Single spray gun structure RH fining furnace soaking tube spraying machine

A technology of refining furnace and dipping tube, applied in the field of RH refining furnace dipping tube gunning machine, which can solve the problems of dipping tube scrapping, difficult operation, loss of steel plant, etc., and achieve flexible gunning action, precise positioning action, and springback The effect of less material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

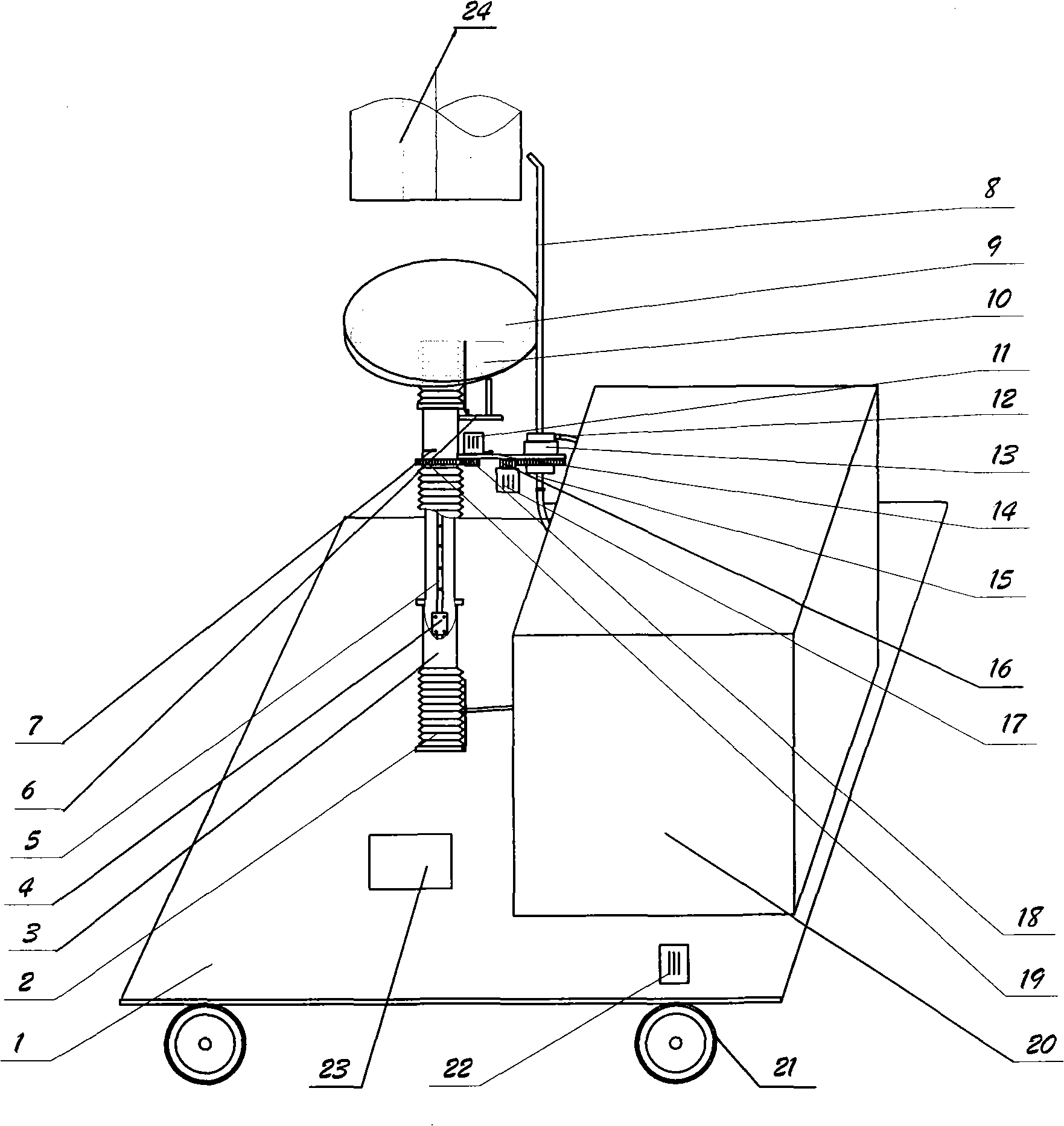

[0024] Such as figure 1 Shown, the RH refining furnace immersion tube gunning machine of single spray gun structure of the present invention is characterized in that by walking trolley, the spray gun frame device that is arranged on this walking trolley, the spray gun that is arranged on this spray gun frame device and It is composed of the spray gun rotary device, the spray gun self-running device and the auxiliary system connected with the above-mentioned various devices set on the walking trolley.

[0025] 1) The spray gun frame device is arranged on the trolley, and is composed of a base 1 on the trolley, a column 3 arranged on the base 1 and a crossbeam 9 arranged at the upper end of the column 3. Both sides of the column 3 are provided with a guide rail 5 and a column-wrapping disc 6 that slides and fits with the guide rail 5,

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com