Intermittent type hole seeding device

A gap-type and hole-seeding technology, which is applied to fertilization devices, interval-type quantitative seeding machines, and planter parts, etc., can solve the problems of wasting manpower, single functions of machines and tools, and high purchase cost, and achieves strong matching, wide application range, The effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

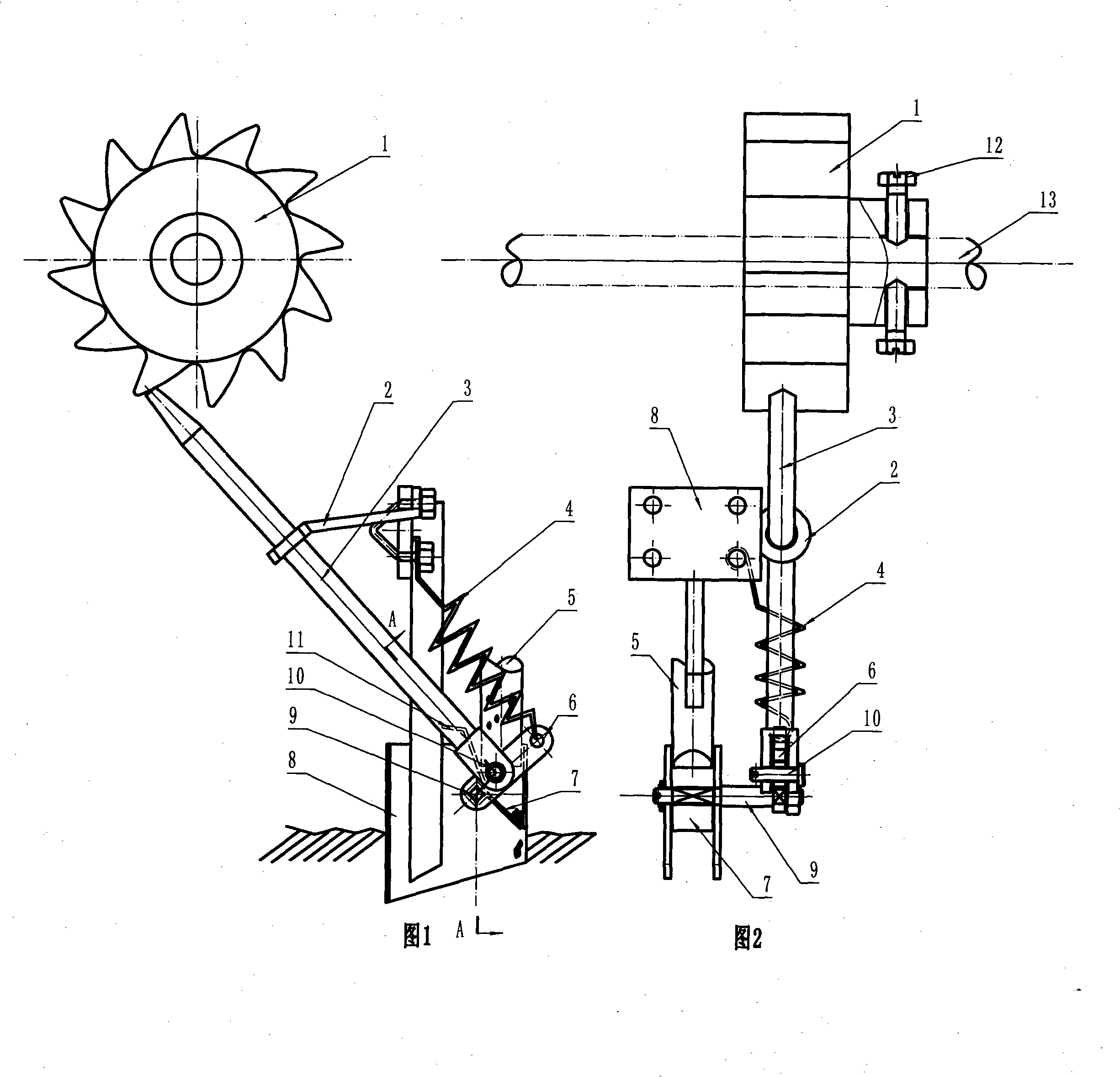

[0014] A fixed plate (11) is obliquely set in the travel device (8) of conventional seeding mechanism, and the fixed plate (11) is stuck on a fixed position in the travel device (8) with the seed drop pipe (5). Opening and closing plate (7) is arranged on the direct below of seed drop pipe (5), and it is fixedly connected with sowing opening and closing shaft (9), and sowing opening and closing shaft (9) is hinged on the travel device (8). One end of the sowing opening and closing shaft connecting plate (6) is fixedly connected with the sowing opening and closing shaft (9), and the other end is connected with the return spring (4).

[0015] The ratchet (1) is fixed on the seeding shaft (13) of the sower by a stop screw (12). The connecting guide rod (3) is inserted on the bracket (2), one end of the connecting guide rod (3) bears on the ratchet of the ratchet (1), and the other end connects with the sowing opening and closing shaft connecting plate (6) through the pin shaft (1...

Embodiment 2

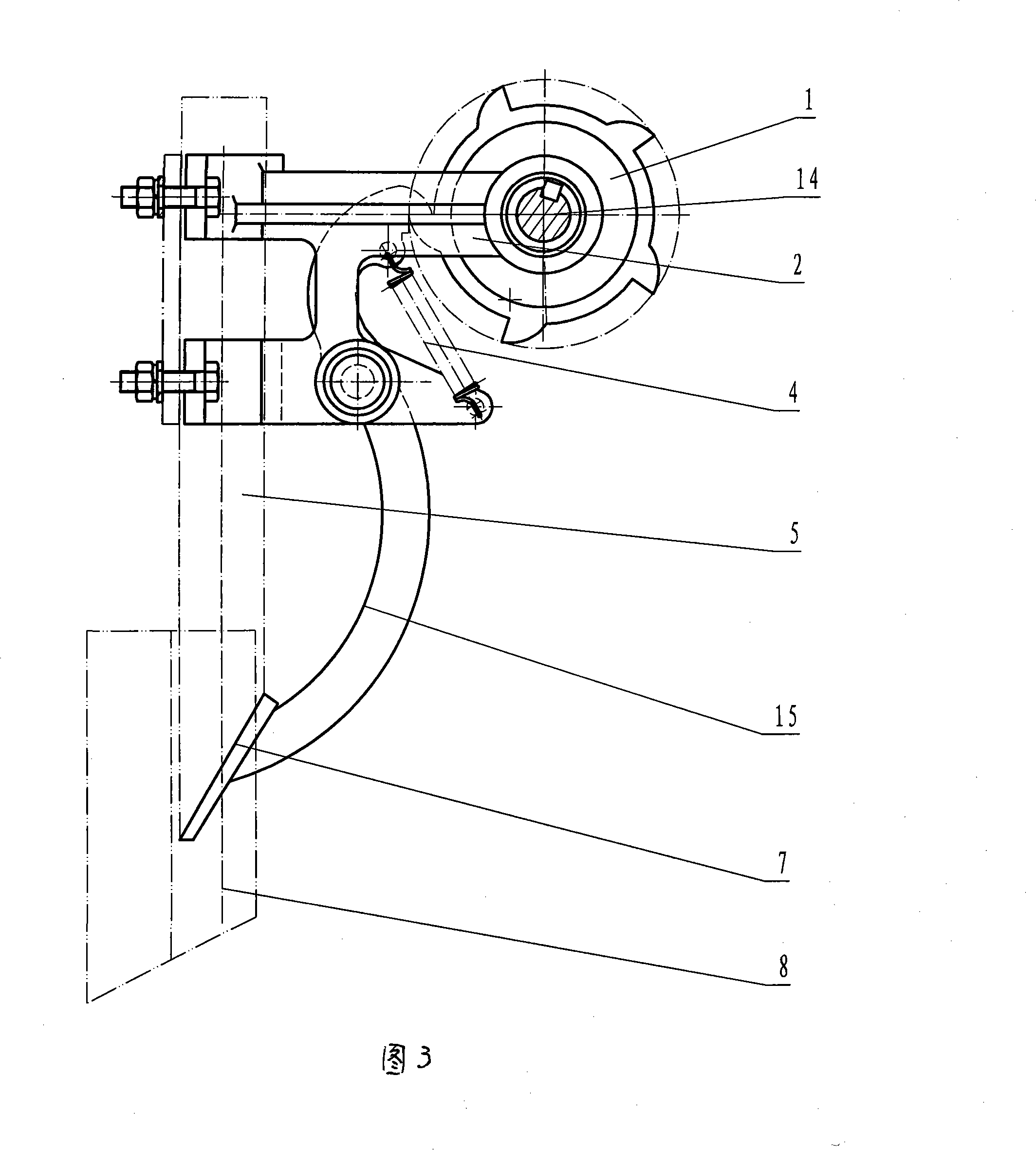

[0018] The interstitial hole sowing device is composed of an opening and closing plate (7) and a transmission mechanism. The transmission mechanism includes a ratchet (1), a bracket (2) and a sowing lever (15). The ratchet (1) is hinged on the bracket (2) through the ratchet shaft (14). ), the sowing lever (15) is also hinged on the support (2) through the shaft, and the stressed end of the sowing lever (15) is in contact with the ratchet of the ratchet (1), and the stressed end of the sowing lever (15) and There is a return spring (4) between the brackets (2), and the ratchet shaft (14) is driven by the seeding mechanism. When the ratchet shaft (14) drives the ratchet (1) to rotate, the ratchet will generate a gap thrust on the seeding lever (15) , under the combined action of the ratchet and the back-moving spring (4), the sowing lever (15) swings back and forth. The opening and closing plate (7) is fixed on the other end of the sowing lever (15), and the position of the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com