Screw device and method of manufacturing the same

A screw and nut technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of small elastic deformation of the roller, easy to lengthen the nut, difficult preload management, etc. The effect of shortening the length in the axis direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

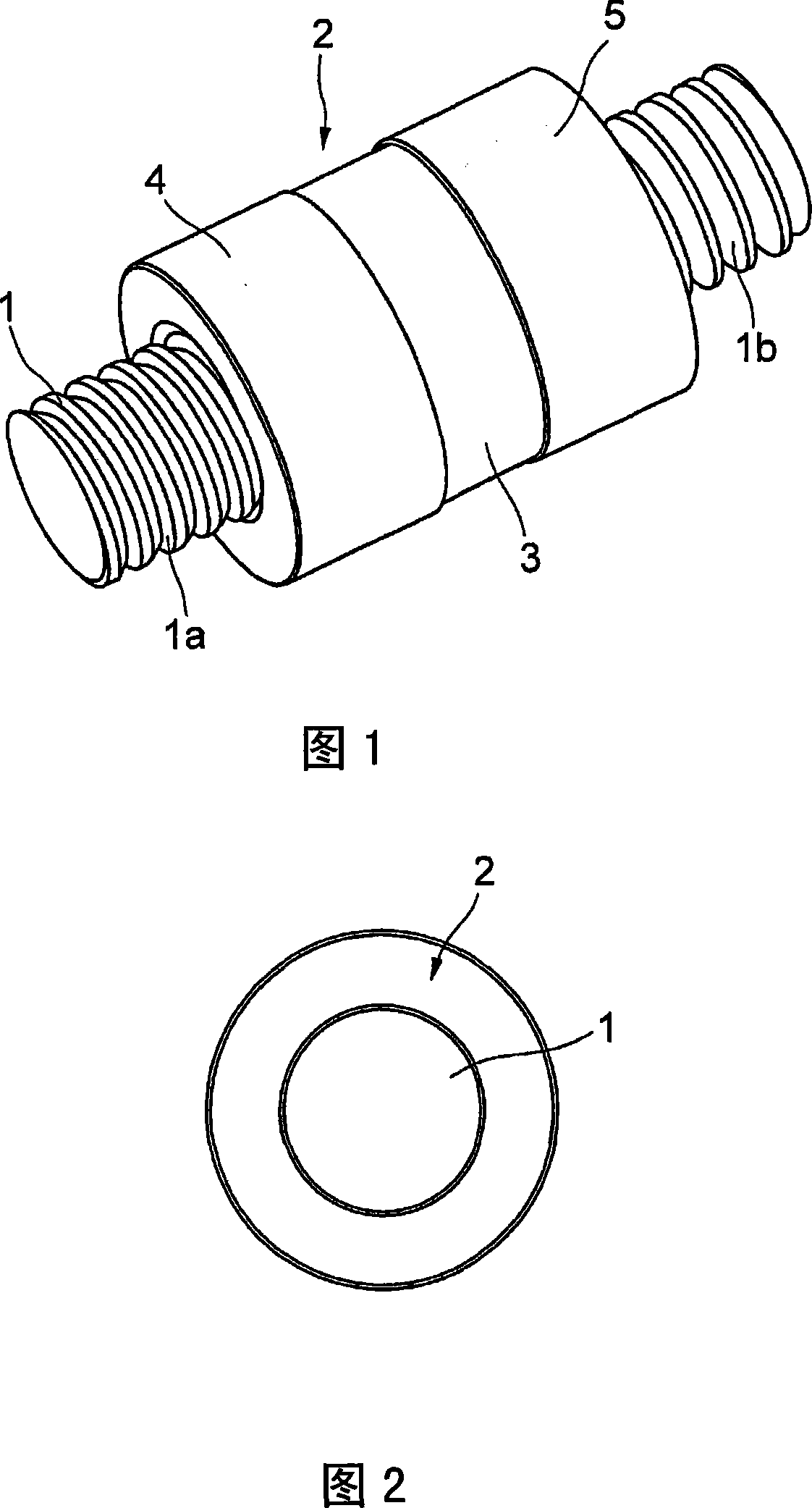

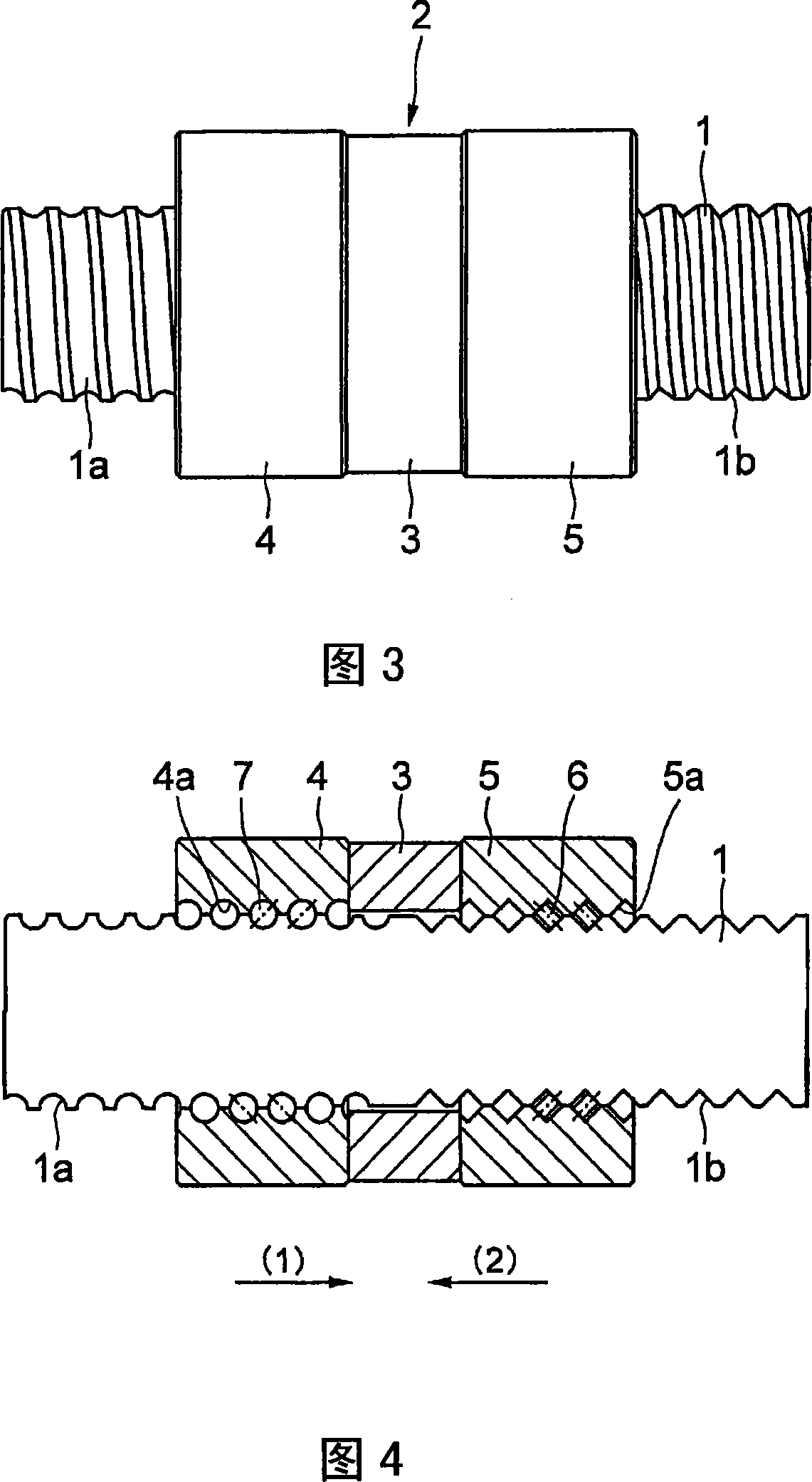

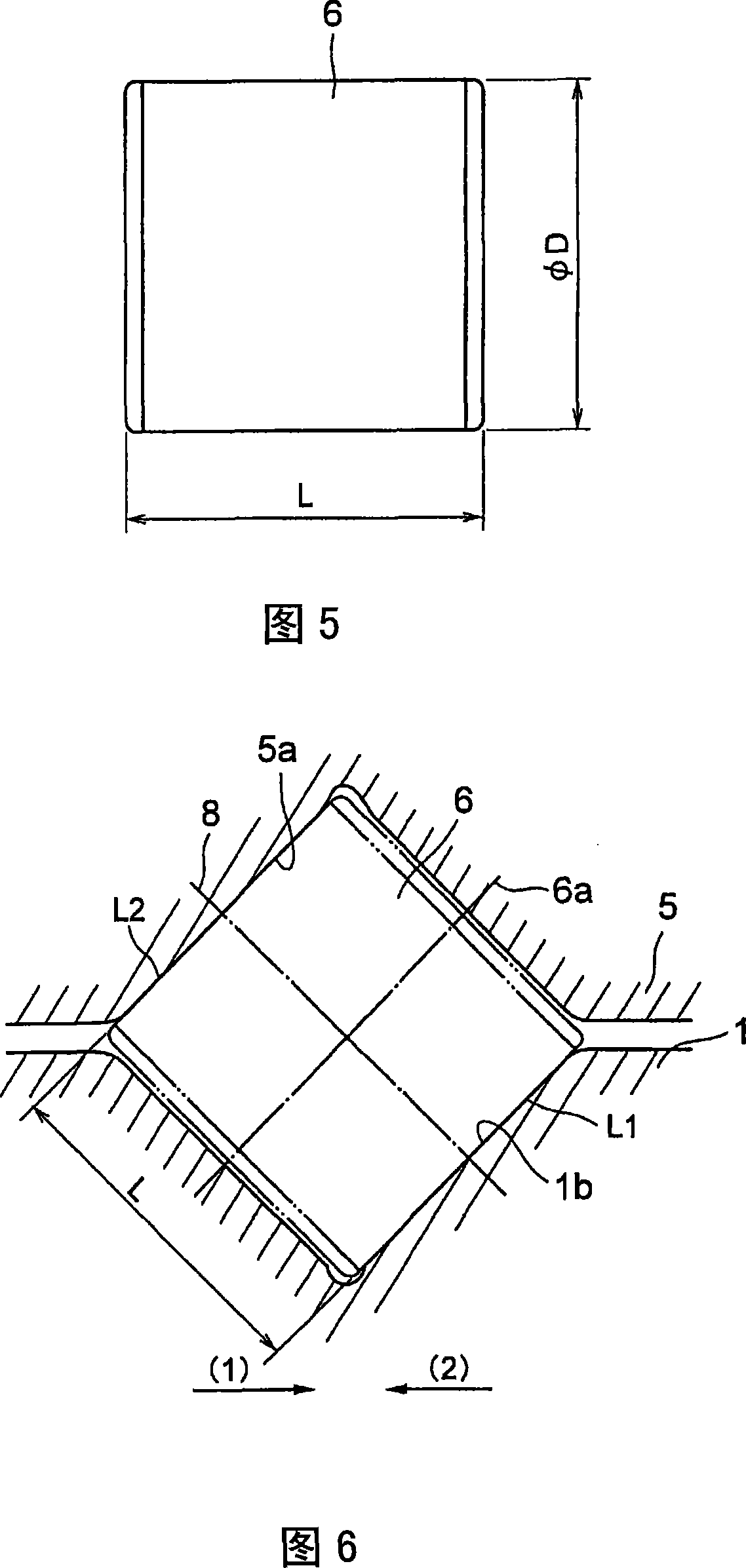

[0032]Hereinafter, the present invention will be described in detail with reference to the drawings. 1 to 3 show a screw device according to a first embodiment of the present invention. 1 shows a perspective view of the screw device, FIG. 2 shows a front view, and FIG. 3 shows a side view, respectively. In Figures 1 to 3, symbol 1 is a threaded shaft, and symbol 2 is a connecting nut. The connecting nut 2 is composed of a ball nut 4 and a roller nut 5 connected via a washer 3 .

[0033] The threaded shaft 1 is formed with both a helical ball rolling groove 1a in which the balls roll and a roller rolling groove 1b in which the rollers roll. The threaded shaft 1 is divided into a ball rolling groove region in which only the ball rolling groove 1a is formed and a roller rolling groove region in which only the roller rolling groove 1b is formed along its axial direction.

[0034] The ball nut 4 of the connection nut 2 faces the ball rolling groove 1 a of the threaded shaft 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com