Vane machine, in particular vane pump

A vane type and vane pump technology, which is applied in the direction of rotary piston machinery, mechanical equipment, rotary piston pumps, etc., can solve the problems of complicated and expensive manufacture of swing valve pumps, achieve good sealing, improve efficiency, and large delivery volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

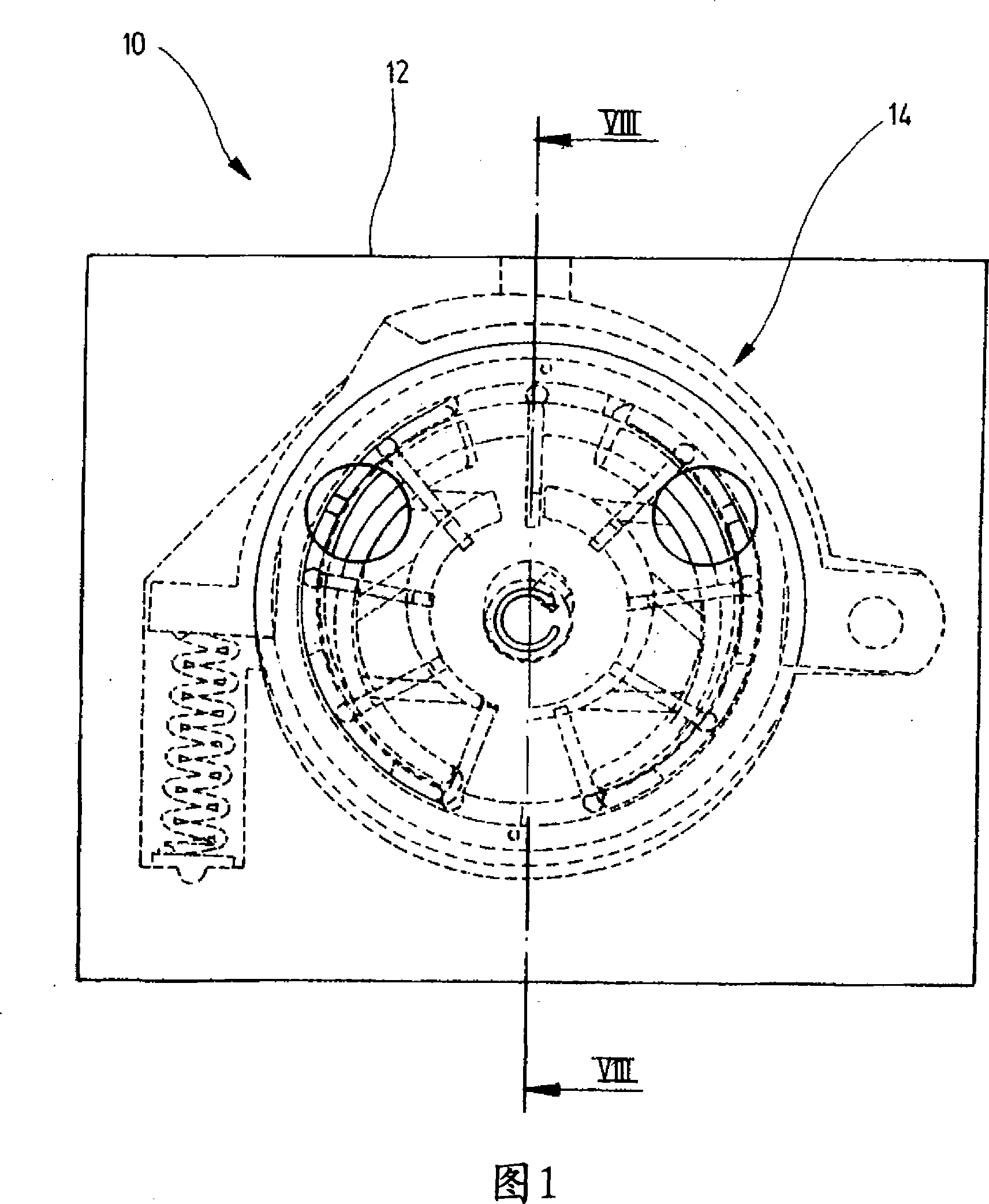

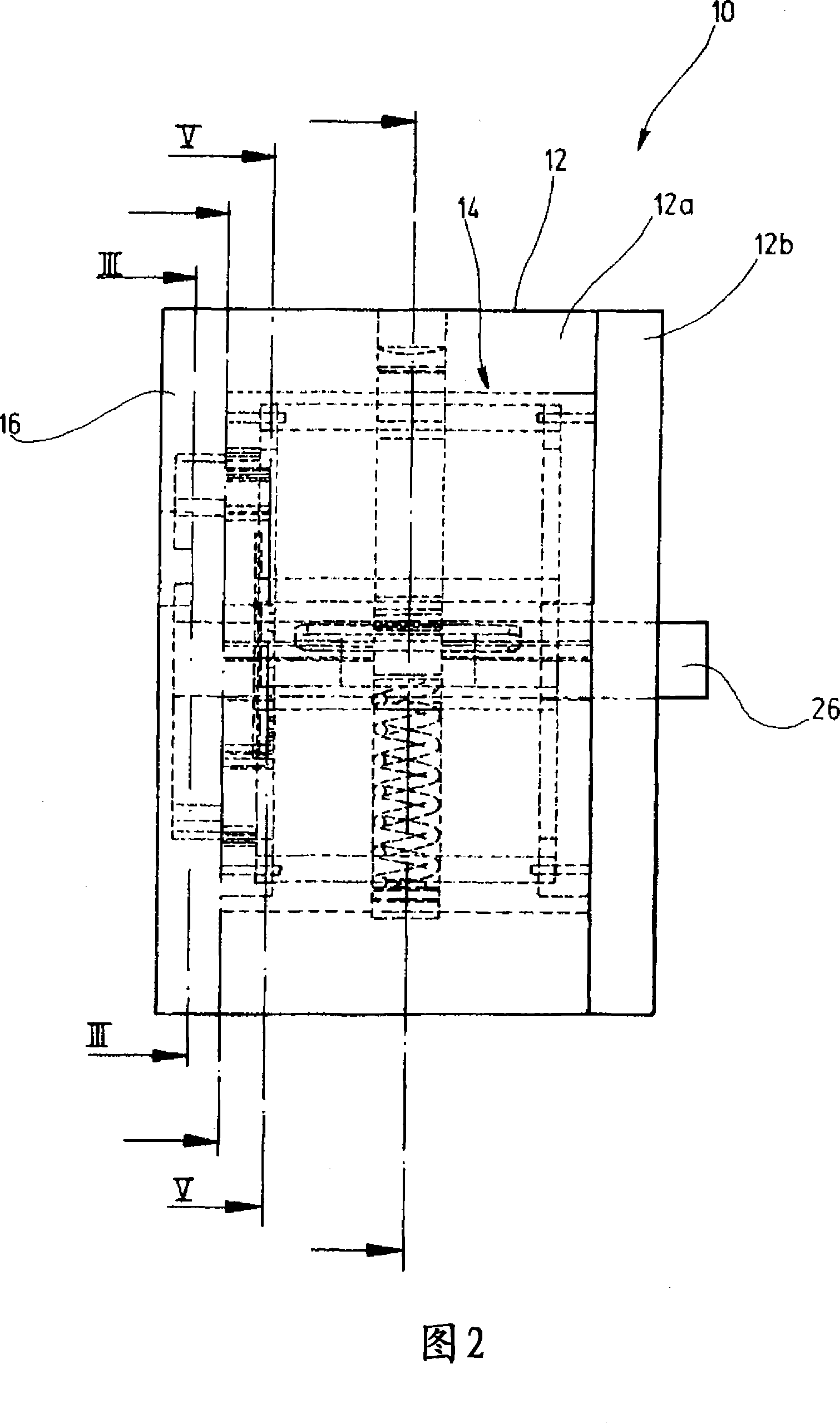

[0025] The vane pump has the reference numeral 10 as a whole in FIGS. 1-9 . It should be pointed out here that, for reasons of clarity, not all possible reference numerals are indicated in all subsequent figures. As shown in particular in FIG. 2, the vane pump includes a cylindrical housing 12 consisting of a pot-shaped part 12a and an end cover 12b. Disposed within the housing 12 is a pump assembly 14 .

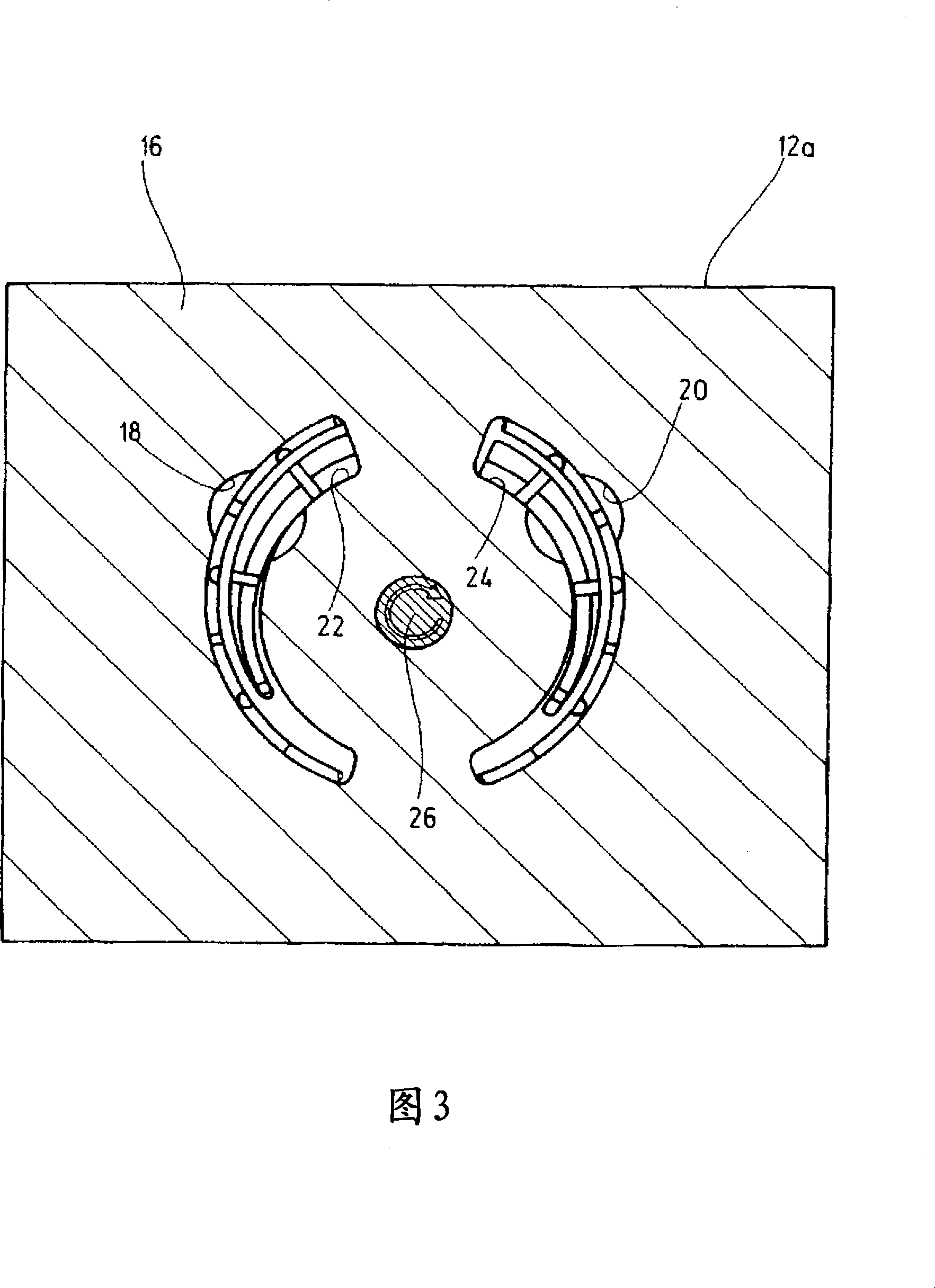

[0026] FIG. 3 shows a section III-III through a region of the base 16 of the pot-shaped section 12 a of the housing 12 from FIG. 2 . Inside this bottom 16 there is an inlet 18 and an outlet 20 which communicate with a kidney-shaped recess 22 or 24 present on the inside of the bottom 16 . Furthermore, a transmission shaft 26 is mounted on the base 16, which at its opposite end passes through the cover 12b of the housing 12 and can be connected there via a coupling not shown to a corresponding transmission.

[0027] As can be seen, for example, from FIGS. 6 and 7 , the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com