Method and device for transferring a pattern from a stamp to a substrate

A technology of stamp and substrate, which is applied in the field of transferring patterns from stamp to substrate and device, can solve the problems of deformation of transfer pattern and unsatisfactory device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

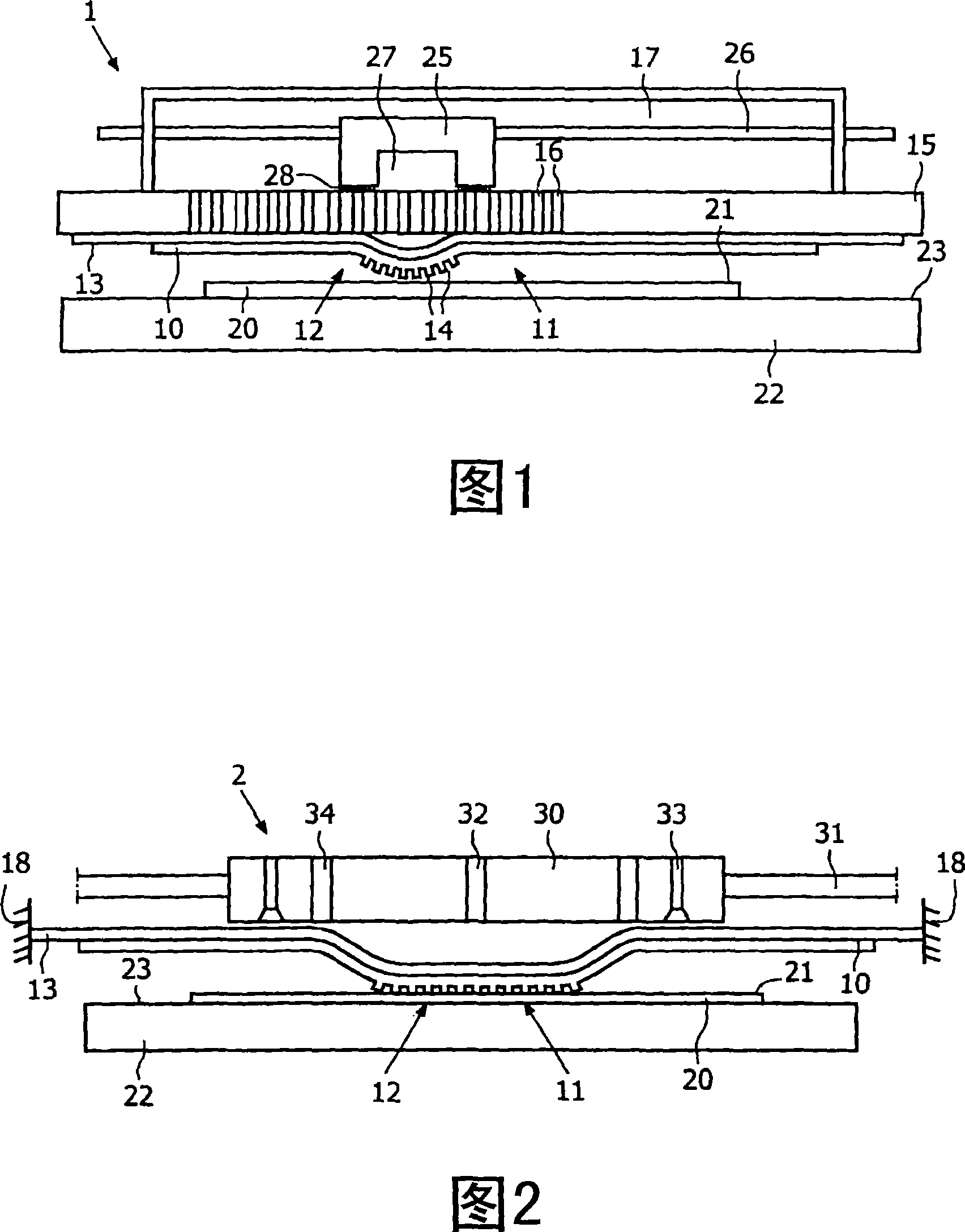

[0029] FIG. 1 schematically shows a device according to a first embodiment, denoted by the reference symbol 1 . This device 1 is referred to as a first pattern transfer device 1 below.

[0030] The first pattern transfer device 1 is used to transfer the pattern 12 from the embossing surface 11 of the stamp 10 to the receiving surface 21 of the substrate 20 . To support the substrate 20 , the first pattern transfer device 1 comprises a table 22 with a support surface 23 . The base body 20 is fixed on a stage 22 by a suitable fixing mechanism (not shown). For example, the table 22 can be designed as a vacuum chuck, which holds the base body 20 on the support surface 23 by means of a vacuum.

[0031] The stamp 10 is made of a flexible material so that it is very easy to deform the stamp 10 . For example, the material of the stamp 10 is chosen such that local deformations already occur when a small portion of the stamp 10 is subjected to a very slight overpressure of only 1 kPa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com