Low-cost hot working die steel

A technology of hot work die steel and chemical composition, applied in the field of tooling and die, can solve the problems of rising smelting cost, and achieve the effects of good anti-tempering stability, good economic benefits and low cost

Active Publication Date: 2010-11-24

ADVANCED TECHNOLOGY & MATERIALS CO LTD

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, steel contains relatively high content of molybdenum and vanadium and other precious elements. In recent years, the price of molybdenum and vanadium alloys has risen sharply, resulting in a sharp increase in the smelting cost of H13 steel.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

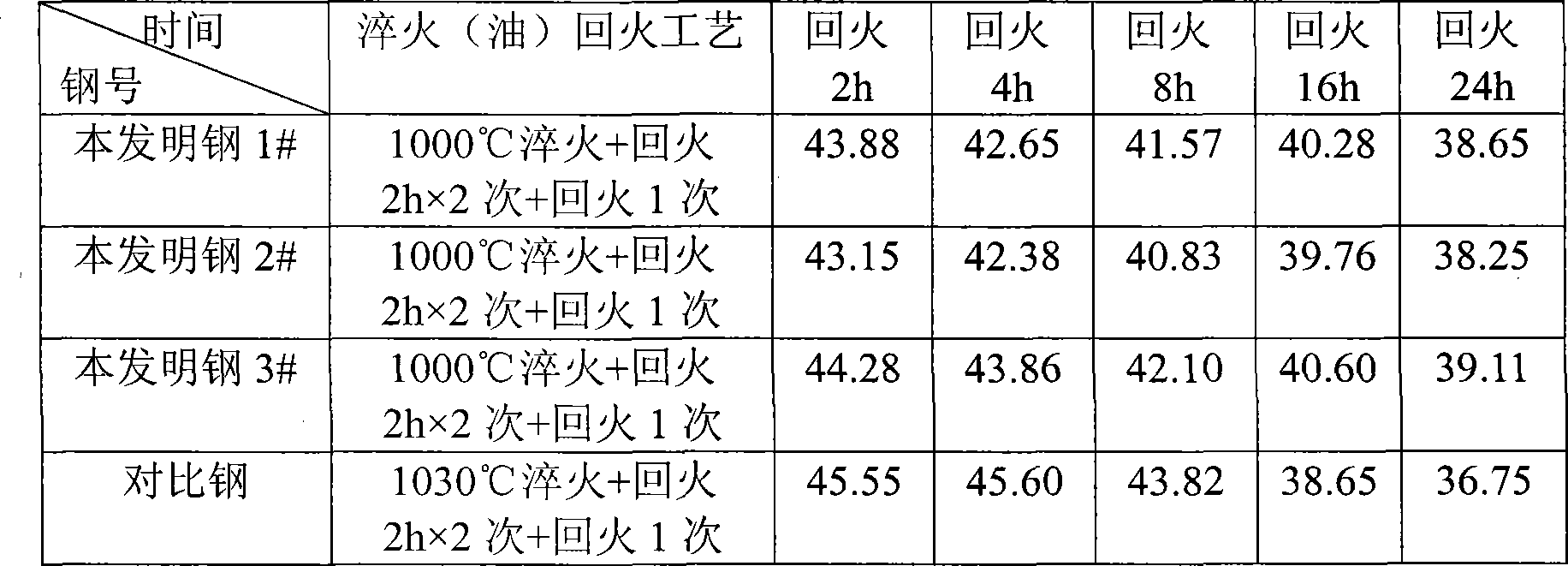

The invention belongs to the field of tool and die, specifically to a low-cost hot die steel. The chemical compositions of the steel (weigh%) are: C: 0.38-0.42%, Si: 0.9-1.1%, S<=0.030%, P<=0.030%, Mn: 0.3-0.5%, W: 0.9-1.2%, Mo: 0.45-0.55%, Cr: 4.8-5.2%, V: 0.25-0.45%, Nb: 0.08-0.15% and Fe and unavoidable impurities: the blance. The steel of the invention can be used as a substitute for high-alloy-containing H13, has similar comprehensive performance to H13, superior temper resistance and low chromium; the rational alloy ratio saves cost more than 20%, compared with H13 steel, thus having better economical benefit.

Description

A low-cost hot work die steel technical field The invention belongs to the field of tools and molds. It is mainly used in the manufacture of hot extrusion abrasive tools and core rods, forging dies for die forging hammers, forging press dies, die inserts for precision forging machines, and die-casting dies for aluminum, copper and their alloys. In particular, it relates to a low-cost hot work die steel. Background technique With the development of machinery manufacturing industry, higher requirements are put forward for the performance and economic cost of hot work die steel. H13 steel is the most widely used and most representative hot work die steel. V is the main strengthening element, which has good strength and toughness, while maintaining high thermal fatigue resistance, so it can withstand high temperature tension, compression and impact, and can also withstand high temperature wear, oxidation and periodic temperature changes of shock and heat And so on. However,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/26

Inventor 马党参陈再枝刘建华张晨周健

Owner ADVANCED TECHNOLOGY & MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com