Light source drive circuit

A technology of light source driving circuit and dimming circuit, which is applied in the direction of light source, electric light source, electric lamp circuit layout, etc., can solve the problems of 107 breakdown of the dimming circuit, reducing product competitiveness, increasing the overall circuit volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

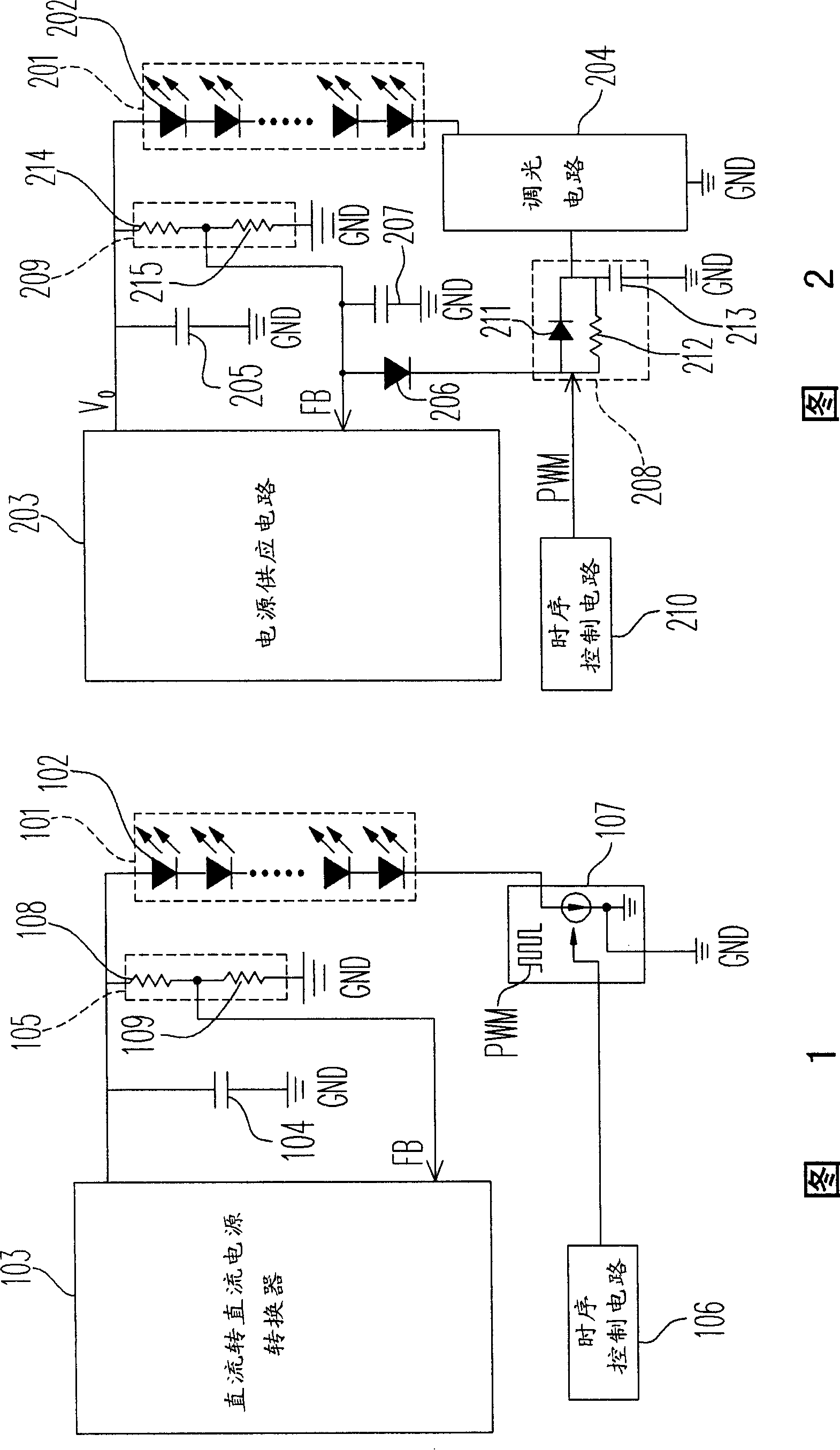

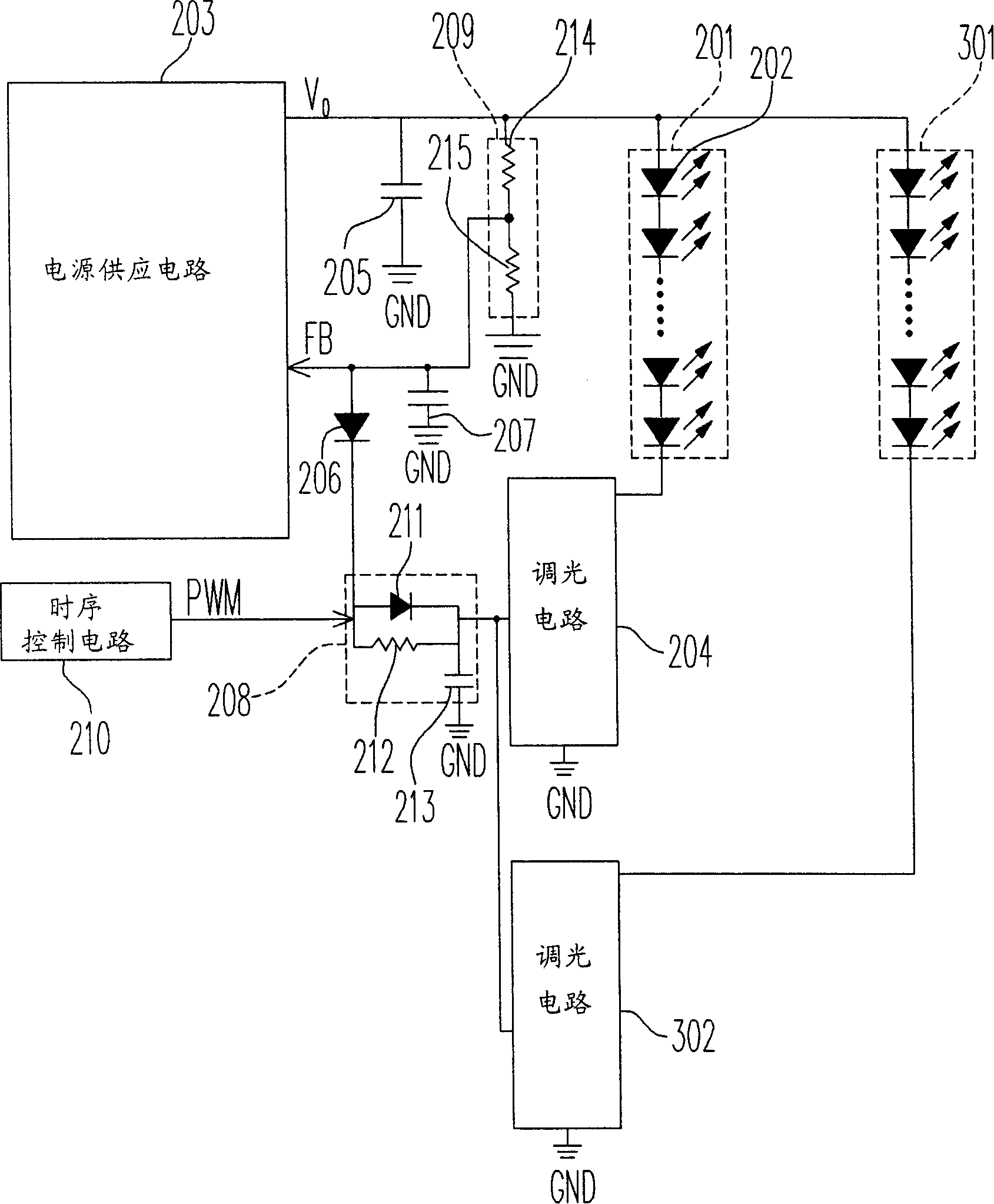

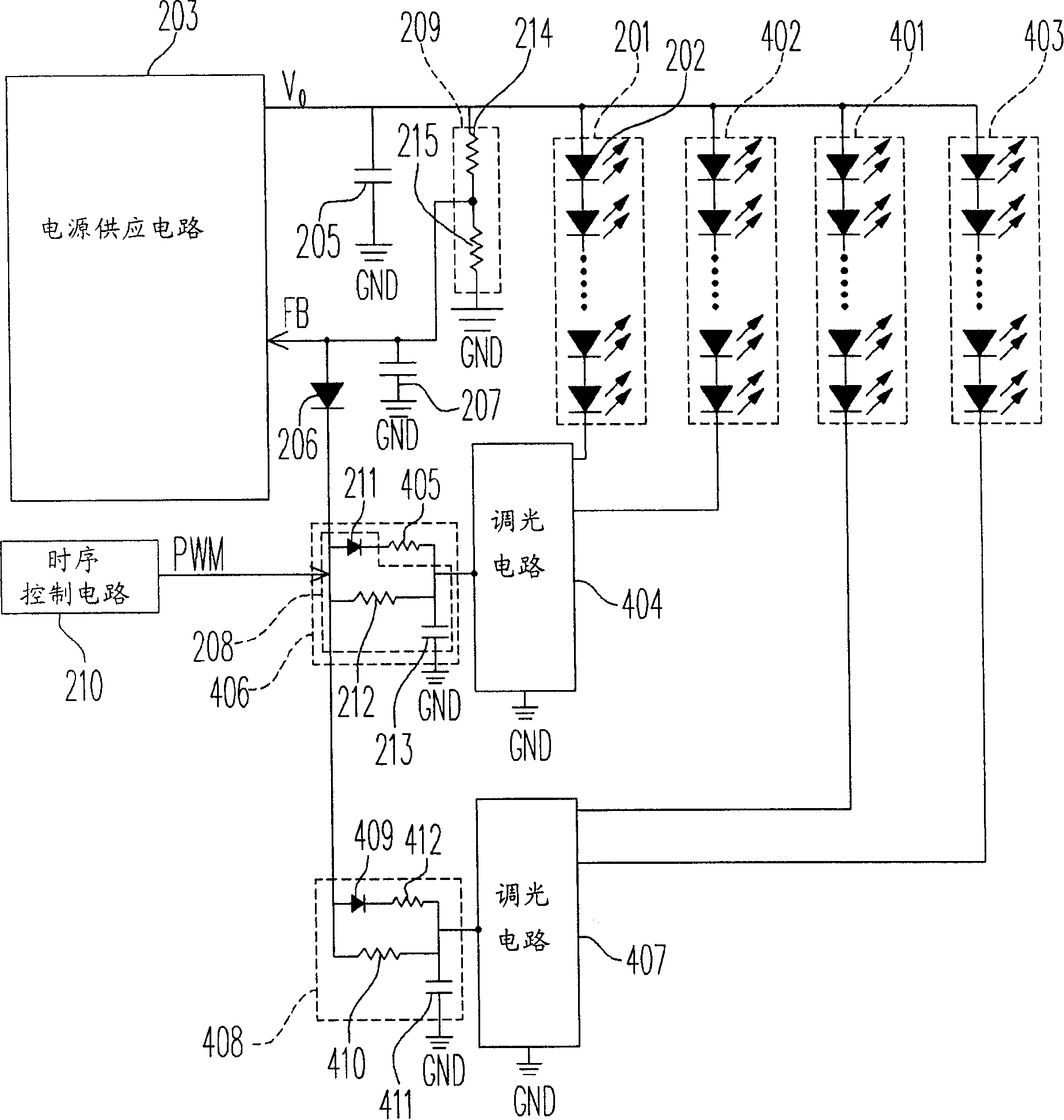

[0065] FIG. 2 is a circuit diagram of a light source driving circuit according to an embodiment of the invention. Please refer to FIG. 2 , the light source driving circuit is used to drive the first light emitting element 201 . The first light-emitting element 201 may be a light-emitting diode, as shown in 202 in FIG. 2 , or may be a light-emitting diode string formed by connecting a plurality of light-emitting diodes 202 in series, or other types of light-emitting elements / light-emitting element strings. The light source driving circuit includes a power supply circuit 203, a first dimming circuit 204, a capacitor 205, and a feedback circuit.

[0066] The power supply circuit 203 has an output terminal and a feedback terminal, and the output terminal is coupled to one end of the first light-emitting element 201 for supplying the power supply voltage Vo to the first light-emitting element 201, and the power supply circuit 203 is configured according to the feedback terminal. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com