Organic fertilizer convenient to ferment

The technology of organic fertilizer and fermentation box is applied in the field of organic fertilizer that is easy to ferment, and can solve the problems of long time-consuming fertilizer, difficult dispersion of yeast, unfavorable production of organic fertilizer, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]A kind of organic fertilizer that is convenient to ferment, is made up of 30 parts of raw materials, and each part of raw materials includes leftovers 2kg (poultry viscera, such as abandoned intestines), beef extract 30g, peptone 15g, sodium chloride 45g, agar 150g, egg 200g (five pcs), oyster shells 300g (two), the balance is water.

[0036] The preparation method of organic fertilizer comprises the steps:

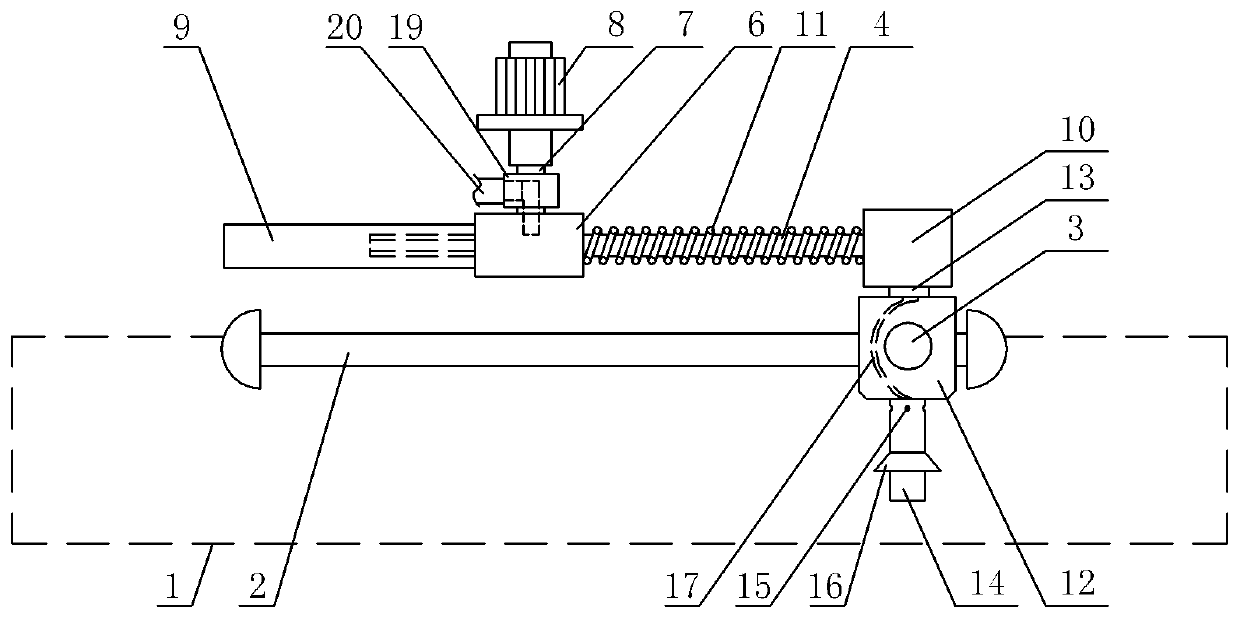

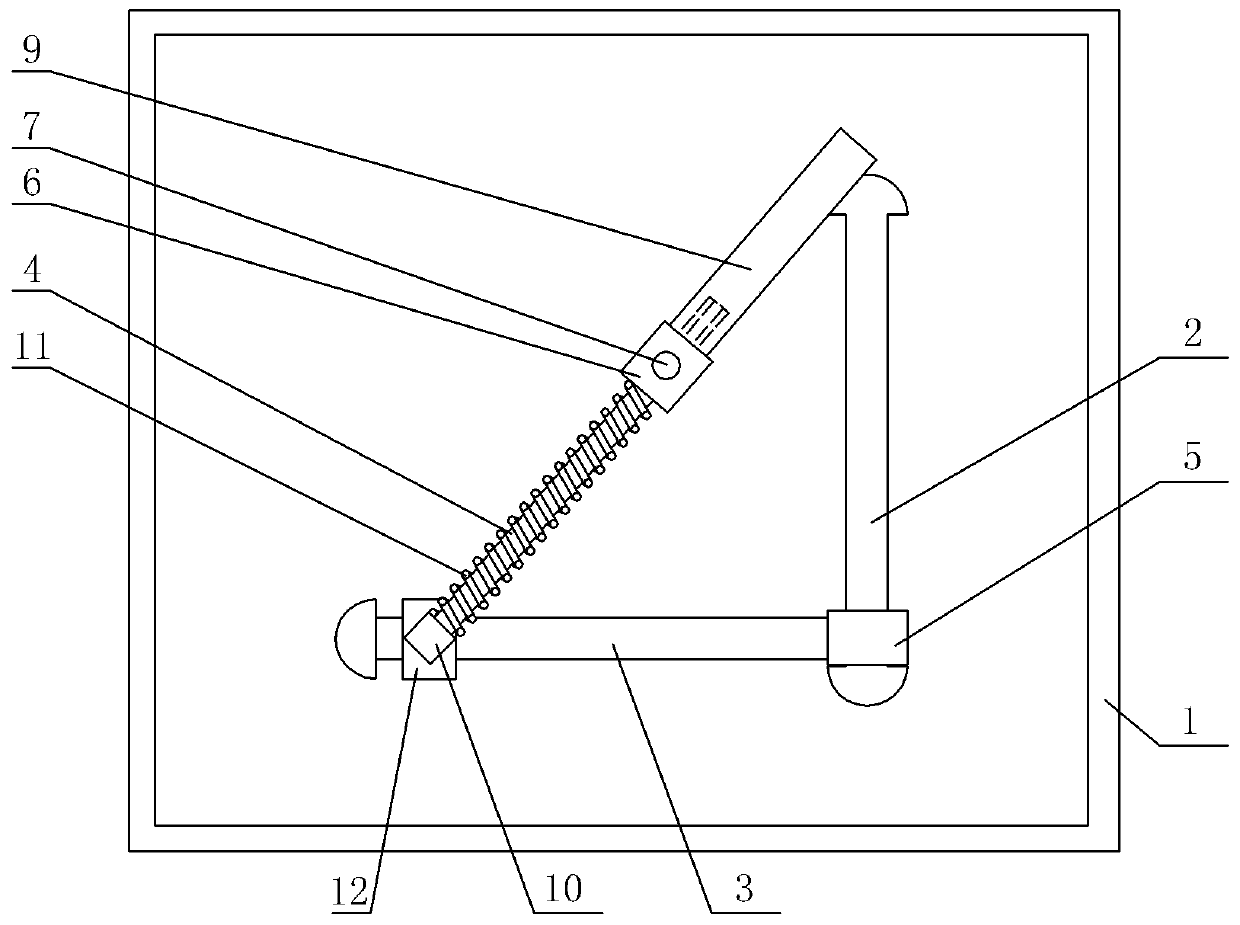

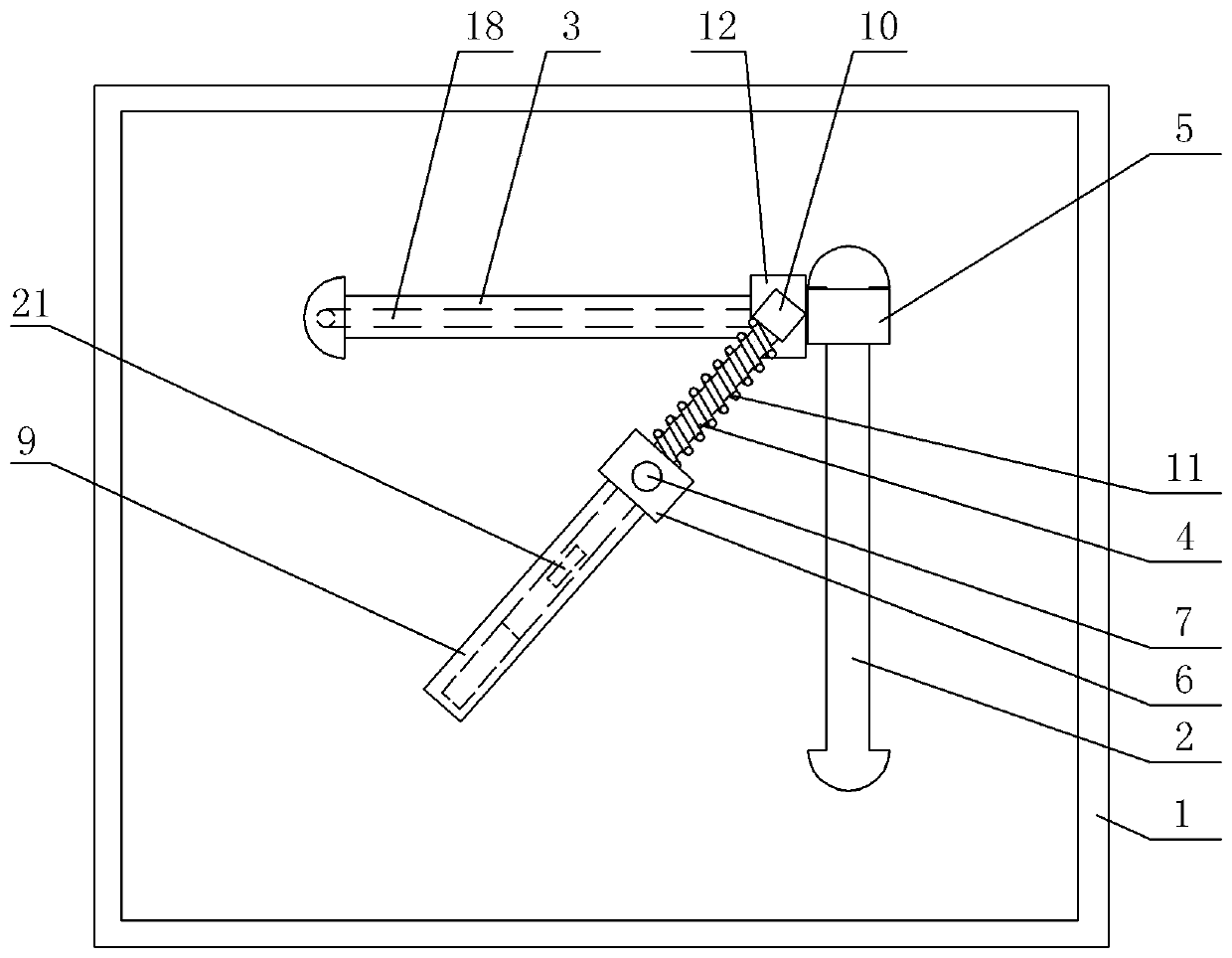

[0037] Step 1: Prepare raw materials and organic fertilizer preparation equipment, such as figure 1 , 4 The shown organic fertilizer preparation equipment comprises frame, No. 1 cylinder (not shown), fermenter 22, mixing mechanism and feeding mechanism, and No. 1 cylinder is fixed on the frame by bolts, and the output shaft of No. 1 cylinder The upper end is welded with a support plate, and the support plate is used to support the culture dish 1 . Such as figure 2 As shown, the mixing mechanism includes an I-shaped bar 2, a T-shaped bar 3, a T-shaped tube and a...

Embodiment 2

[0055] The difference with Example 1 is that each part of raw material includes 1.5kg of leftovers, 20g of beef extract, 10g of peptone, 40g of sodium chloride, 140g of agar, 160g of eggs (four), 150g of oyster shells (one), and the balance for water.

Embodiment 3

[0057] The difference with Example 1 is that each part of raw material includes 2.5kg of leftovers, 40g of beef extract, 20g of peptone, 60g of sodium chloride, 160g of agar, 240g of eggs (six), 450g (three) of oyster shells, and The amount is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com