Balance type double pulley

A dual-pulley, balanced technology, applied in door/window accessories, wing fan parts, wing fan suspension devices, etc., can solve problems such as frequent maintenance, affecting use, and easy damage to pulleys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] The present invention will be further described below in conjunction with accompanying drawing:

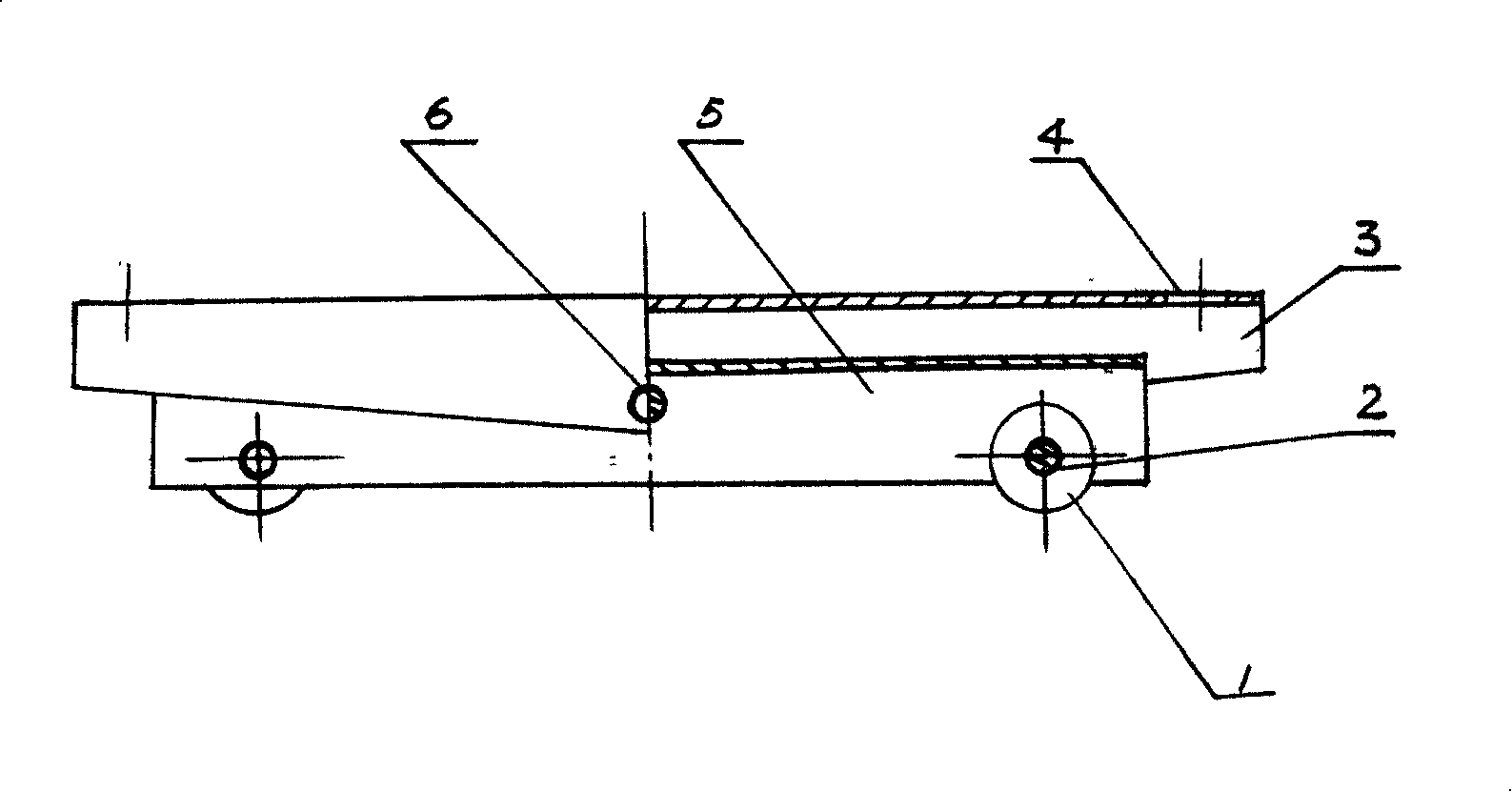

[0007] See accompanying drawing 1, the roller shaft (2) at both ends of the roller frame (5) passes through the roller (1) flexibly, and the roller shaft (2) is fixedly connected with the roller frame (5) to form a pulley; the balance shaft ( 6) pass through the connecting hole at the upper end of the roller frame (5) to form a flexible connection, and the two ends of the balance shaft (6) are fixed on both sides of the balance frame (3).

[0008] See attached drawing 1, the roller shaft (2) at both ends of the roller frame (5) passes through the roller (1) flexibly, and the two ends of the roller shaft (2) and the roller frame (5) are riveted to achieve a fixed connection , forming a pulley; the balance shaft (6) passes through the connecting hole at the upper end of the roller frame (5) to form a flexible connection, and the two ends of the balance shaft (6) are fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com