Flood chamber for coating installations

A perfusion chamber and perfusion technology, applied in the field of perfusion chambers, can solve problems such as short perfusion time, and achieve the effect of offsetting the swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

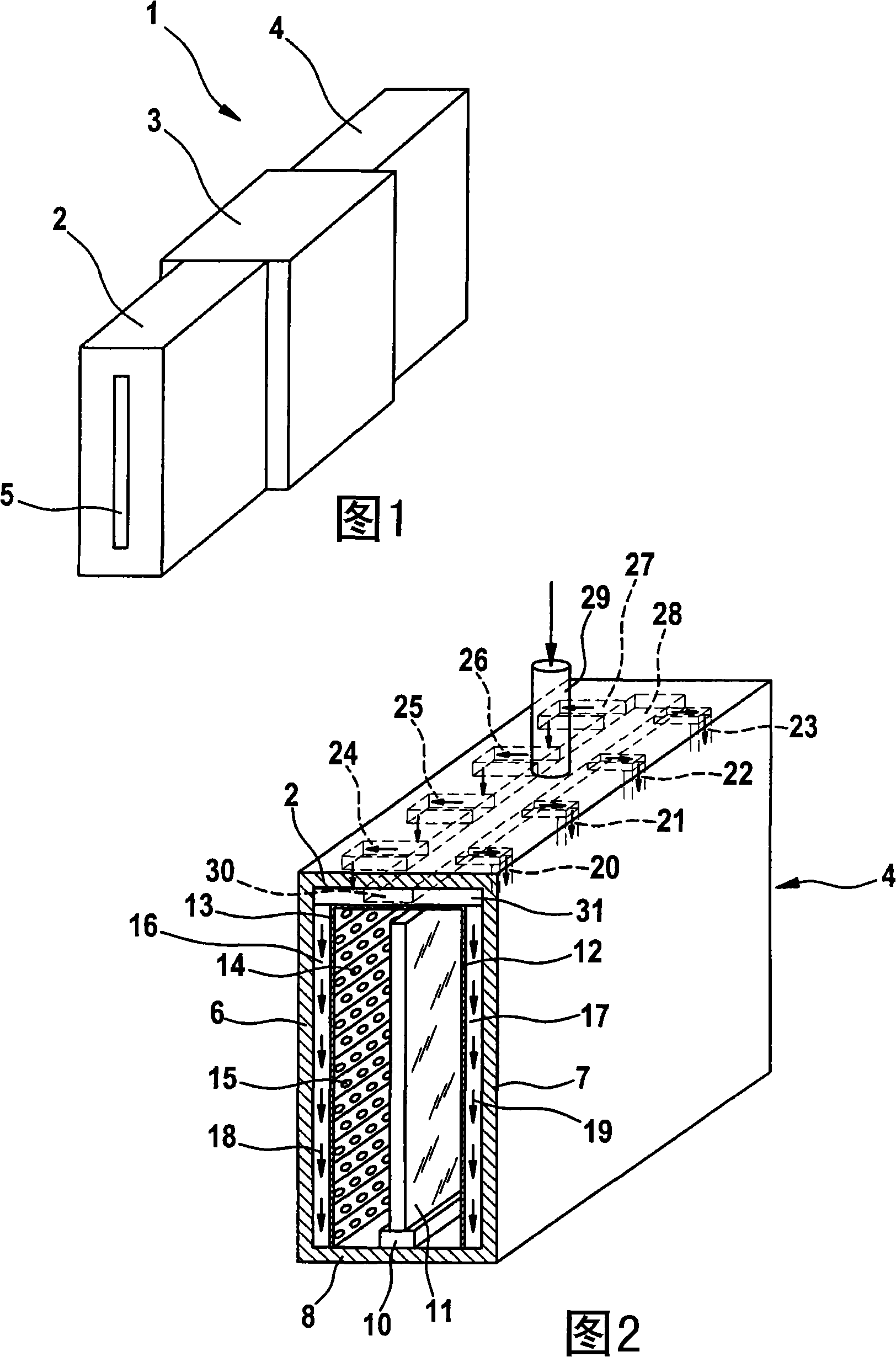

[0040] FIG. 1 shows a schematic diagram of an in-line coating plant 1 with an inlet chamber 2 , a treatment chamber 3 and an outlet chamber 4 . The surface substrate to be coated (for example a glass plate) is introduced through the opening 5 of the feed chamber 2 and transported to the treatment chamber 3, where the substrate is coated. After coating, the substrate reaches the discharge chamber 4 and from there is transported to the outside.

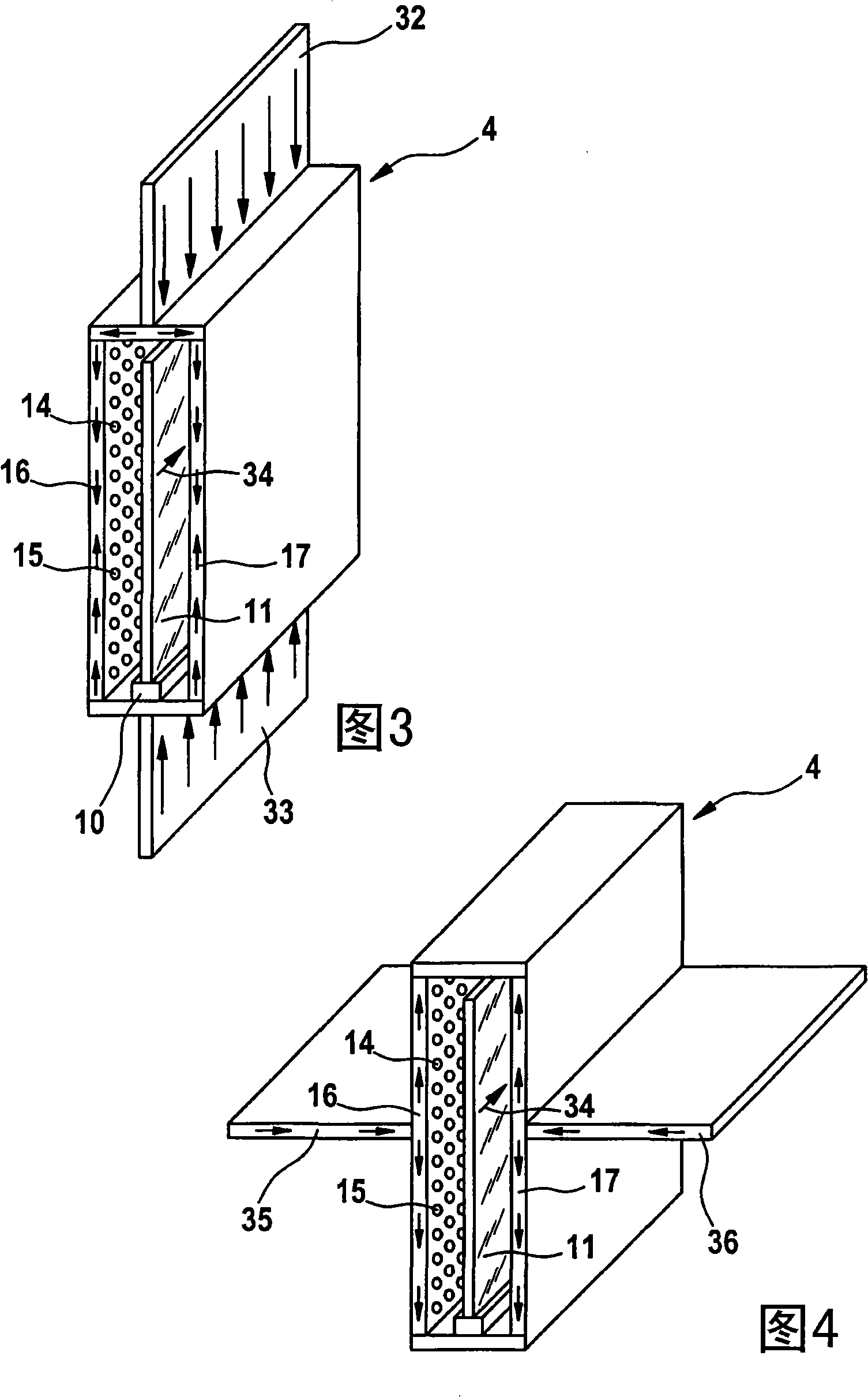

[0041] FIG. 2 again shows the tap chamber 4 isolated. The four lock chamber walls 6 to 9 and the transport device 10 for the substrate 11 (here a glass plate) can be seen. The perfusion walls are indicated with 12 and 13 and provided with holes 14,15. The perfusion walls 12 , 13 together with the interior of the locking chamber walls 6 , 7 form perfusion channels 16 , 17 through which gas flows and subsequently through the holes 14 , 15 . The gas flow is indicated by arrows 18 , 19 . Feed via a gas supply pipe 29 , the gas supply ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com