Support bearing assembly

一种轴承组件、支撑件的技术,应用在轴承、轴和轴承、滚动接触轴承等方向,能够解决任何用户不合适、军事用户存在潜在危险、天线杆损害等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

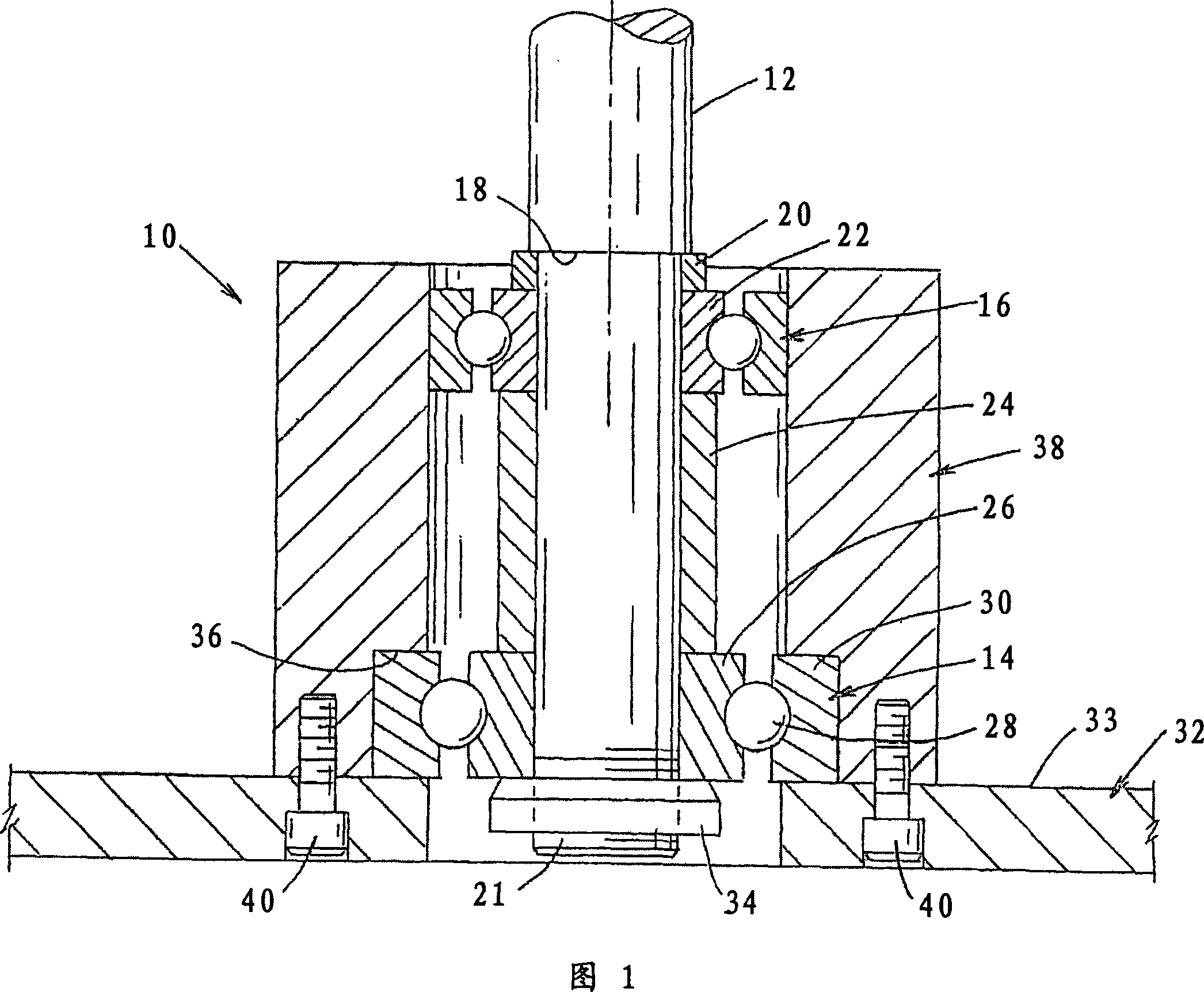

[0029] Referring to FIG. 1 , a prior art rigid bearing assembly 10 around an axis of rotation 12 is shown. The axis of rotation is shown as an axial drive screw of a screw driven telescoping antenna mast assembly, but is not limited thereto. A bearing assembly allows the shaft to rotate freely. Bearings 14 and 16 are positioned axially along the length of the shaft to provide lateral support to the rotating shaft. The axial spacing of the bearings provides moment resistance against tipping of the shaft. Vertical support in the downward direction is provided by the lower shoulder 18 of the shaft which will force through the washer 20, the inner race 22 of the upper bearing 16, the bushing 24, the inner race 26 of the lower bearing 14, the lower The ball bearings 28 of the bearings, and the outer ring 30 of the lower bearing 14 are transferred to the upper surface 33 of the base 32 . Vertical support in the upward direction is provided by lifting the shaft on a lock nut or "h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com