Free connecting parts of shear wall structure wall body

A technology for connectors and wall structures, which is applied to the connectors of formwork/formwork/work frame, the preparation of building components on site, and the construction of buildings, etc., which can solve the problem of unguaranteed construction speed and construction quality Cavity structure compound wall deformation, difficult to control the wall section size and other problems, to achieve the effect of reliable overall bending resistance, convenient construction, reliable anti-deformation rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

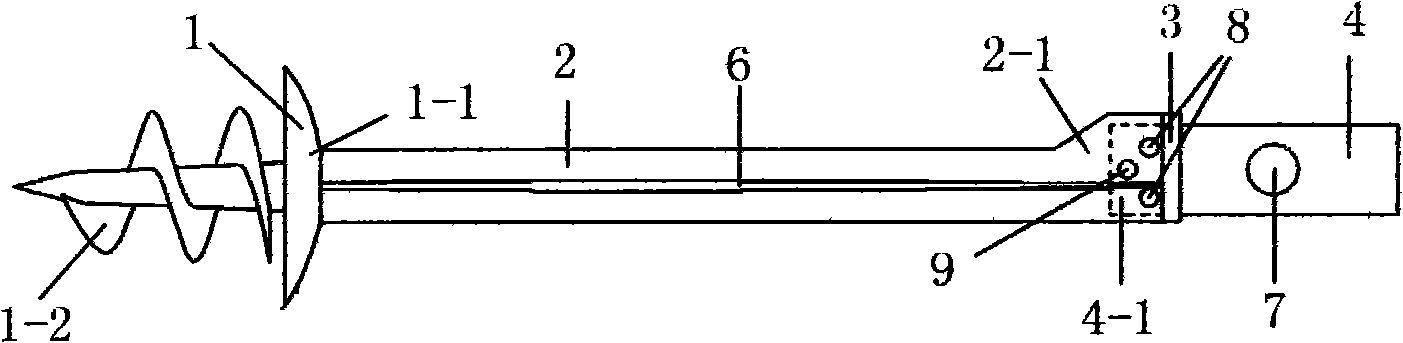

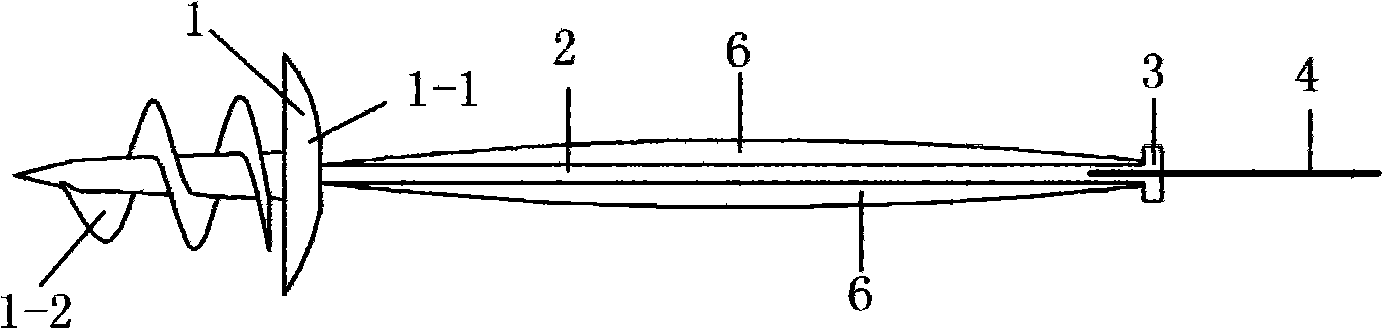

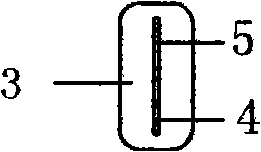

[0017] Specific implementation mode one: as figure 1 , figure 2 , image 3 , Figure 4 As shown, the building energy-saving composite wall free connector of the present embodiment is composed of a screw-shaped drill bit and an inter-top plate 1, a connecting rod 2, an end plate 3 and a pull piece 4; one end of the connecting rod 2 is provided with The drill bit and the mutual jacking plate 1 are provided with an end baffle plate 3 at the other end, and the pull piece 4 is inserted into the vertical groove 5 provided on the end baffle plate 3 and fixedly connected with the connecting rod 2, and the end baffle plate 3 is inserted It is fixed on the right end of the connecting rod 2 , the front and rear sides of the connecting rod 2 are provided with reinforcing ribs 6 , and the pull piece 4 is provided with through holes 7 . When in use, the pull piece 4 is connected with the reserved hole on the side of the combined steel formwork with a steel form clamp, and the drill bit ...

specific Embodiment approach 2

[0018] Specific implementation mode two: as figure 1 The illustrated embodiment also includes that the first reinforcing strip 2 - 1 is fixedly connected to the port of the connecting rod 2 and the left end surface of the pull piece 4 respectively. With such a structure, the connection strength is improved. Other composition and connecting rod relations are the same as the specific embodiment.

specific Embodiment approach 3

[0019] Specific implementation mode three: as figure 1 As shown, this embodiment also includes that the second reinforcing strip 1 - 1 is thin at the edge and thick at the root, and the second reinforcing strip is fixedly connected to the connecting rod 2 respectively. By adopting such a structure, the strength of the mutual top plate is improved. The other components and the relationship between the connecting rods are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com