Interval type seeding mechanism

A kind of seeding mechanism and interstitial technology, which is applied in the field of the mechanism that can change the external grooved wheel seeder from drill sowing to hole sowing, which can solve the problems of high purchase cost and single function of the machine tool, so as to reduce the cost of use and facilitate the promotion of agricultural machinery Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] specific implementation plan

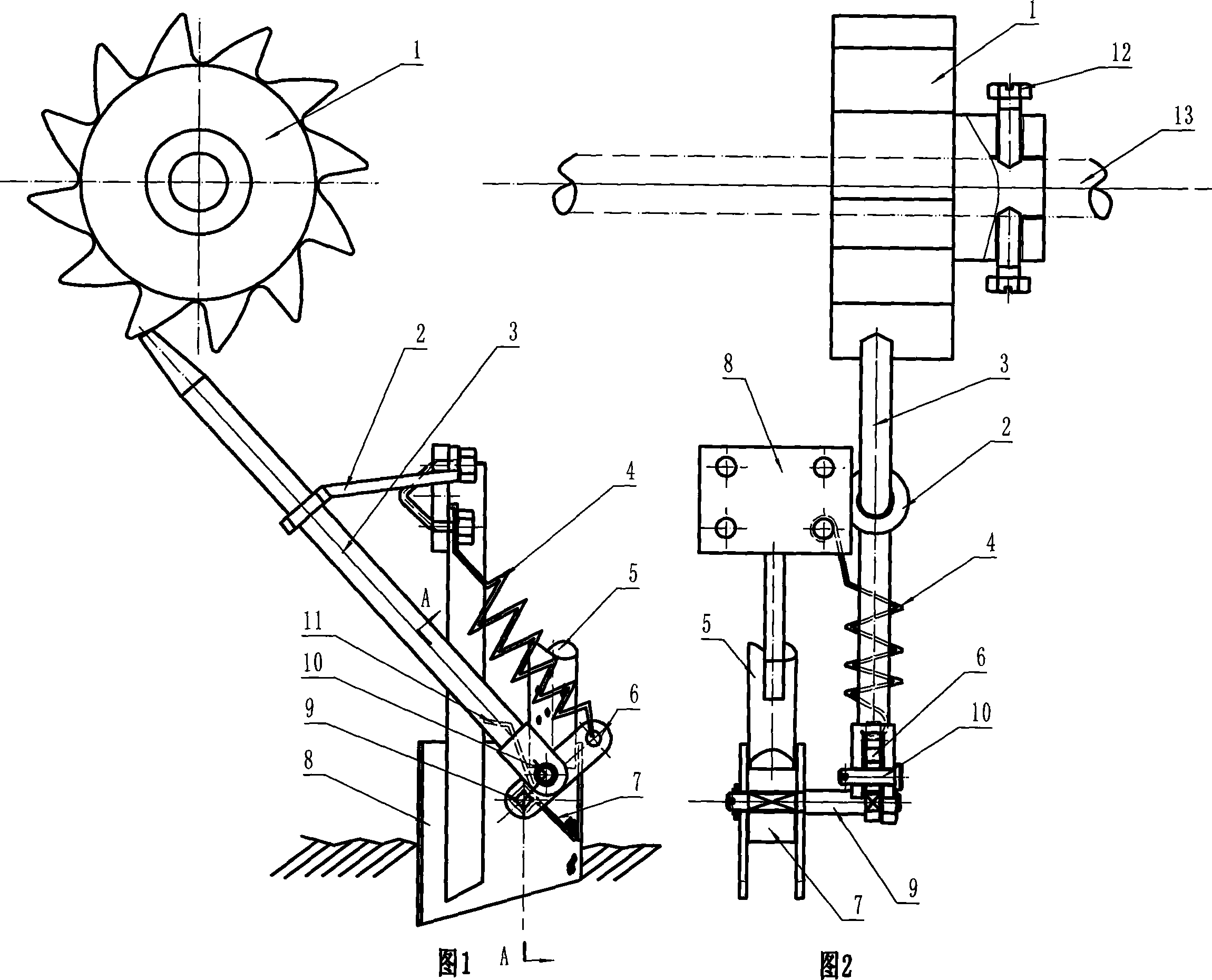

[0012] A fixed plate (11) is obliquely arranged in the opener (8) of the conventional rotary drill machine, and the fixed plate (11) clamps the seeding pipe (5) of the outer groove wheel type seeder on a in a fixed position. The opening and closing plate (7) is arranged directly below the seed pipe (5), and it is fixedly connected with the sowing opening and closing shaft (9), and the sowing opening and closing shaft (9) is hinged on the traveler (8). One end of the sowing opening and closing shaft connecting plate (6) is fixedly connected with the sowing opening and closing shaft (9), and the other end is connected with the return spring (4).

[0013] The ratchet (1) is fixed on the seeding shaft (13) of the outer grooved wheel type seeder by a stop screw (12). The connecting guide rod (3) is interspersed on the fixed frame (2), and one end of the connecting guide rod (3) bears against the ratchet of the ratchet (1), and the other end a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com