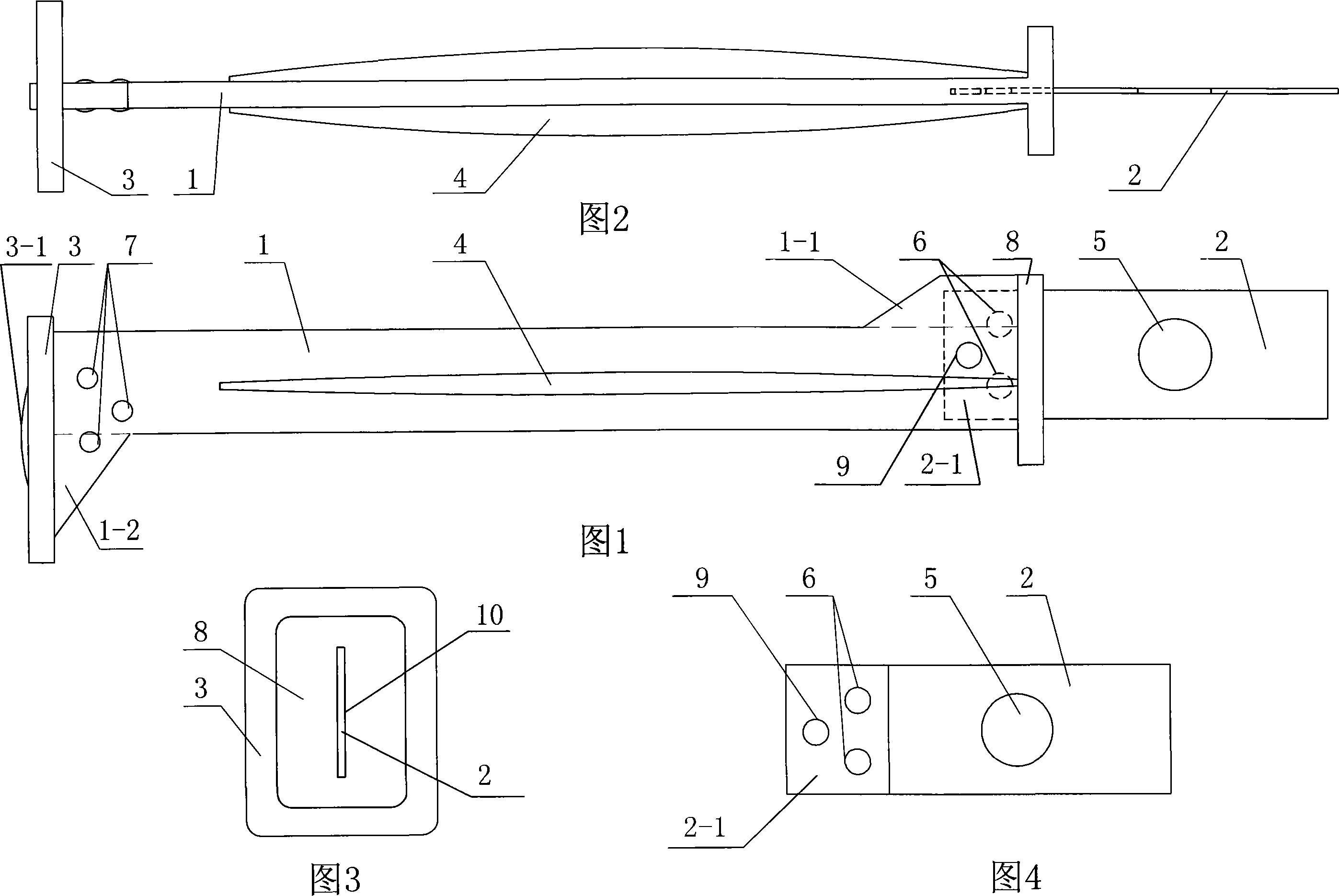

[0007] Specific Embodiment 1: As shown in Figure 1, Figure 2 and Figure 3, the building energy-saving composite wall connection bridge of this embodiment is composed of a connecting piece 1, a pull piece 2, and a plug-in plate 3; one end of the connecting piece 1 An end baffle 8 is provided, and the pull tab 2 is inserted into the vertical groove 10 provided on the connecting piece 1 and the end baffle 8 and fixedly connected with the connecting piece 1, and the inserting plate 3 is fixed on the other side of the connecting piece 1. On one end, reinforcing ribs 4 are provided on the front and rear sides of the connector 1 , and through holes 5 are provided on the pull tab 2 . When in use, the pull piece 2 is connected with the reserved hole on the side of the combined steel formwork with a steel mold clip, and the inserting plate 3 is inserted into the slot on the EPS insulation board.

specific Embodiment approach 2

[0008] Specific Embodiment 2: As shown in Figure 1, this embodiment also includes a first reinforcement strip 1-1, which is fixed to the upper end surface of the connector 1 and the left end surface of the pull piece 2 respectively. catch. With such a structure, the connection strength is improved. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific embodiment three: As shown in Figure 1, this embodiment also includes a second reinforcement strip 1-2, and the second reinforcement strip 1-2 is fixed to the lower end surface of the connector 1 and the right end surface of the plug-in plate 3 respectively. catch. With such a structure, the connection strength is improved. Other compositions and connections are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com