Single-plate anti-misplugging leading block and single-plate device with the same

A guide block and anti-mis-insertion technology, applied to the circuit layout of the support structure, the combination of component plug-ins, the rack/frame structure, etc., can solve the problems of high cost, few changes, complex structure, etc. Simple, convenient and quick-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

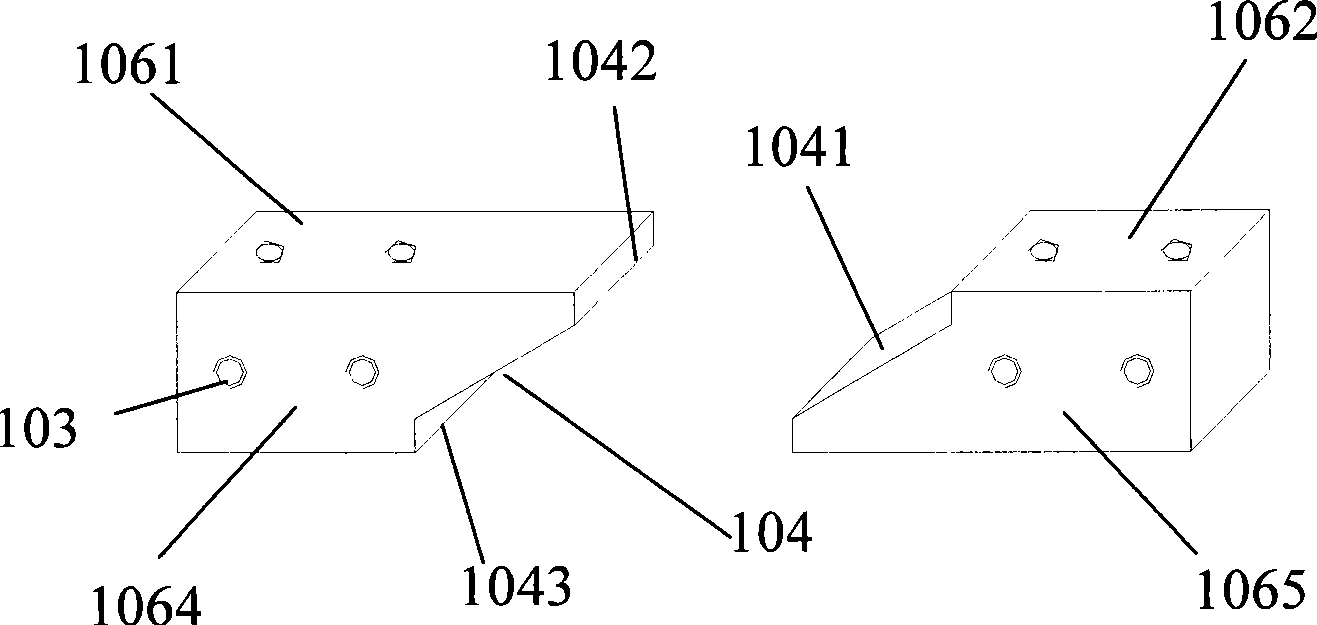

[0028] Such as Figure 2a and 2b As shown, the cylinder of the veneer misinsertion prevention guide block 03 is in the shape of a square, and its matching positioning surface 104 has an inclined surface 1041, and the two ends of the inclined surface 1041 have vertical surfaces 1042 and 1043, when the vertical surface is mated, it can improve the safety and safety strength of mated mating. When the two anti-mis-insertion guide blocks are matched, the positioning surfaces 104 of the two anti-mis-insertion guide blocks are bonded together. If it cannot be inserted in place, it can prevent mis-insertion. Taking the positioning surface of the guide block as the front, its four sides, the bottom side 1061, the upper side 1062, the left side 1063 and the right side 1064 can all be used as the cylinder mounting surface, and the mounting hole 103 is arranged on the mounting surface, so The mounting hole mentioned above is a through hole, and the mounting hole can be a threaded hole ...

Embodiment 2

[0035] In another embodiment of the present invention, the cylinder of the anti-mis-insertion guide block is connected with a shell with at least one end open, the cylinder is installed in the shell through the open end of the shell, and the positioning surface is located outside the shell.

[0036] The shape of the housing can be the same as that of the cylinder, and the cylinder and the shell can be connected by any active connection structure in the prior art. For example, the mounting surface of the cylinder has a slide groove, and the connecting surface of the shell and the cylinder has a corresponding slide The rail and the cylinder can be movably connected as a whole through the chute and the slide rail. By connecting different sides of the cylinder with the shell, the position of the cylinder can be adjusted, and multiple anti-misplug combinations can be realized. The shell has a connection surface with the single board, and the connection surface is connected with the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap