Windshield wiper system for vehicles, especially motor vehicles

A wiper, motor vehicle technology, applied in the direction of vehicle cleaning, vehicle maintenance, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

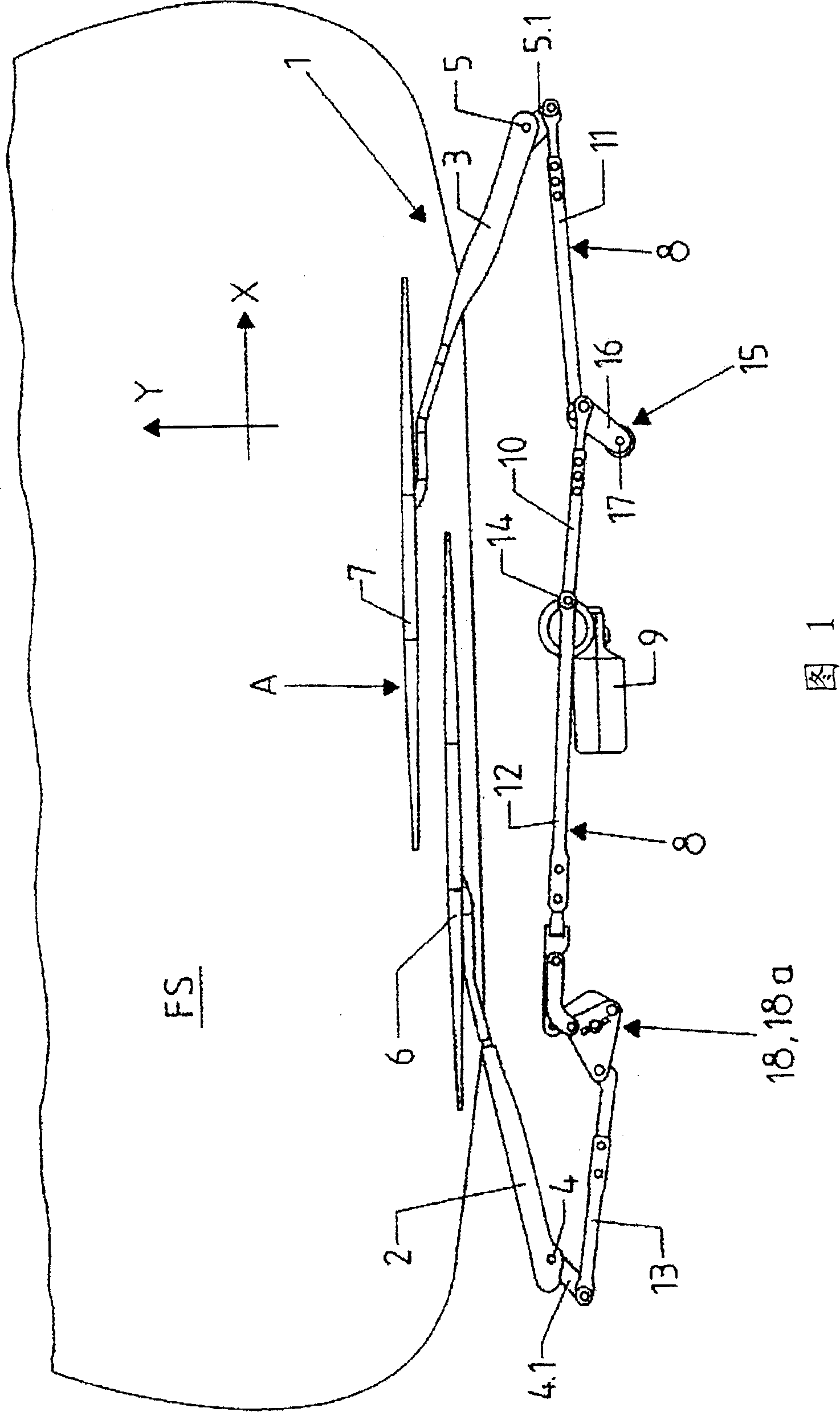

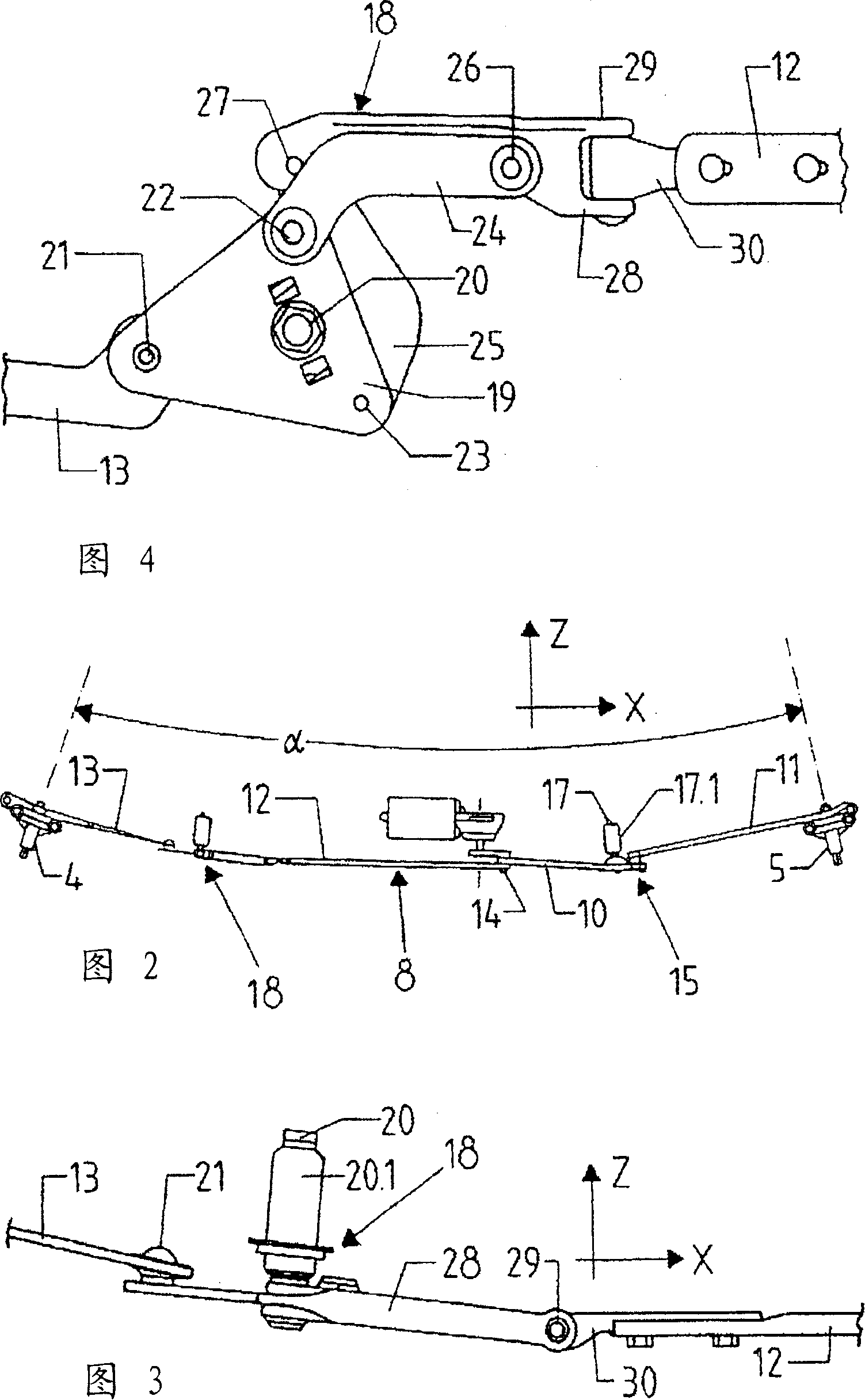

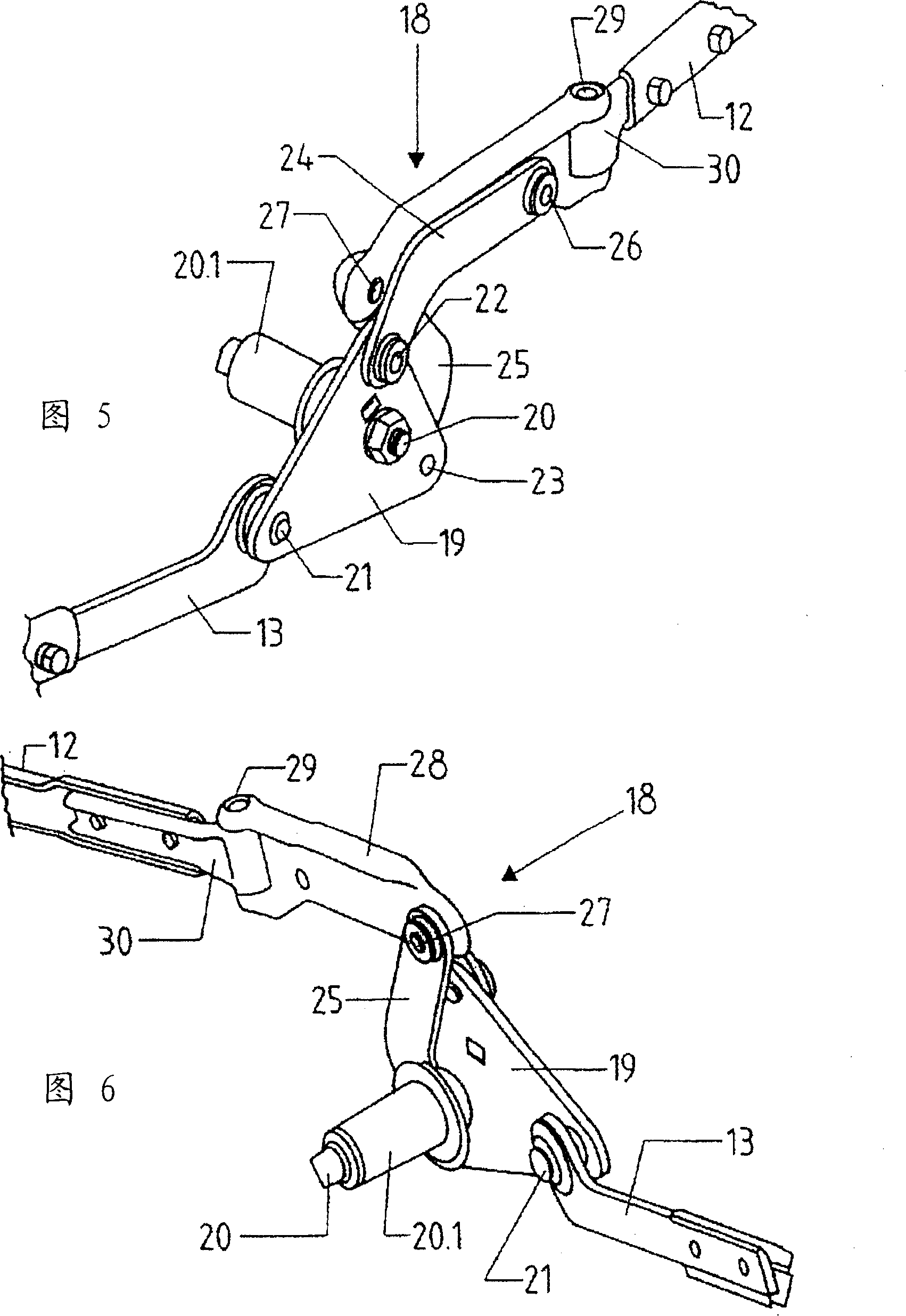

[0046] To simplify the explanation, the spatial axes run perpendicularly to each other, i.e. the X-axis, Y-axis and Z-axis are shown in Figures 1-3, and the X-axis and Y-axis are in the drawing plane of Figure 1, i.e. they define the The drawing plane, while the X-axis and Z-axis are in the drawing plane of FIGS. 2 and 3 and are defined by XZ coordinates.

[0047] The windscreen wiper unit normally operates in reverse motion as shown at 1 in the accompanying drawings, the windscreen wiper unit mainly comprises two wiper arms 2 and 3, one end of which is connected to the wiper shafts 4 and 5 respectively, And the other end of the arm carries the wiper blades 6 and 7 which are placed against the vehicle windscreen WS.

[0048] In Figures 1 and 2 the vehicle windshield is wiped and cleaned by means of a drive train generally indicated by 8 and by crank arms 4.1 and 5.1 arranged on and projecting radially from wiper shafts 4 and 5 The two wiper arms 2 and 3 can pivot opposite eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com