Coupling piece for a detachable connection of containers

A technology of coupling elements and disassembly connections, applied in the field of coupling elements, can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

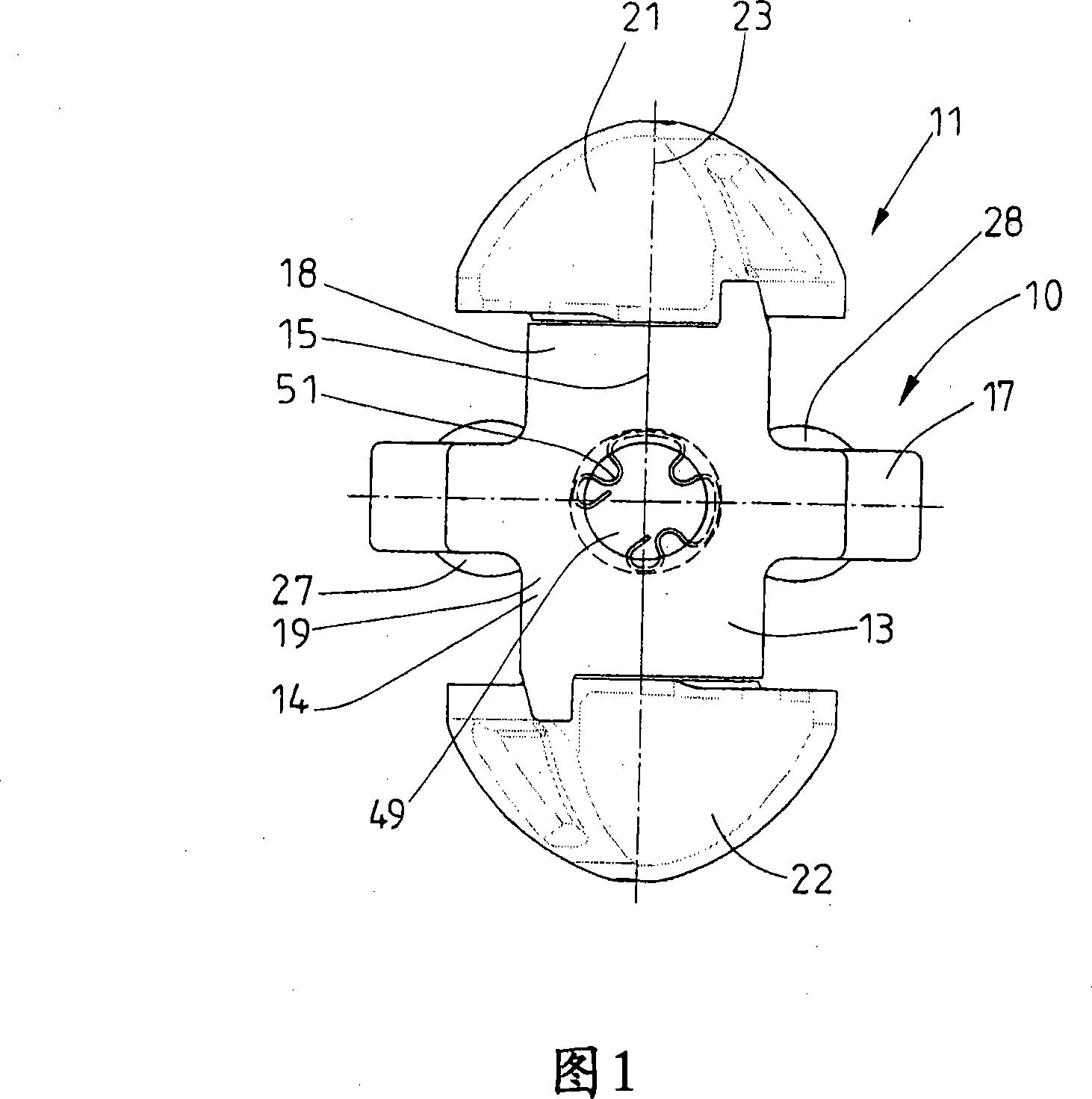

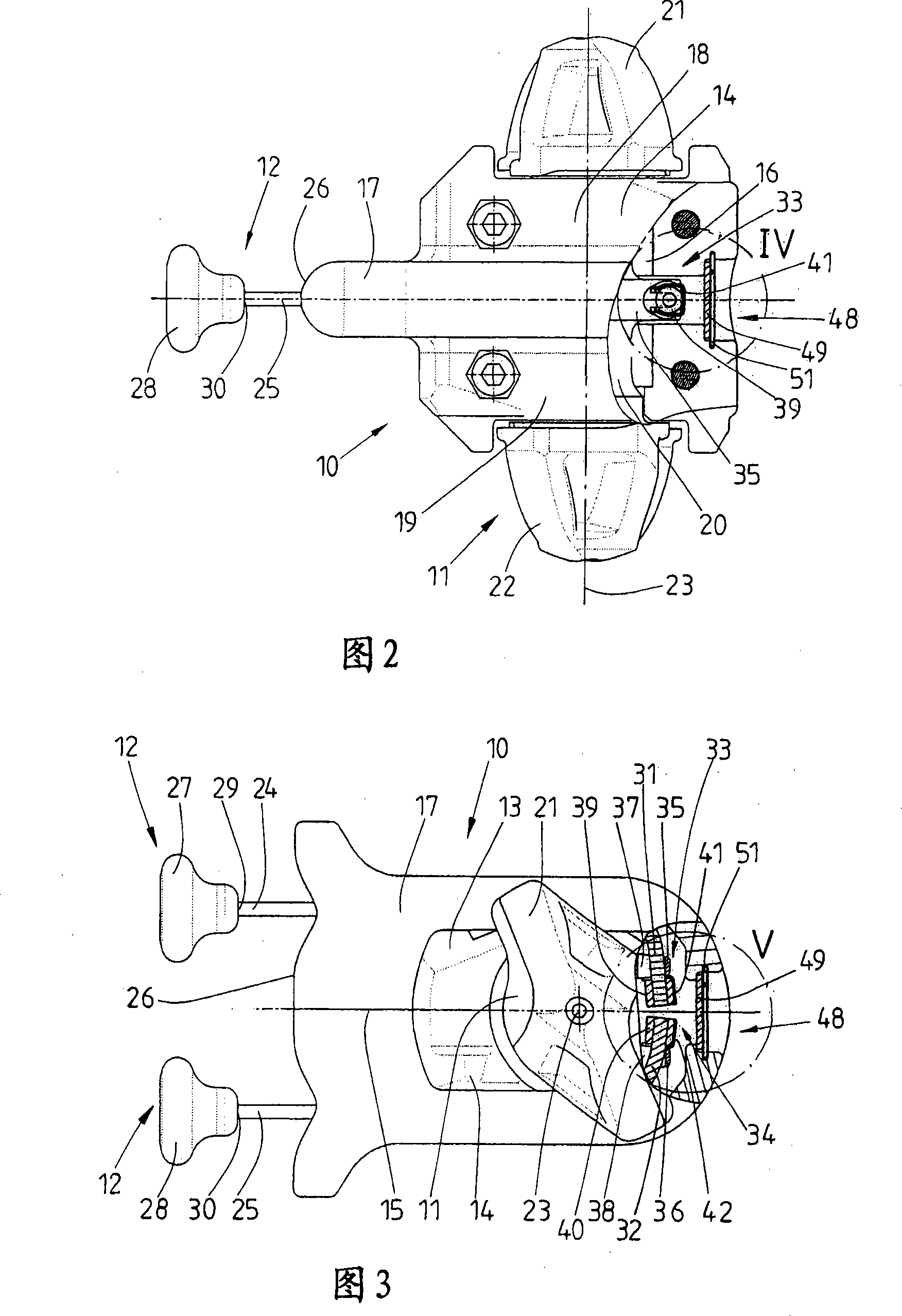

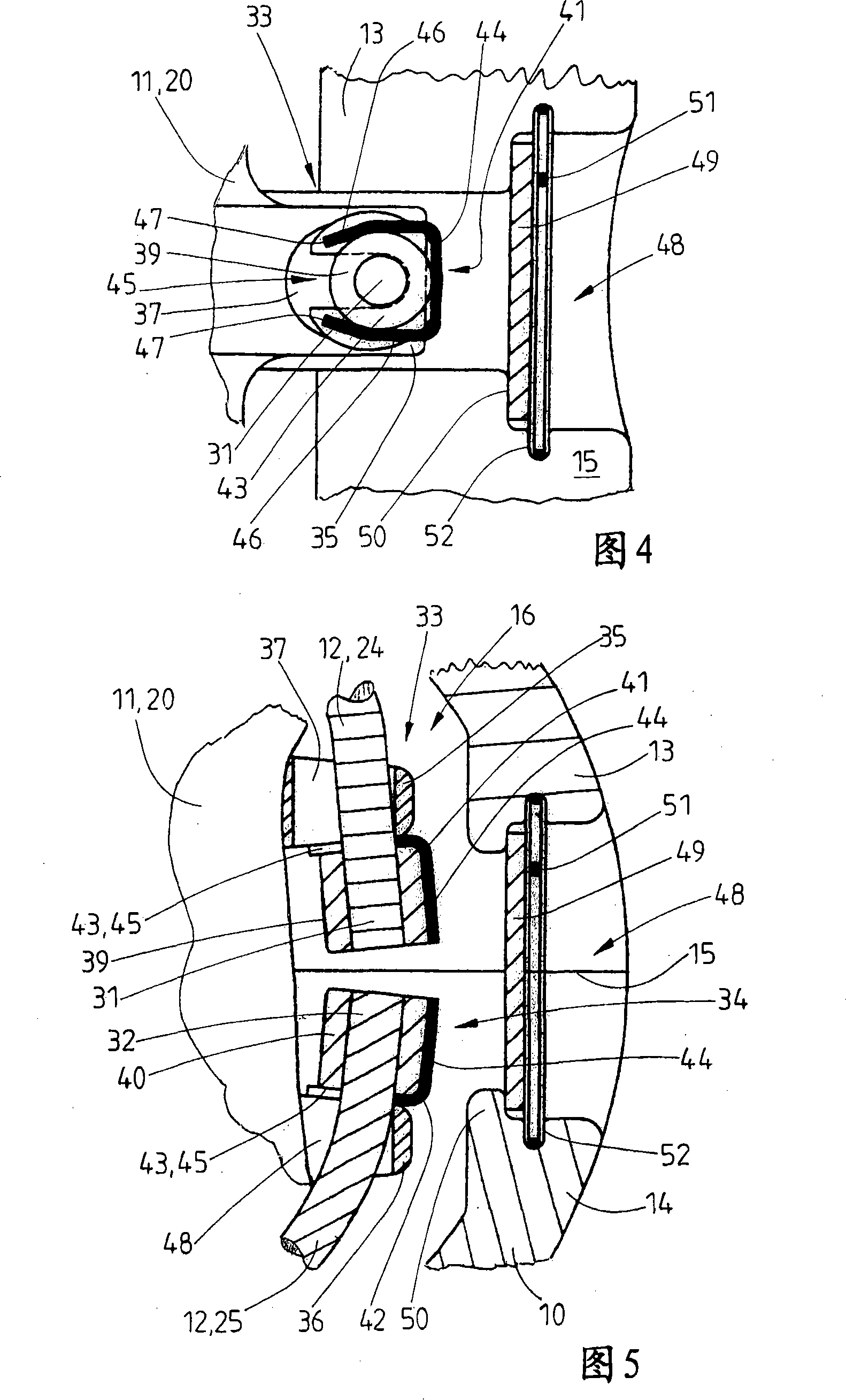

[0023] Two embodiments of coupling elements shown are so-called semi-automatic twist locks for the semi-automatic connection of vertically stacked containers (not shown in the figures). The coupling element locks automatically as soon as the containers to be connected are positioned in a stack. Only manual unlocking of the coupling element is required.

[0024] Figures 1 to 5 show a semi-automatic coupling element consisting of the following necessary parts: a chamber 10, a locking bolt 11, and two actuating devices 12, in this embodiment the two actuating devices 12 are identical.

[0025] The chamber 10 of the coupling element shown here is designed in two parts. It comprises two half chambers 13 and 14 which are screwed together along a central dividing plane 15 . The separating surface 15 extends longitudinally through the center of the through-opening 16 in the chamber 10 . Furthermore, with regard to the use position of the coupling element, which is shown in FIGS. 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com