Asphalt recovery coating process

A coating and process technology, which is applied in the field of bitumen recovery coating vibrating reciprocating mixer and its bitumen coating process, can solve the problems of easy carbonization of stone surface and poor coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

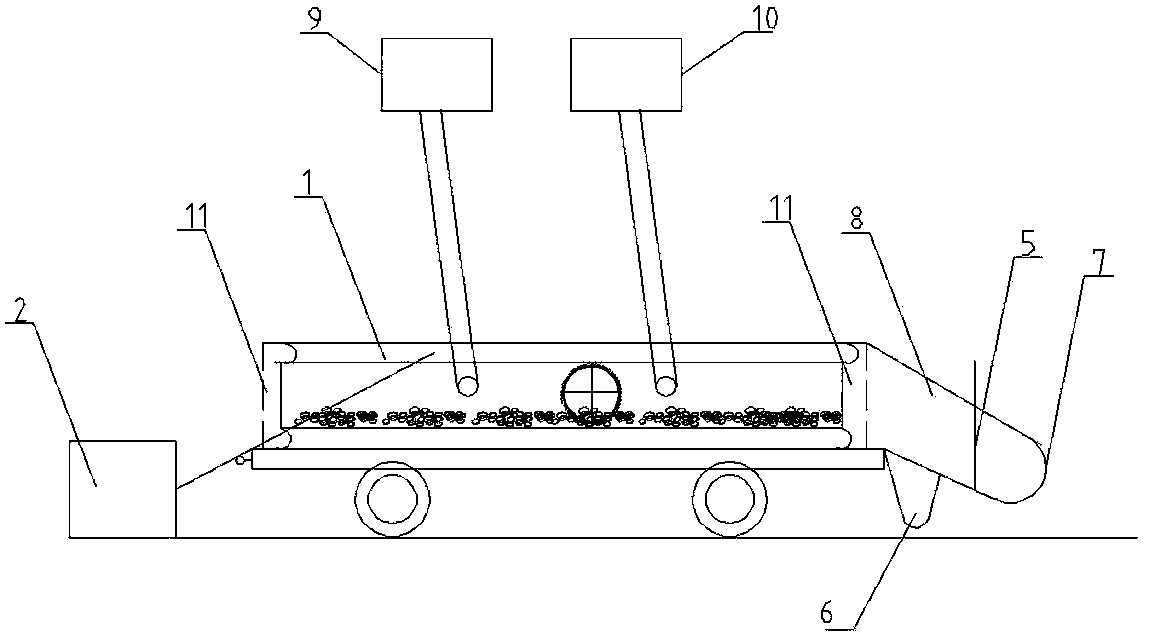

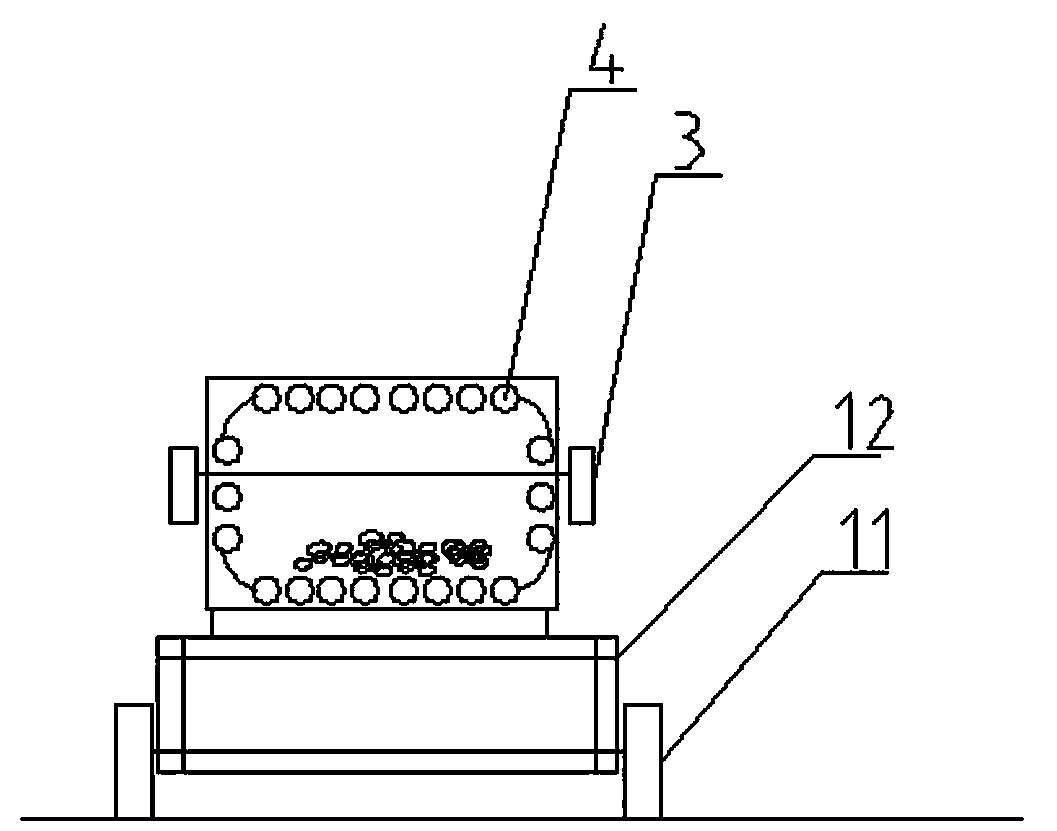

[0019] see figure 1 , 2 , leach recovery coating vibrating reciprocating mixer 28 includes reactor 1, heat transfer oil gas station 2, vibrator 3, both sides of reactor 1 are respectively provided with automatic insulation door 11, one side of reactor 1 is provided with The discharge bin 8 of the cold mix discharge port 7 and the hot mix discharge port 6 is provided with a cold and hot mix separation plate 5 inside the discharge bin 8, a heat conduction oil gas station 2 and a heat conduction plate arranged on the inner wall of the reaction kettle 1 The oil pipe 4 is connected, a vibrator 3 is arranged in the reaction kettle 1, and a shock absorbing device is arranged at the bottom of the reaction kettle 1 .

[0020] The reaction kettle 1 of the aforementioned bitumen recovery coating vibrating reciprocating mixer is connected with a minera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com