Patents

Literature

39results about How to "Solve the crash problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for positioning faulted memory in linux system

InactiveCN103198000ASolve the crash problemSolve problems such as blue screenDetecting faulty computer hardwareHardware monitoringMemory faultsGNU/Linux

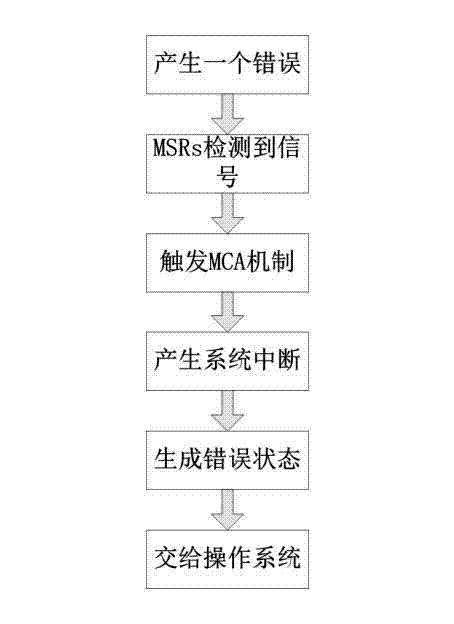

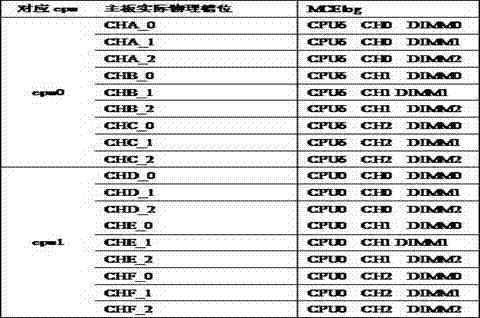

The invention provides a method for positioning a faulted memory in a linux system. The method comprises that error types and fault positions of the faulted memory are judged quickly and problems such as server halting and blue screens caused by memory faults are solved quickly by usage of mcelog records produced by the system according to the actual physical slot comparison relationship without regard to judgments and records of memory faults provided by a mainboard baseboard management controller (bmc). Compared with existing memory fault judgment methods, the method has the advantages that the method is independent of a memory fault tracking and positioning function of the mainboard bmc; on-site repetition of pressure tests to wait for faults and exchange of memory tests to position the faulted memory are not required, and the fault appearance frequency, fault reasons and fault positions can be determined quickly according to generated mcelog logs; and the implementation method is simple, and the efficiency for judgment and solving of problems can be improved.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

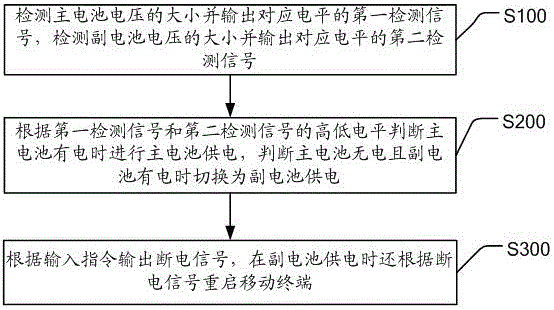

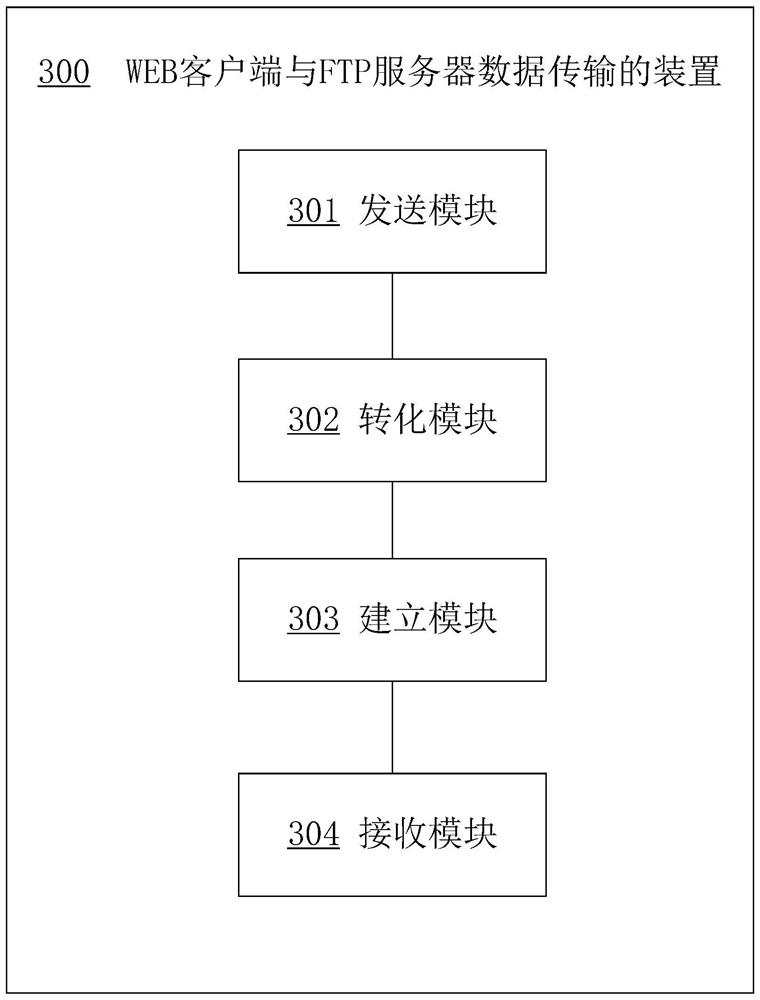

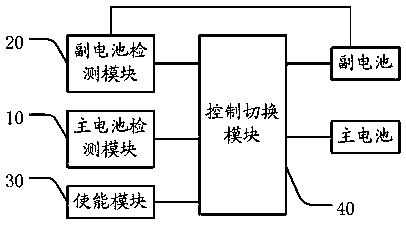

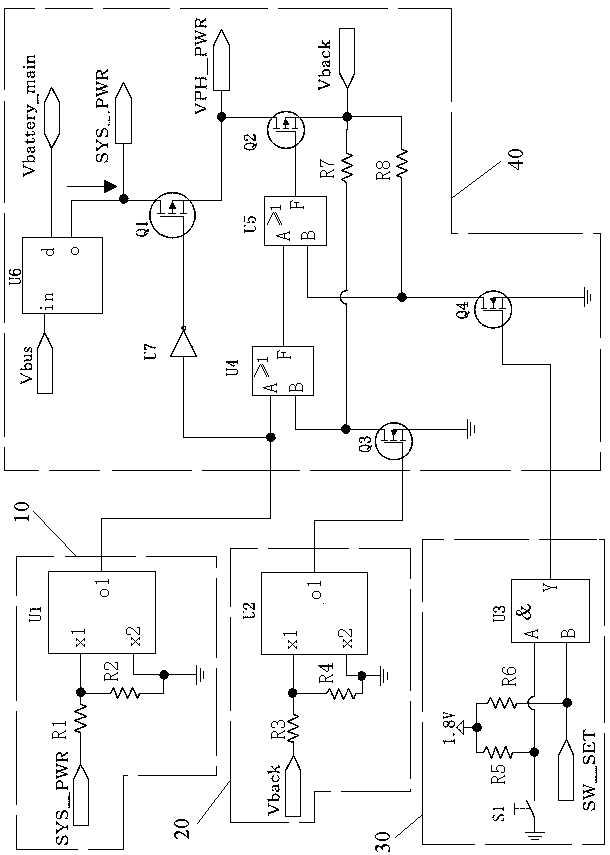

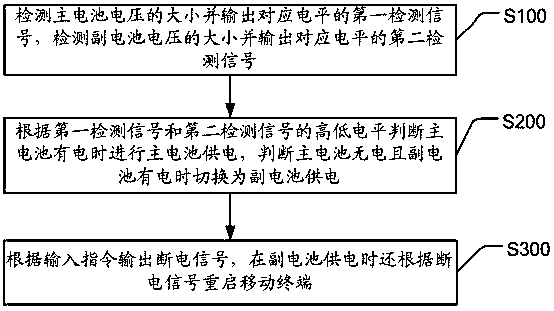

Mobile terminal dual-battery control device and method

ActiveCN106532902ASolve the crash problemTroubleshoot the systemEnd cell switching arrangementsEmergency power supply arrangementsElectricityElectrical battery

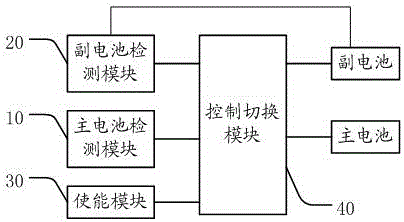

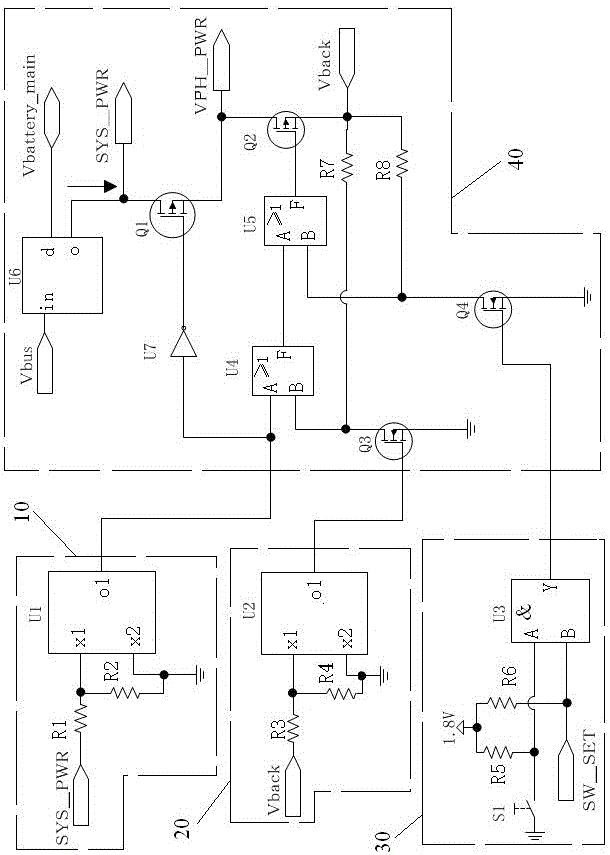

The present invention discloses a mobile terminal dual-battery control device and method. The dual-battery control device is connected with a main battery and a secondary cell and comprises a main battery detection module, a secondary battery detection module, an enabled module and a control switching module. The main battery detection module detects the size of the main battery voltage and output the first detection signals corresponding to the level. The secondary cell detection module detects the size of the secondary cell voltage and outputs the second detection signals corresponding to the level. The enabled module outputs outage signals according to the input instruction. The main battery supplies power when the control switching module determines that the main battery has electricity supply according to the high-low level of the first detection signals and the second detection signals, the secondary cell supplies power when the control switching module determines that the main battery has no electricity supply and the secondary cell has the electricity supply, so that the man battery power supply is automatically switched to the secondary cell power supply when the main battery has no electricity supply, and the main battery can be replaced in the turn-on state. When the secondary cell supplies power, the mobile terminal can be restarted according to the outage signals to solve the problems of crashing of the mobile terminal or system faults.

Owner:厦门九品芝麻信息科技有限公司

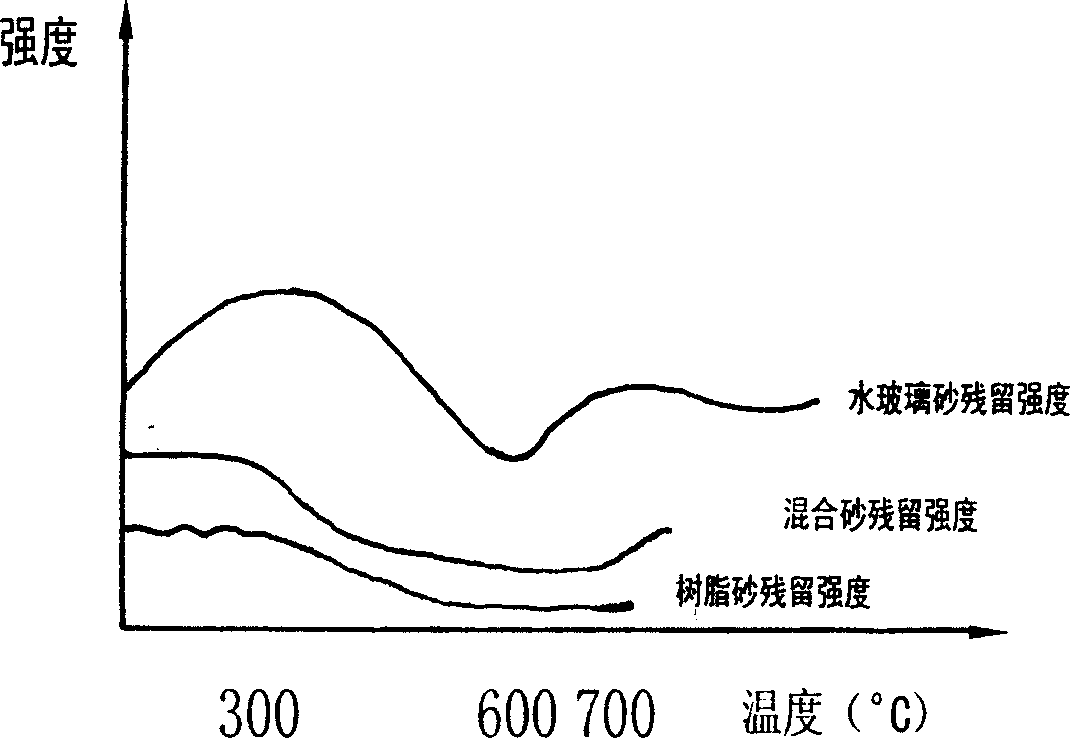

Water glass and resin mixed CO2 hardening method

ActiveCN1613573AReduce the amount addedHigh strengthFoundry mouldsFoundry coresResin adhesivePolyresin

A CO2 hardening method for the mixture of water glass and resin used for casting sand mould includes such steps as proportionally mixing the sand, water glass and resin, forming mould, and introducing CO2 gas to harden the mould. It features that after casting, the resin adhesive prepared from water glass and resin is carbonized, resulting in high collapsibility.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

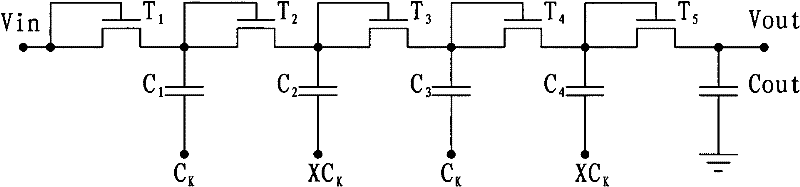

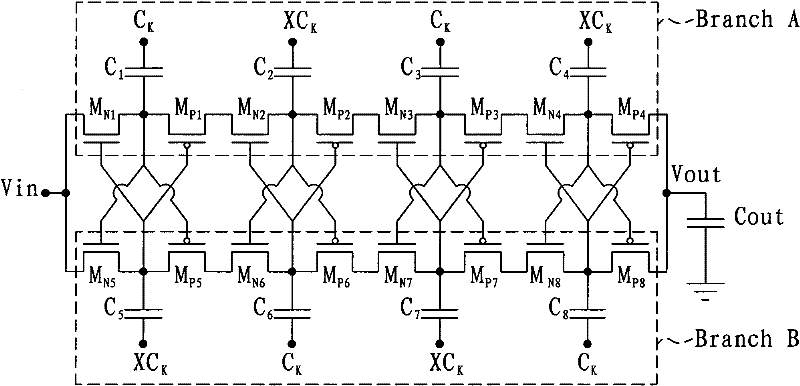

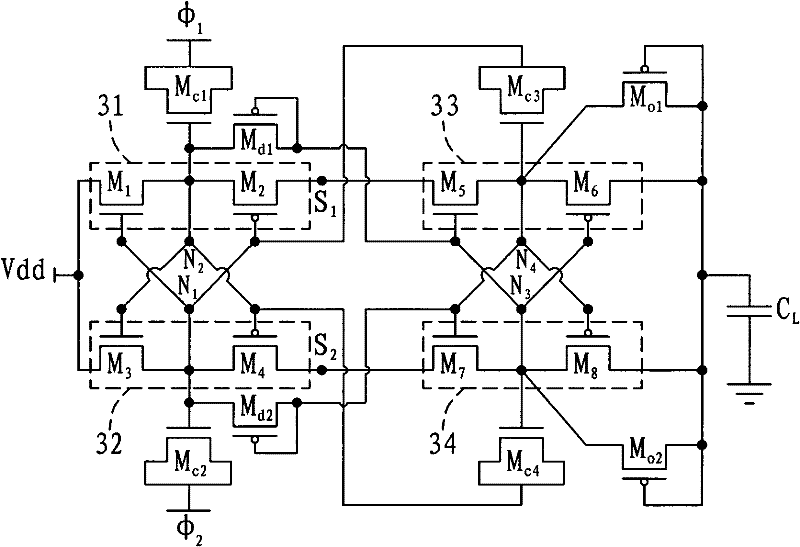

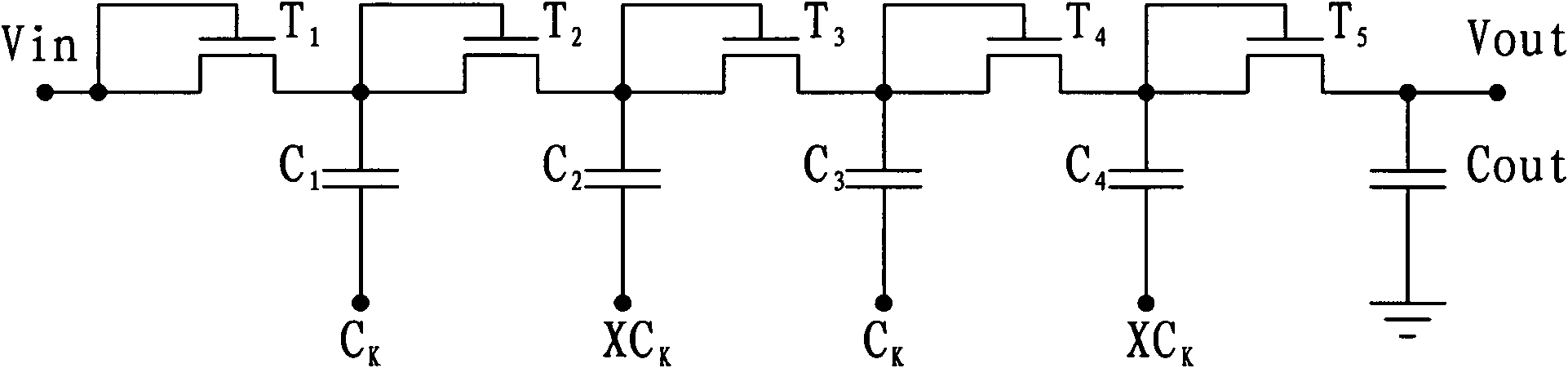

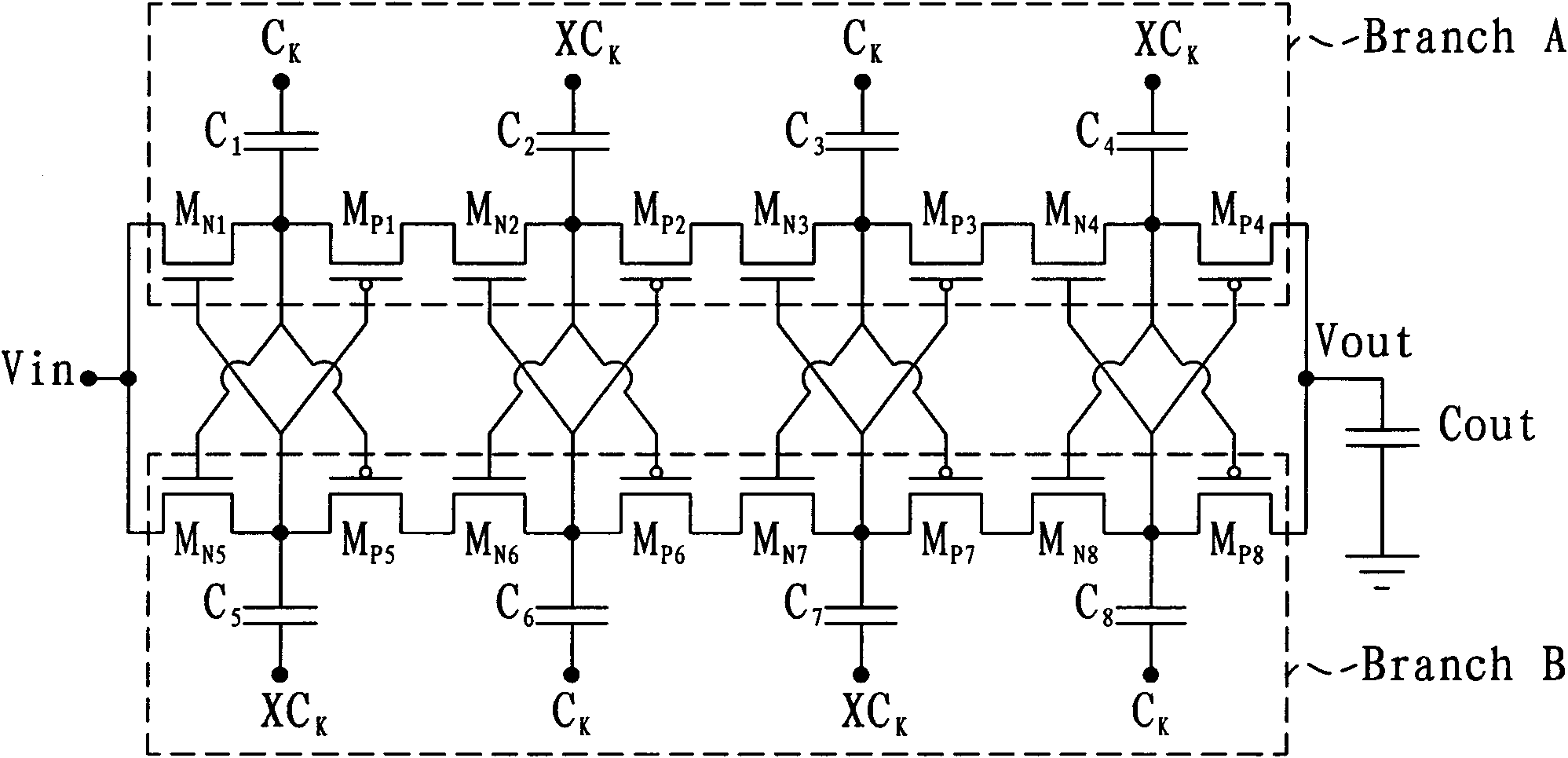

Charge pump

ActiveCN102347687ASolve the crash problemApparatus without intermediate ac conversionConnection typeCapacitance

The invention relates to a charge pump. The charge pump can amplify an input voltage which is received at an input end and output the amplified output voltage at an output end. The charge pump comprises a plurality of transistors of which sources and drains are coupled, a plurality of overlapped transistors and a plurality of diode connection type transistors, wherein the transistors of which the sources and the drains are coupled serve as charging capacitors; the overlapped transistors are connected between the input end and the output end in a symmetric arrangement mode; and the diode connection type transistors are used for preventing the transistors of which the sources and the drains are coupled from being broken down in a charge transfer process and improving a charge transfer speed. The charge pump can be integrated on a chip by replacing the charging capacitors with the transistors of which the sources and the drains are coupled; and the problem of breakdown of the transistors can be solved by arranging the diode connection type transistors in the charge pump.

Owner:ACER INC

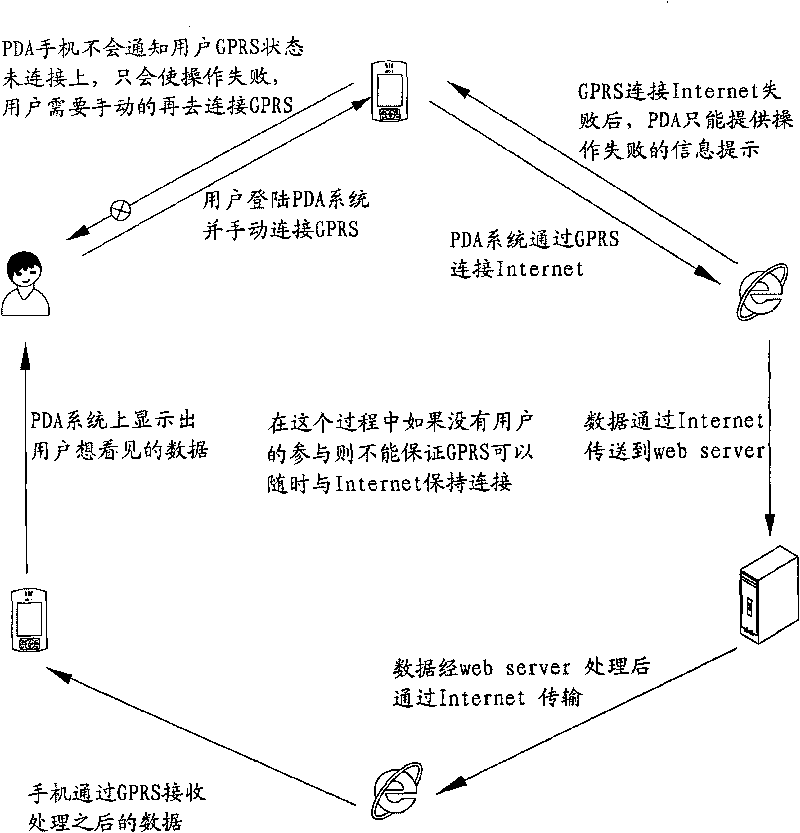

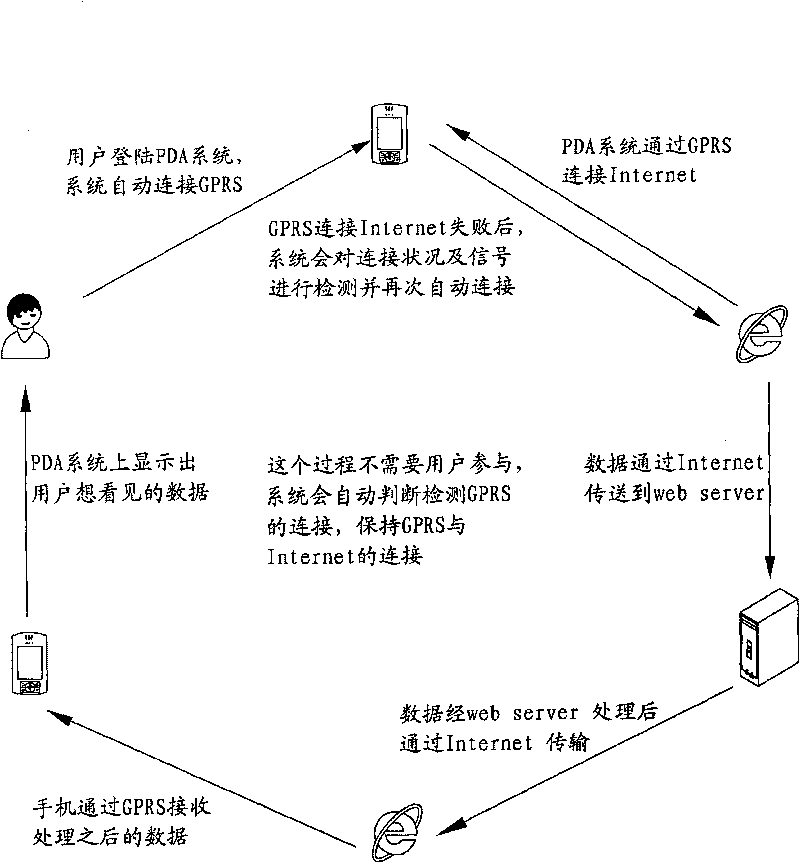

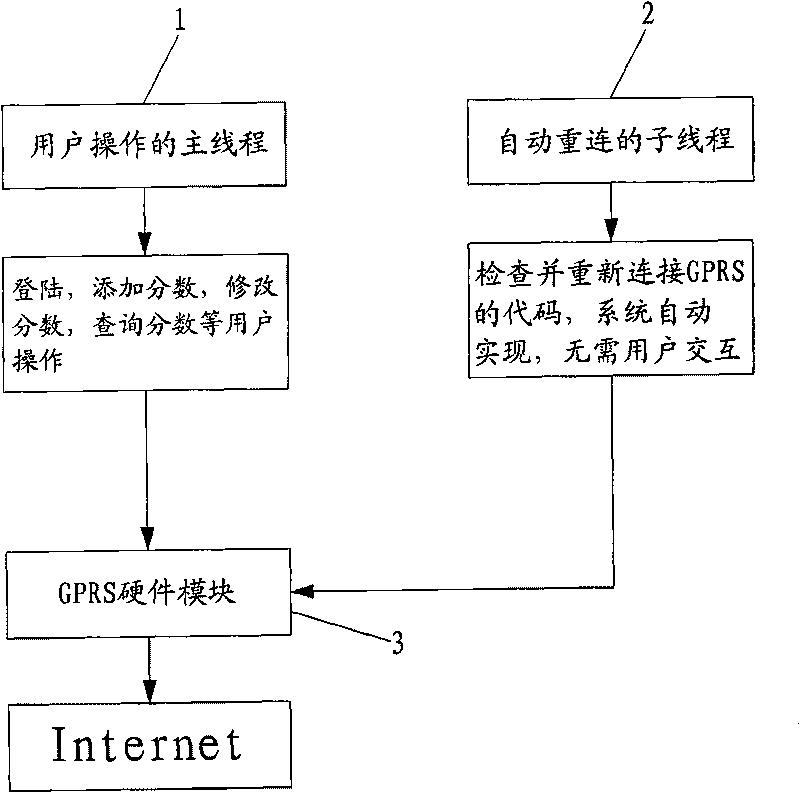

Method for keeping real-time online of scoring system based on mobile communication network

The invention relates to a method for keeping the real-time online of a scoring system based on mobile communication network. The mobilephone system is additionally provided with an automatic reconnection sub-thread outside a user operation main thread which is in charge of processing user operations; the automatic reconnection sub-thread is in charge of intermittently checking whether the mobilephone is disconnected or not, and if the mobilephone is disconnected, a wireless network is automatically reconnected; outputted data of the user operation main thread and the automatic reconnection sub-thread is respectively connected to the internet by a wireless communication module to realize data exchange with a server; and when the user operation main thread and the automatic reconnection sub-thread simultaneously use the wireless communication module, a thread lock is applied to the thread which firstly uses the wireless communication module, and the other thread waits for the occurrence of the idle state of the wireless communication module. The method can keep the real-time online of the scoring system, and reduces the generation of misoperation, dead halt and locking, thereby increasing the reliability and the accuracy of data transmission and being more convenient to use.

Owner:大连三通科技发展有限公司

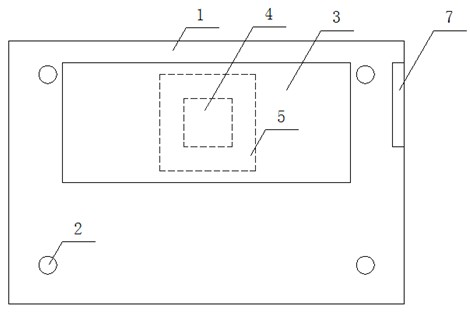

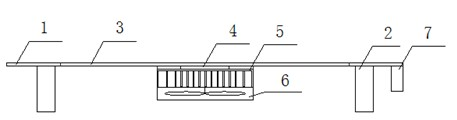

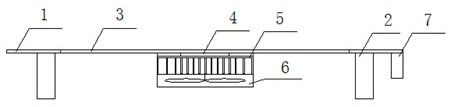

Semiconductor refrigerating cooling pad for laptop

InactiveCN101980101AImprove cooling effectLow costDigital data processing detailsEngineeringComputer software

The invention relates to a semiconductor refrigerating cooling pad for a laptop. A semiconductor refrigerating piece is the core of equipment, arranged in a cushion of the laptop and opposite to a laptop hard disk and a central processing unit (CPU) area, and provides cold quantity required by cooling the laptop; a heating conducting plate quickly and approximately uniformly diffuses the cold quantity produced by the semiconductor refrigerating piece to the lower part of the laptop; and a fan and a fin assist the hot end of the semiconductor refrigerating piece in dissipating heat to enhance the refrigerating effect of the cold end of the semiconductor refrigerating piece. The semiconductor refrigerating cooling pad for the laptop has high heat dissipation capability and low manufacturing cost, is light and portable, and can solve the problems of blue screen and crash caused by overhigh temperature of a CPU and a display card for large computer software users, computer game enthusiasts and users who are fond of realizing the overclocking phenomenon of the CPU.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

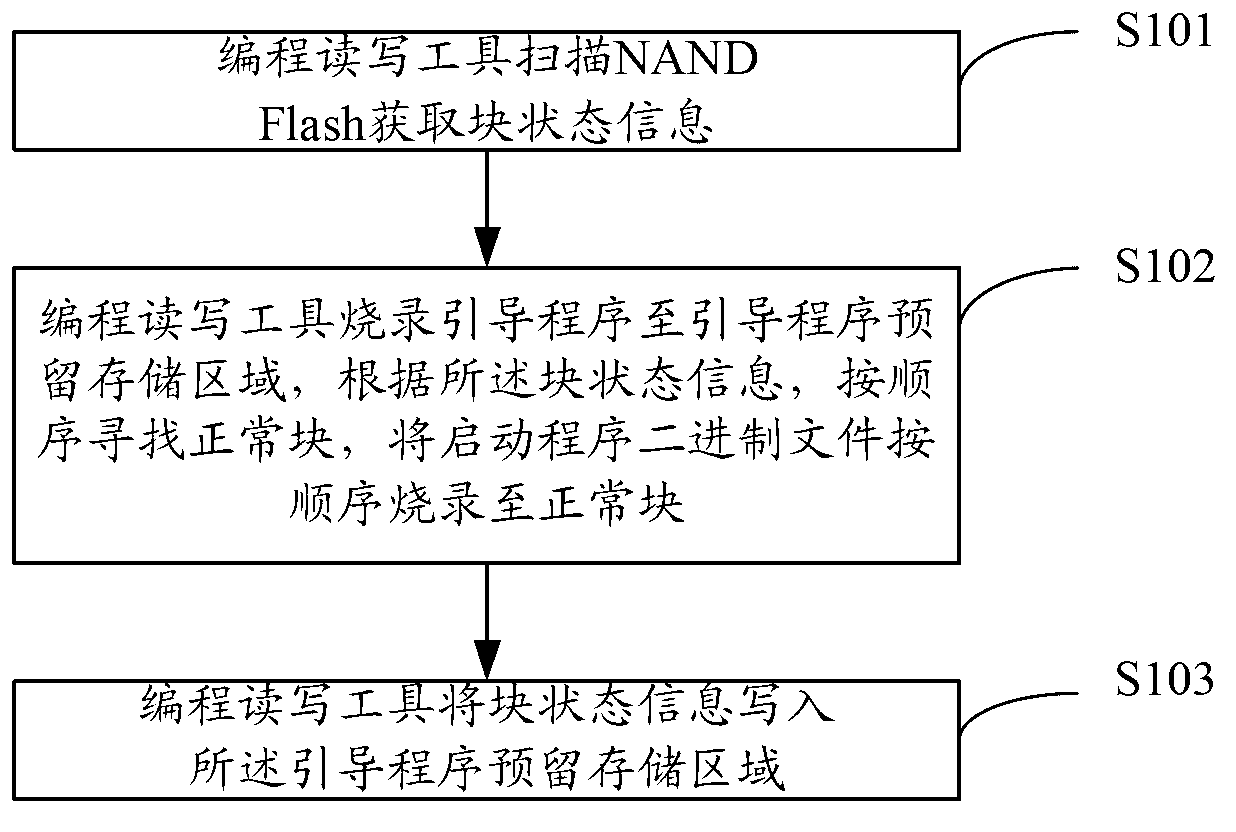

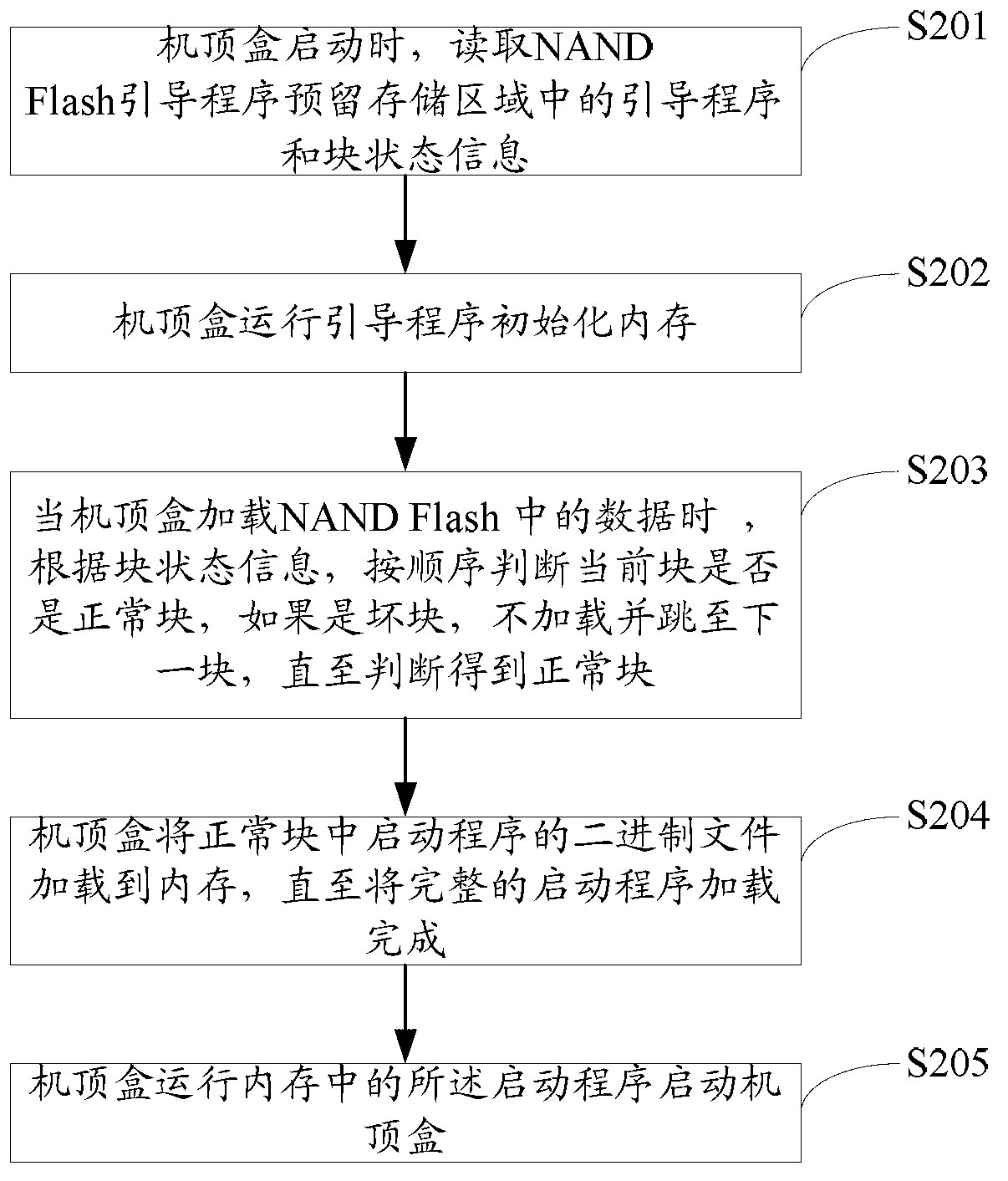

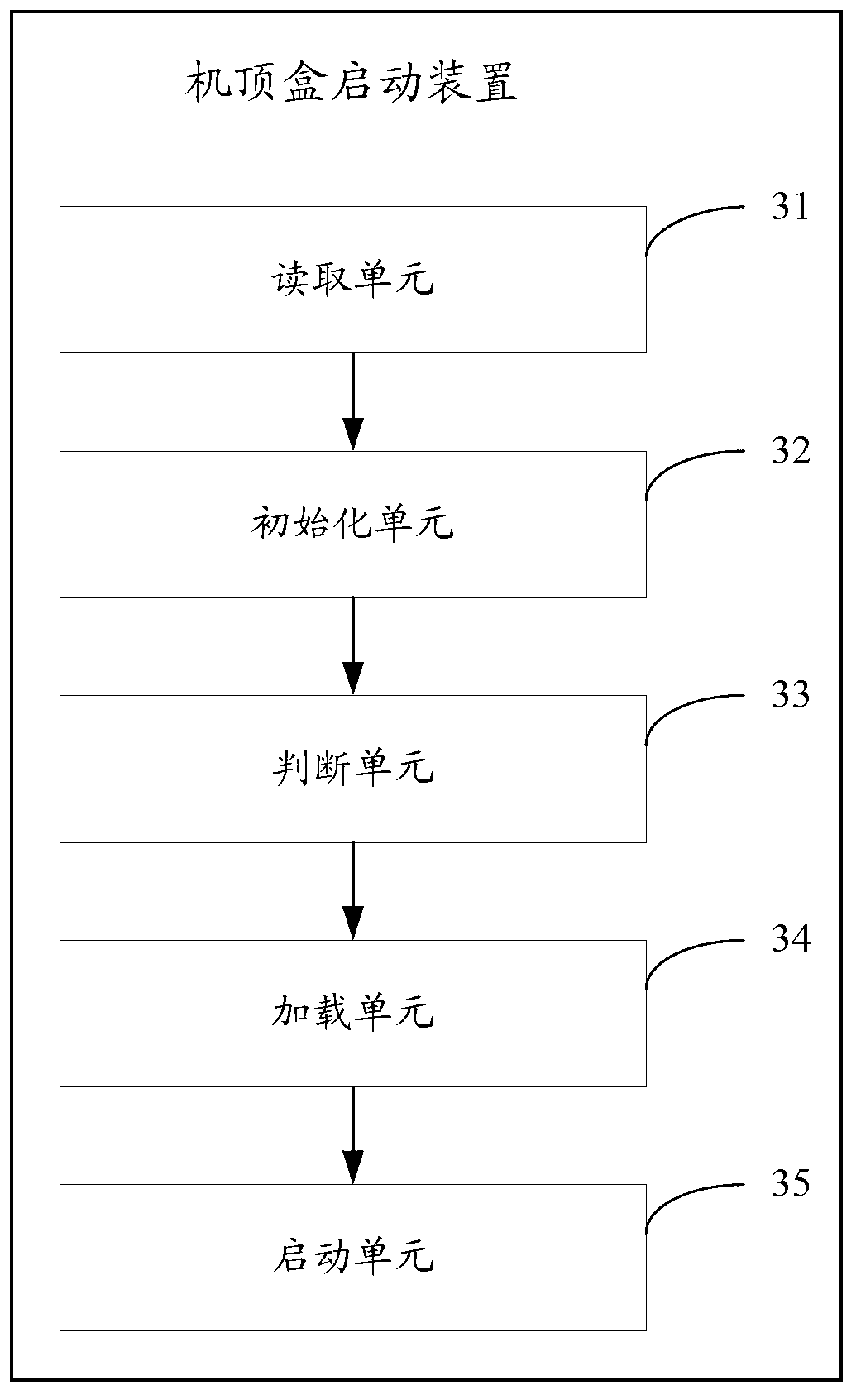

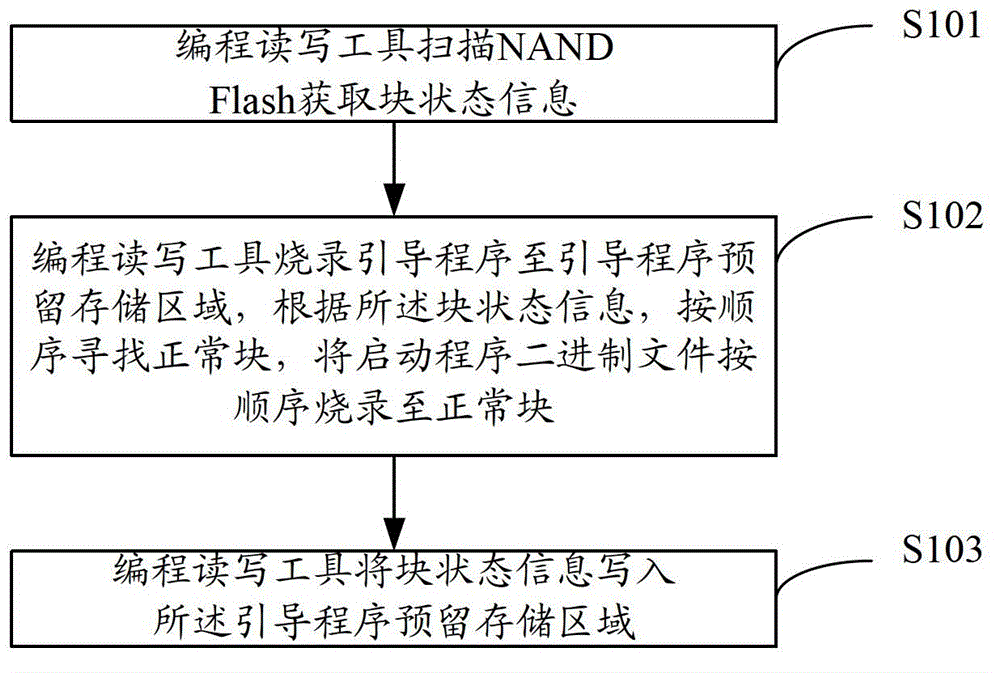

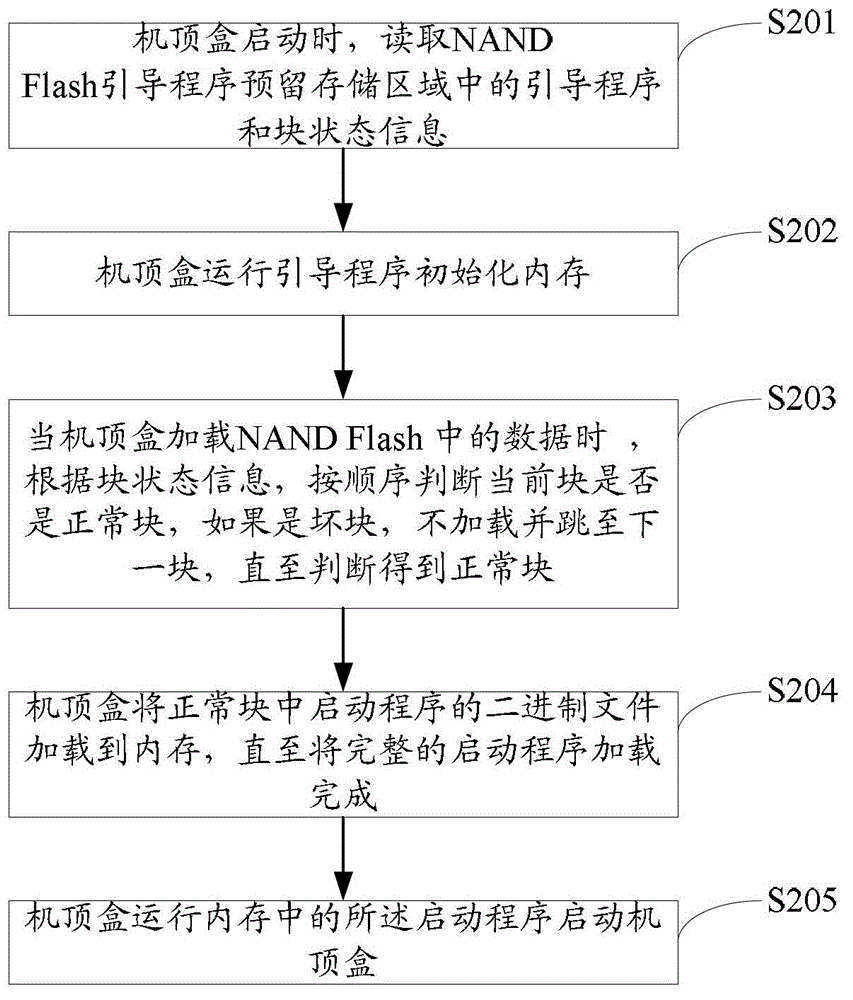

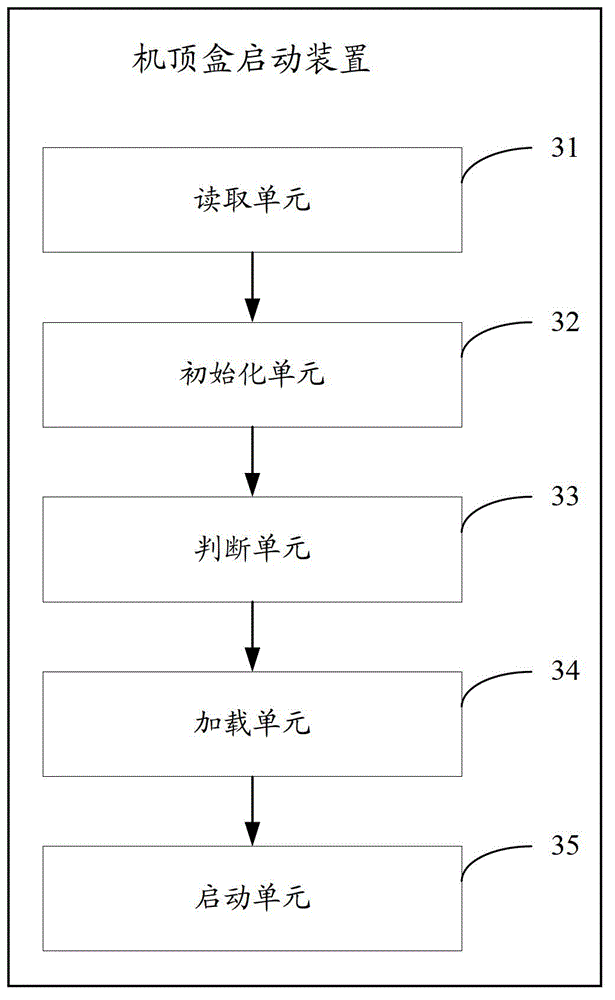

STB (Set Top Box) starting method and device

InactiveCN102883220ASolve the crash problemFull boot programSelective content distributionComputer scienceBooting

The invention is applicable to the technical field of a STB (Set Top Box) and provides a STB starting method and a STB starting device. The method comprises the following steps of: when the STB is started, a bootstrapper and block state information in an NAND Flash bootstrapper preserved storage region are read; the STB operates a bootstrapper initialization memory; when data in a NAND Flash is loaded into the STB, the STB loads a binary file of an initiator in a normal block into the memory until completing loading the complete initiator; and the STB operates the initiator in the memory to be started. According to the invention, the initiator is written into the normal block by acquiring the block state information in the process of burning the NAND Flash and storing the block state information into the NAND Flash; and when the STB is started, the block state information is read, the initiator in the normal block is loaded into the memory and the initiator is executed to start the STB, so that the problem of crash in the starting process, which is caused by the case that data of a bad block is possibly loaded when the bootstrapper loads initiators of more than one block, is solved.

Owner:SHENZHEN JIUZHOU ELECTRIC

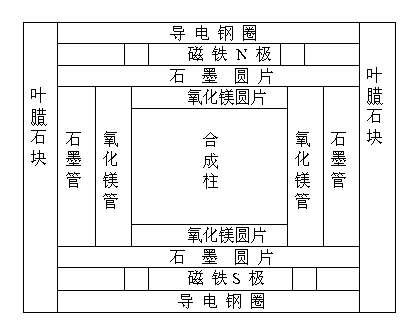

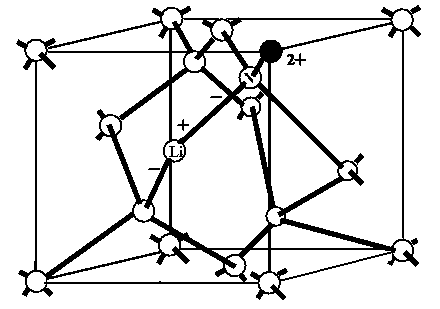

N-type diamond semiconductor monocrystal and production method thereof

ActiveCN103103609AImprove thermal conductivityImprove cooling effectPolycrystalline material growthUltra-high pressure processesOctahedronElectrolysis

The invention relates to an N-type diamond semiconductor monocrystal and a production method thereof. The crystal contains nitrogen ions, lithium ions and beryllium ions regularly arrayed in the crystal, wherein the total content of nitrogen-lithium atom pairs, nitrogen-beryllium atom pairs and lithium-nitrogen-beryllium atom pairs is 100-10000ppm, the size of the semiconductor monocrystal is 0.3-10mm, and the crystal is a regular hexahedron, a regular octahedron or a hexahedron-octahedron. The production method comprises the following steps of: mixing graphite powder, a metal catalyst, lithium nitride and beryllium nitride in proportion, pressurizing to 100-300MPa to carry out cold isostatic pressing treatment, relieving the pressure, then breaking the mixed materials, placing the broken mixed materials into a mold to press to form columnar synthetic columns, sintering in vacuum, filling synthetic blocks, and processing in a high-temperature high-pressure oriented magnetic field; breaking the synthetic columns, performing electrolysis and separating by using a shaker to obtain the N-type diamond semiconductor monocrystal. The monocrystal provided by the invention is good in conductivity, high in optical-to-thermal energy conversion efficiency, suitable for manufacturing solar batteries, LED (Light Emitting Diode) sources and high-performance chips, and stable in performance.

Owner:焦作天宝桓祥机械科技有限公司

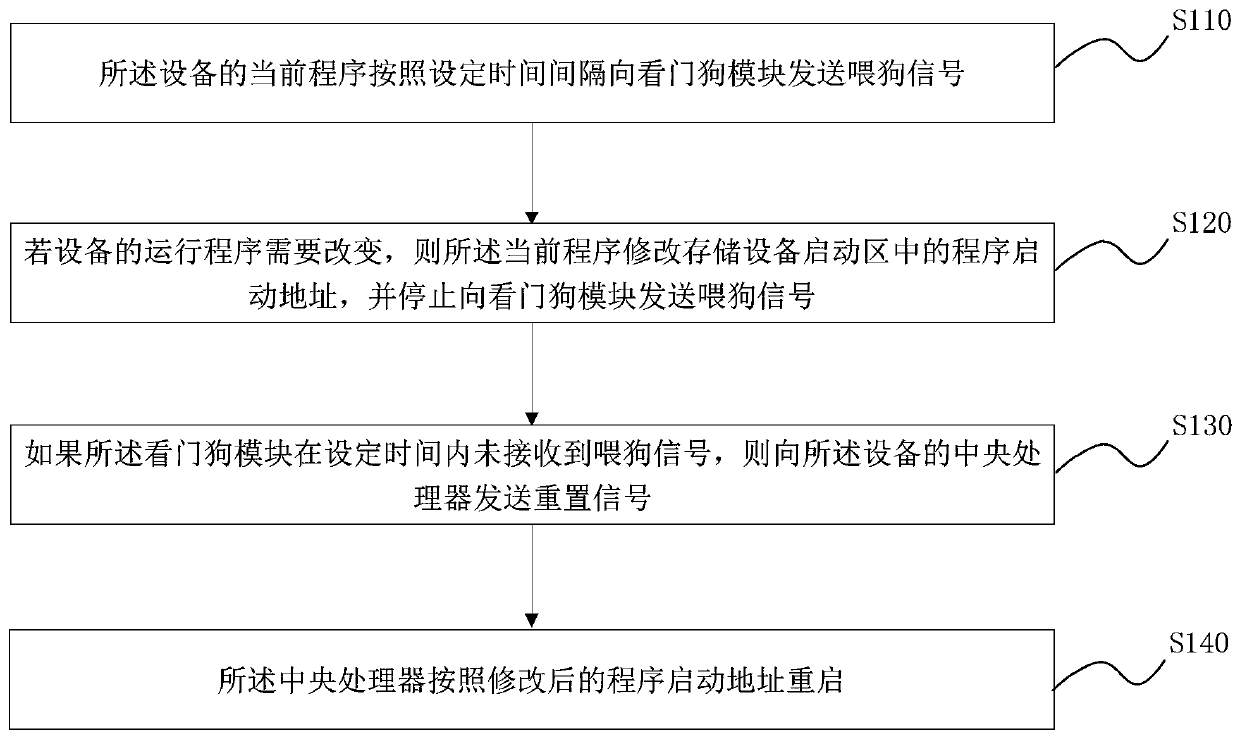

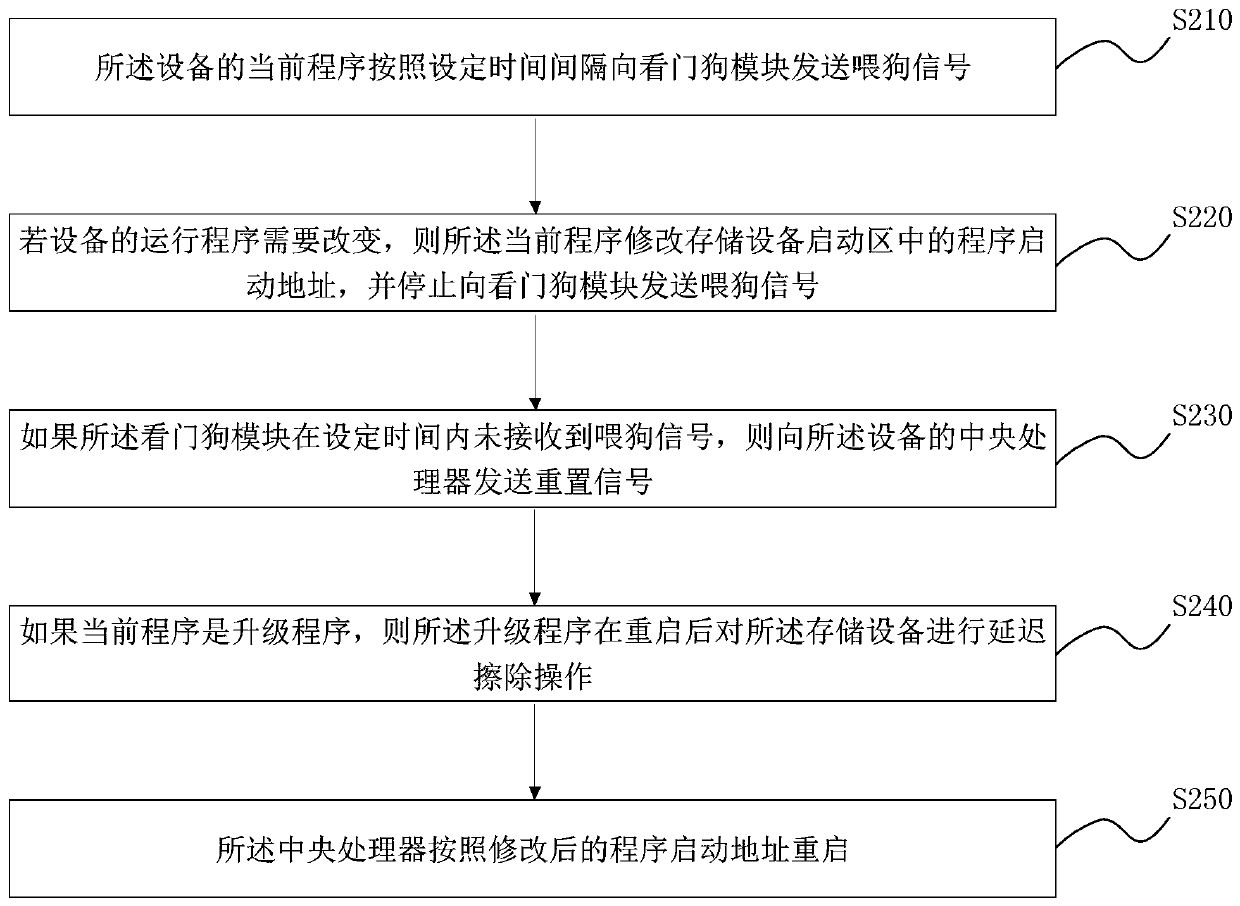

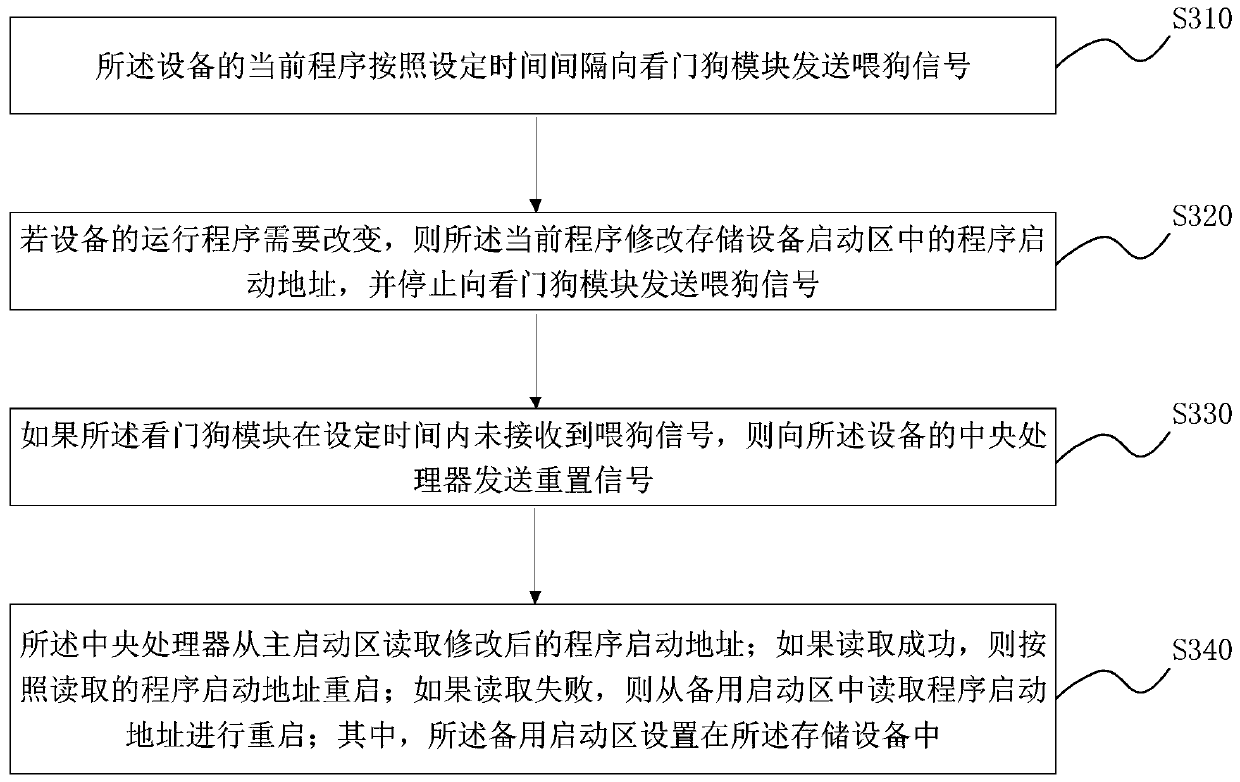

Equipment application program updating method and device, equipment and storage medium

PendingCN110502267AAvoid Power Outage SituationsSolve the crash problemSoftware deploymentOff timeElectricity

The embodiment of the invention discloses an equipment application program updating method and device, equipment and a storage medium. The method comprises: a current program of the equipment sendinga dog feeding signal to a watchdog module according to a set time interval; if the running program of the equipment needs to be changed, the current program modifying the program starting address in the starting area of the storage equipment and stopping sending the dog feeding signal to the watchdog module; if the watchdog module does not receive the dog feeding signal within the set time, sending a reset signal to a central processing unit of the equipment; and restarting the central processing unit according to the modified program starting address. According to the embodiment of the invention, the watchdog module acquires the accurate power-off time point according to the process of the upgrading program; and the equipment is automatically powered off and powered on, so that the situation that the power-off operation is carried out without modifying the starting address is avoided, and the problem that the equipment crashes due to the fact that the power-off operation is carried out without modifying the starting address during upgrading of the equipment is solved.

Owner:BEIJING AUTOROAD TECH CO LTD

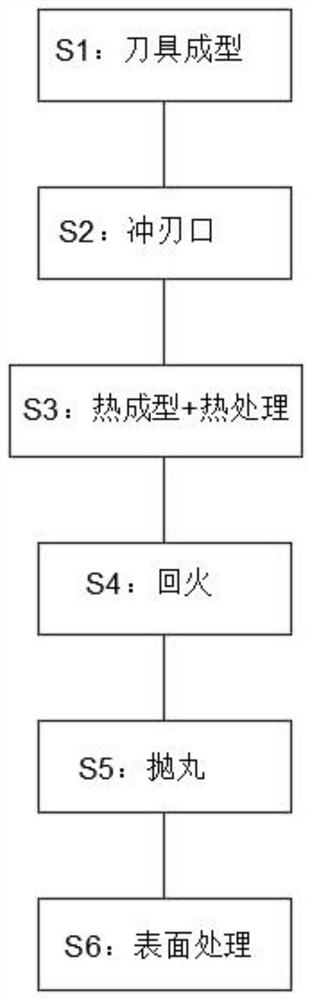

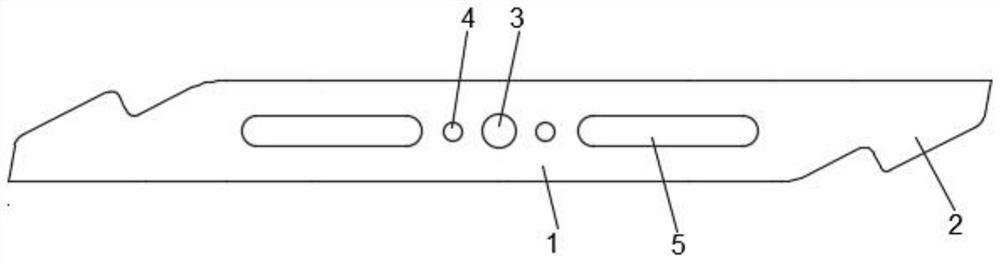

Machining method of high-strength handheld mower blade

ActiveCN113427203ASolve the crash problemSolve the problem of heat treatment deformationMowersFurnace typesMolten stateTempering

The invention relates to the technical field of hay mower blade machining, and discloses a machining method of a high-strength handheld hay mower blade. The machining method comprises the following steps: S1, cutter forming is carried out, molten steel in a molten state is injected into a mold, and cooling is carried out after the blade is formed; S2, cutting edge punching is carried out, and the cutting edge position is continuously punched multiple times; S3, thermal forming and heat treatment are carried out, specifically, a cutter is put into a heating furnace at the temperature of 1000 DEG C to be subjected to thermal forging forming, isothermal quenching is carried out for 10 minutes, and the hardness of the quenched blade is 40-45 HRC; S4, tempering is conducted, the temperature in the heating furnace is reduced to 500 DEG C at the speed of reducing 100 DEG C per minute, and tempering is conducted for 30 minutes at the temperature of 500 DEG C; S5, shot blasting is conducted, the cutter is put into a shot blasting machine to be subjected to surface polishing for 2 minutes; and S6, surface treatment is conducted, and the cutter is put into an electrophoresis device to be subjected to black electrophoresis. The problem of cutting edge breakage can be solved, the cutting edge strength is high, the process steps are shortened, the machining efficiency is improved, and the manufacturing cost is low.

Owner:安徽博行机械有限公司

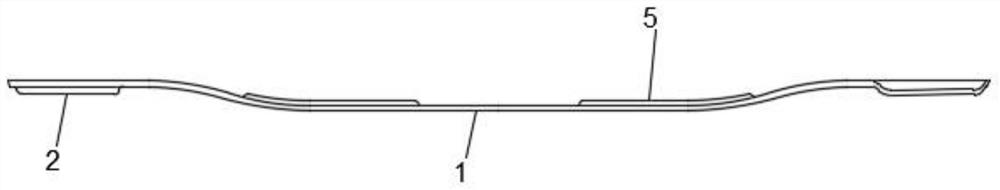

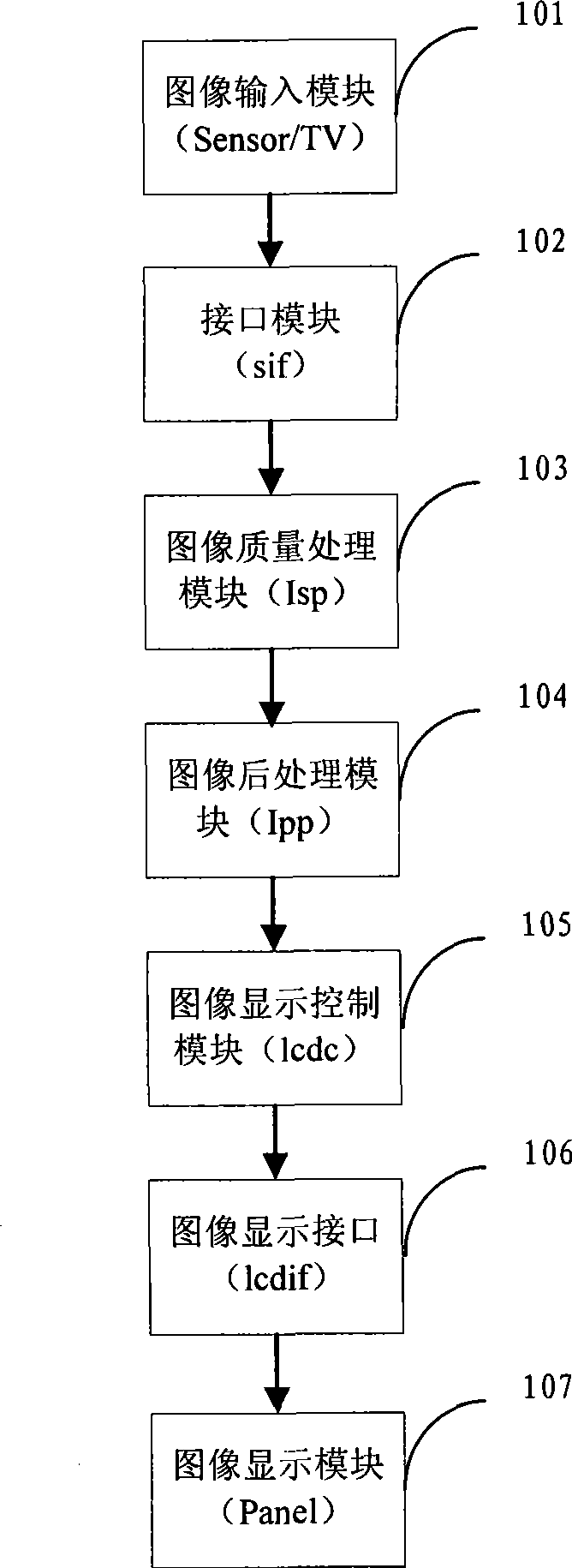

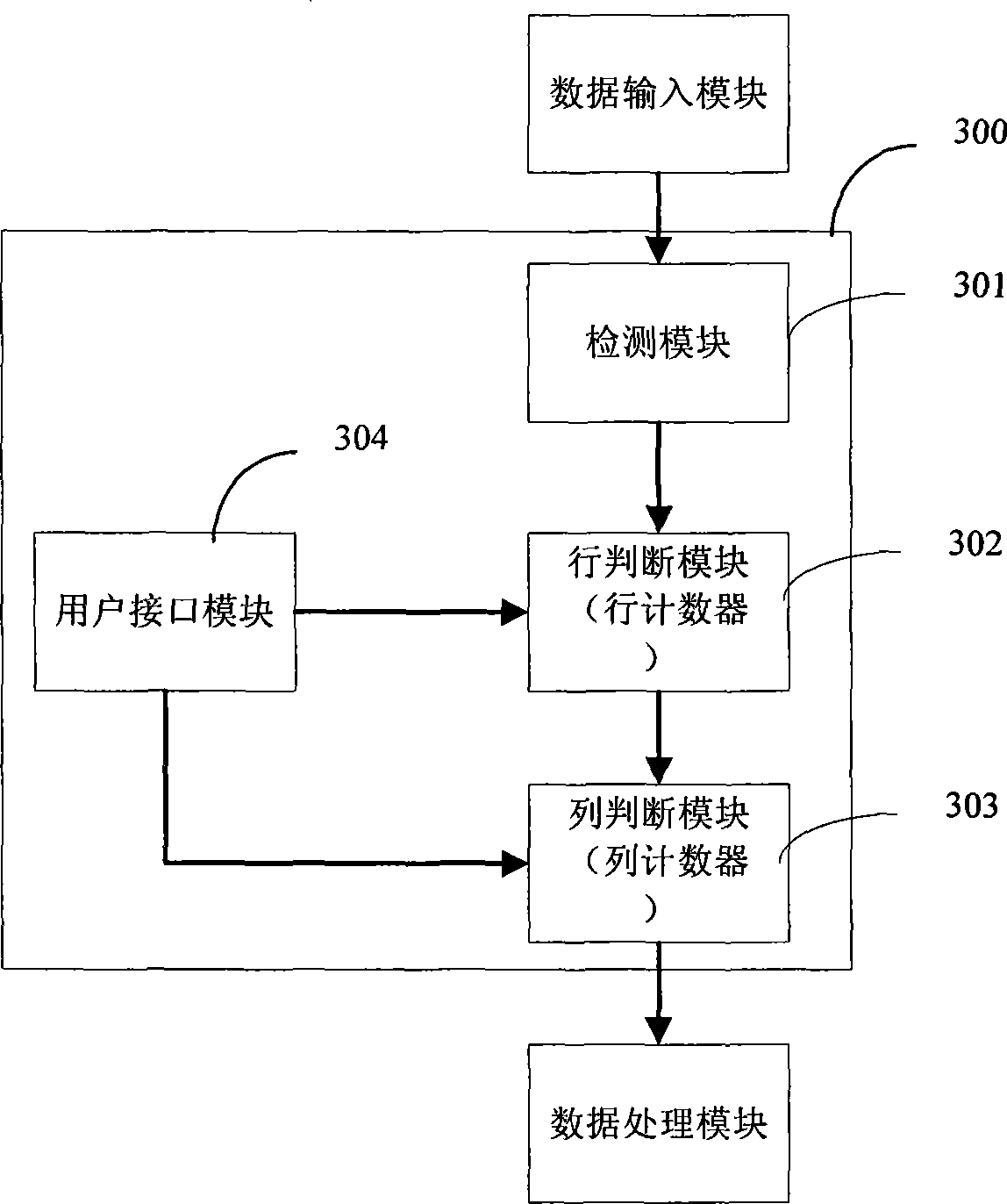

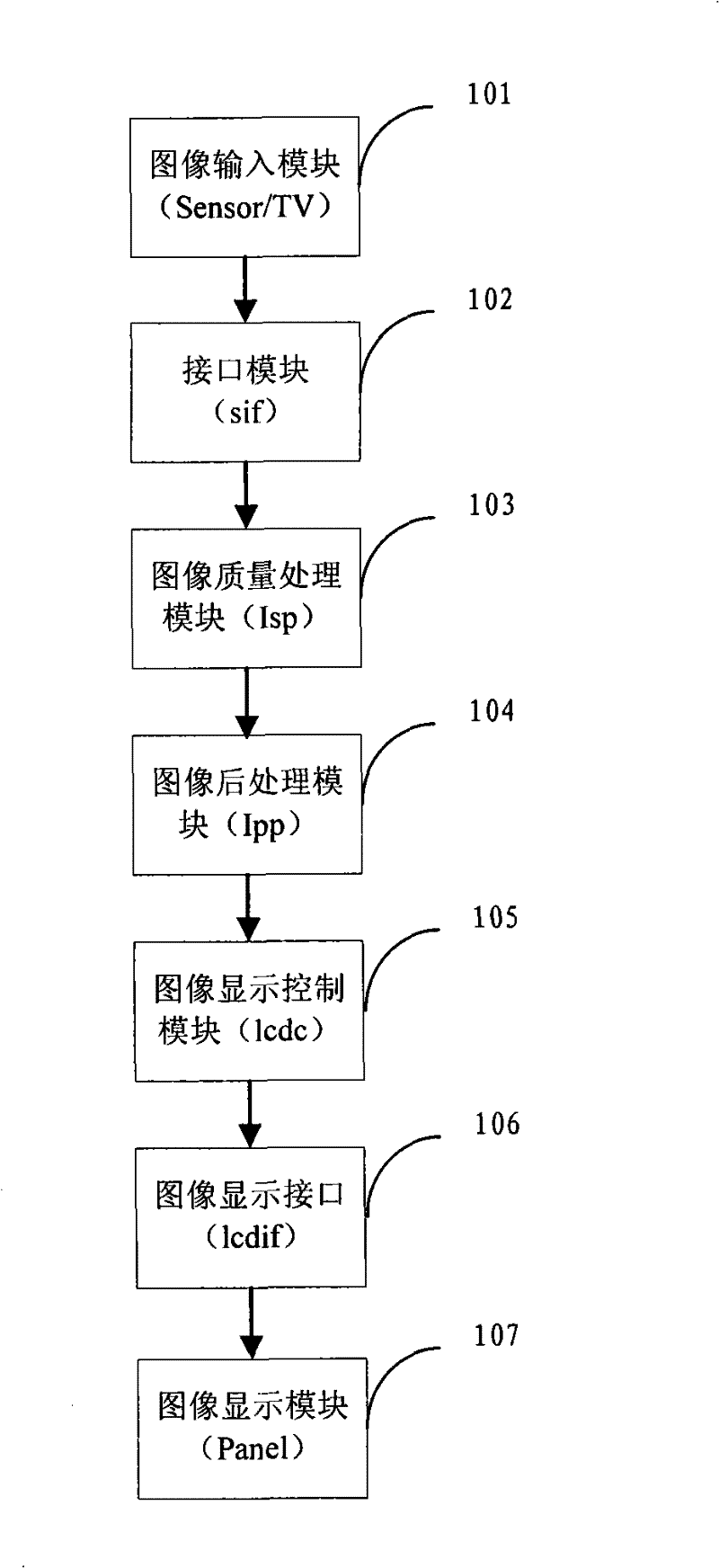

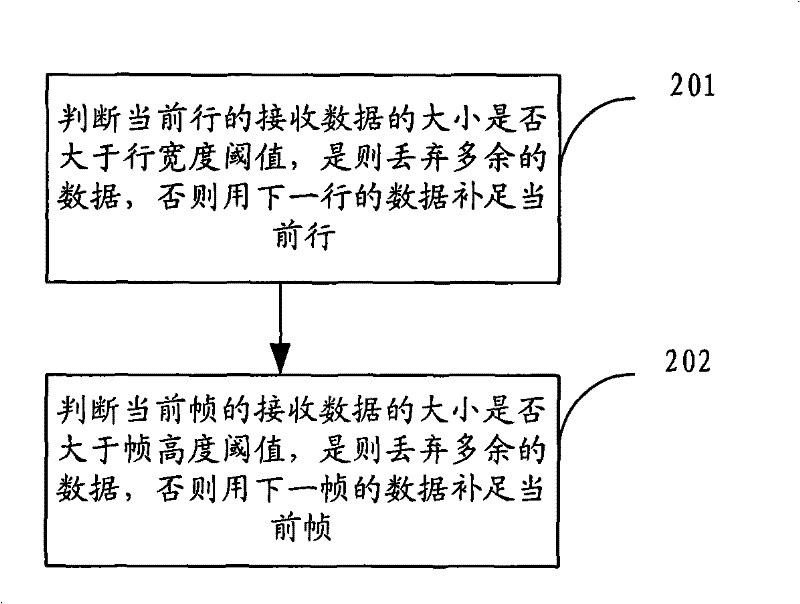

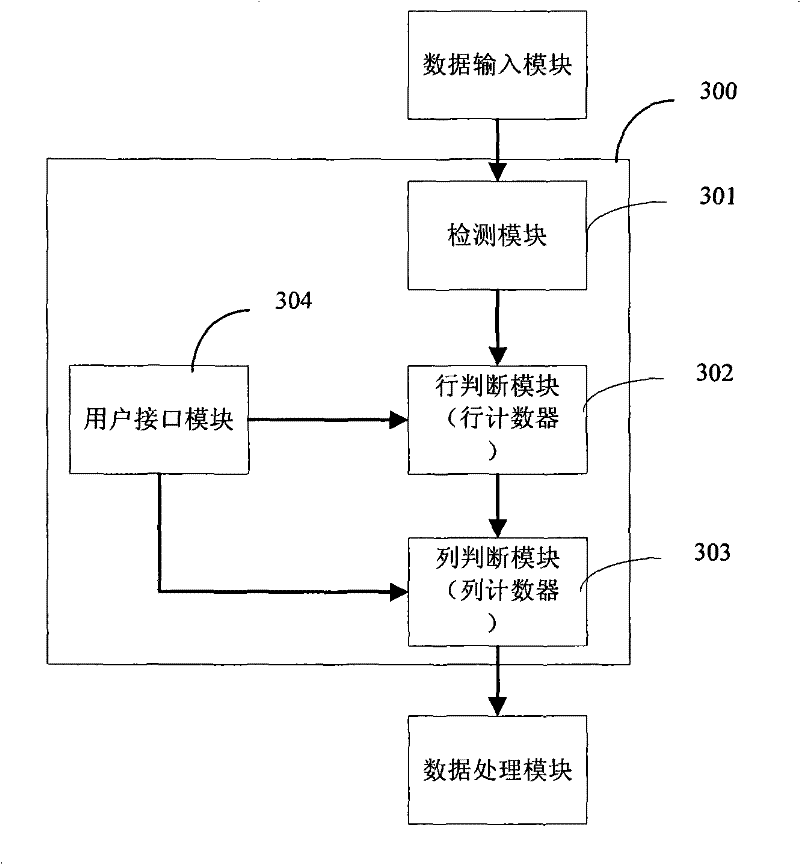

Method and apparatus for correcting data error in image processing system

InactiveCN101511029ACrash will notSolve the crash problemClosed circuit television systemsDigital video signal modificationCorrection methodData error

The invention provides a data error correction method for image processing systems and a device thereof, and the method comprises a row judgment step and a column judgment step. The row judgment step: whether the receiving data size of the current row is larger than the threshold of the row width is judged, if so, redundant data is dropped, otherwise the data of the next row is adopted to make up the current row; the column judgment step: whether the receiving data size of the current frame is larger than the threshold of the frame height is judged, if so, redundant data is dropped, otherwise the data of the next column is adopted to make up the current frame. The method has an advantage that dead halt or other abnormal conditions of the system caused by row data deficiency or frame data deficiency can be prevented.

Owner:WUXI ZGMICRO ELECTRONICS CO LTD

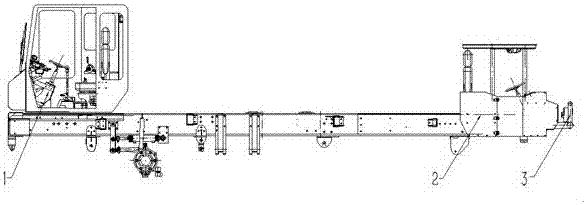

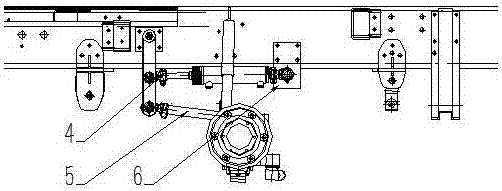

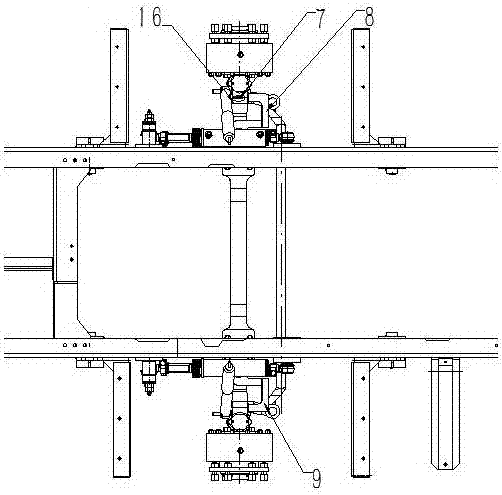

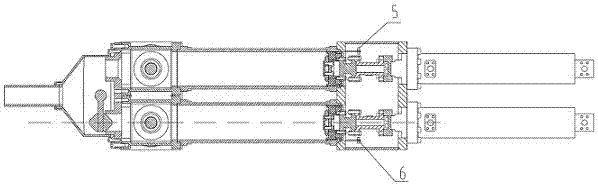

Double-driving system of concrete mixer carrier vehicle

ActiveCN107284337AEnsure safetyGuaranteed independenceConcrete transportationSteering wheelVehicle frame

The invention relates to a double-driving system of a concrete mixer carrier vehicle The double-driving system of the concrete mixer carrier vehicle comprises a vehicle frame; a front steering assembly is arranged in front side of the vehicle frame; a steering execution assembly is arranged under the vehicle frame; a back driving assembly is arranged on the back side of the vehicle frame; the back driving assembly is arranged inside a back cab; the front steering assembly comprises a front steering wheel, a first front steering support, a second front steering support and a full hydraulic pressure steering device; the steering execution assembly comprises a steering power cylinder assembly with a connector, a steering transverse pull rod assembly, an oil cylinder seat, a right bending arm, a left bending arm, a rocking arm seat, a rocking arm, a copper sleeve and a straight-through type pressure injection oil cup; the back driving assembly comprises an expanded cab, an auxiliary support seat, a fixing frame, a pedal fixing seat, a cab bottom plate and a chair seat. The double-driving system of the concrete mixer carrier vehicle realizes two-direction driving through switching between front driving and back driving, solves a problem that the vehicle is hard to turn around in a narrow roadway, solves a problem that vehicle collision happens due to a poor reversing vision and improves a phenomenon that original mechanical steering is labor-consuming.

Owner:LAIZHOU YATONG HEAVY EQUIP

Tablet computer with good heat dissipation

InactiveCN106547322ASolve the crash problemSolve the problem of body burnoutDigital data processing detailsTablet computerElectricity

The invention relates to the field of electronic products, and particularly relates to a tablet computer with good heat dissipation. The invention is aimed at providing a tablet computer for efficiently dissipating heat via a comprehensive heat dissipation structure, thus solving the problem of crash or burnout due to too high temperature of the tablet computer. According to the technical solution, the tablet computer with good heat dissipation comprises a shell, a heat sink strip is arranged on the shell, a plurality of radiating ribs are arranged on the heat sink strip, a heat dissipation air duct is arranged in the heat sink strip, one end of the heat sink strip is connected with a heat dissipation fan, the air outlet of the heat dissipation fan is communicated with the heat dissipation air duct, and the heat dissipation fan is electrically connected with a power line of the tablet computer; and the shell is also provided with a plurality of heat dissipation holes. The invention is applicable to a tablet computer with good heat dissipation.

Owner:CHENGDU YANXINGGUO TECH CO LTD

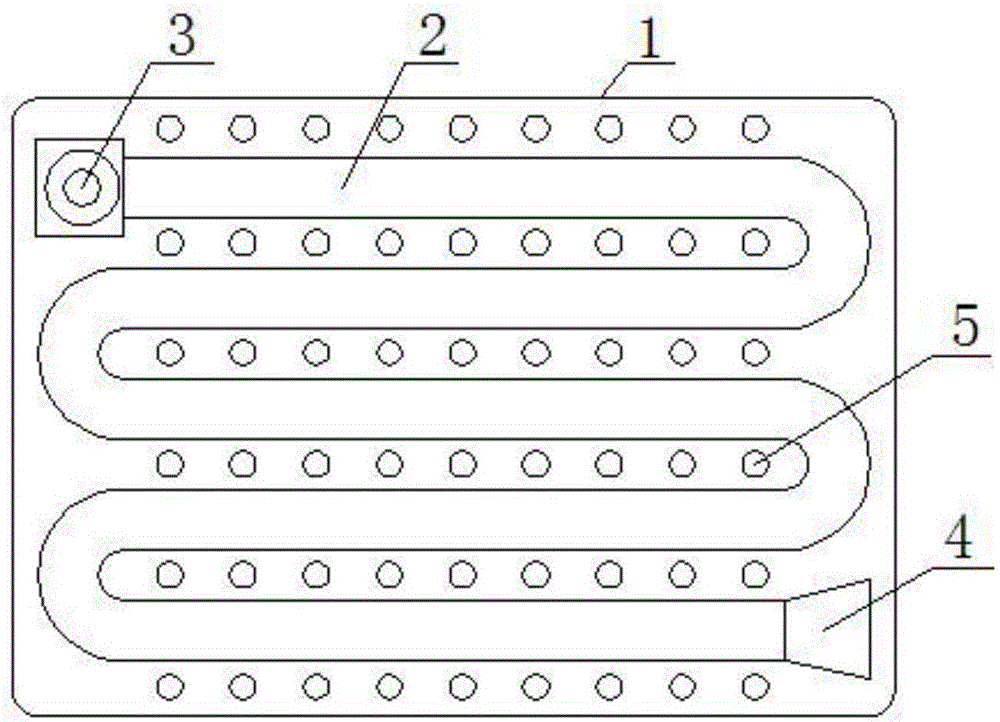

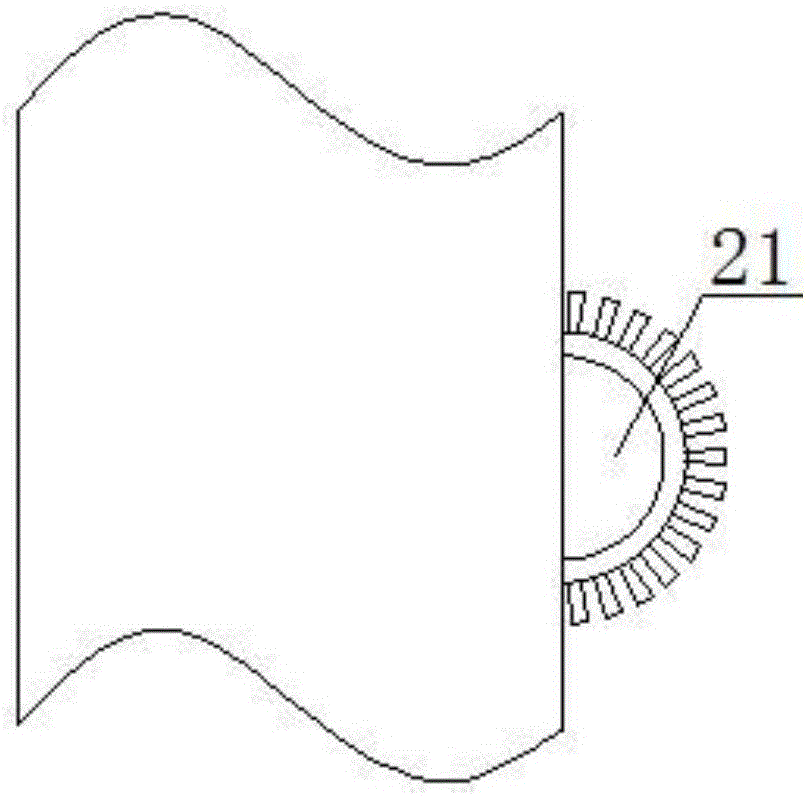

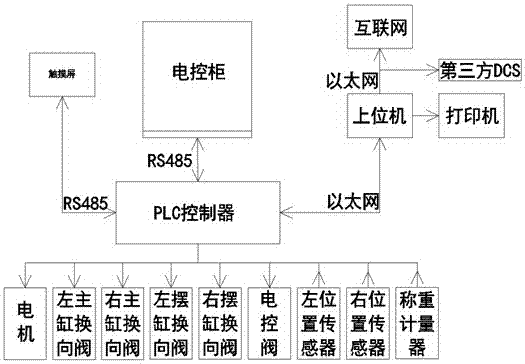

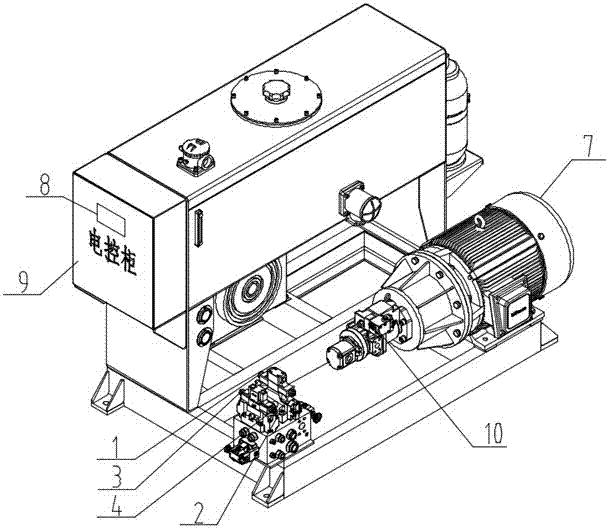

Electrical self-control system of sludge pumping device

InactiveCN108005891AEasy to installLess control wiringPump controlPositive-displacement liquid enginesSludgeMaster cylinder

The invention discloses an electrical self-control system of a sludge pumping device. The electrical self-control system comprises a left main cylinder reversing valve, a right main cylinder reversingvalve, a left swing cylinder reversing valve, a right swing cylinder reversing valve, a left position sensor, a right position sensor signal, a motor, a touch screen, an electric control cabinet, a hydraulic-control valve / electric-control valve and a PLC controller, wherein the hydraulic-control valve / electric-control valve is arranged at the front end of the motor; the left main cylinder reversing valve and the right main cylinder reversing valve are arranged at the two ends of a main cylinder valve block of a sludge pump; the left swing cylinder reversing valve and the right swing cylinderreversing valve are arranged at the two ends of a swing cylinder valve block of the sludge pump; the left position sensor and the right position sensor signal are arranged at left and right sides of awater tank cover plate on the main cylinder end part of the sludge pump; the motor, the left main cylinder reversing valve, the right main cylinder reversing valve, the left swing cylinder reversingvalve, the right swing cylinder reversing valve, the hydraulic-control valve / electric-control valve, the left position sensor and the right position sensor signal are separately connected with the PLCcontroller; and the PLC controller is connected with the touch screen and the electric control cabinet. The electrical self-control system is high in safety, is simple in wiring, is complete in function, and is high in intelligent degree.

Owner:长沙紫宸科技开发有限公司

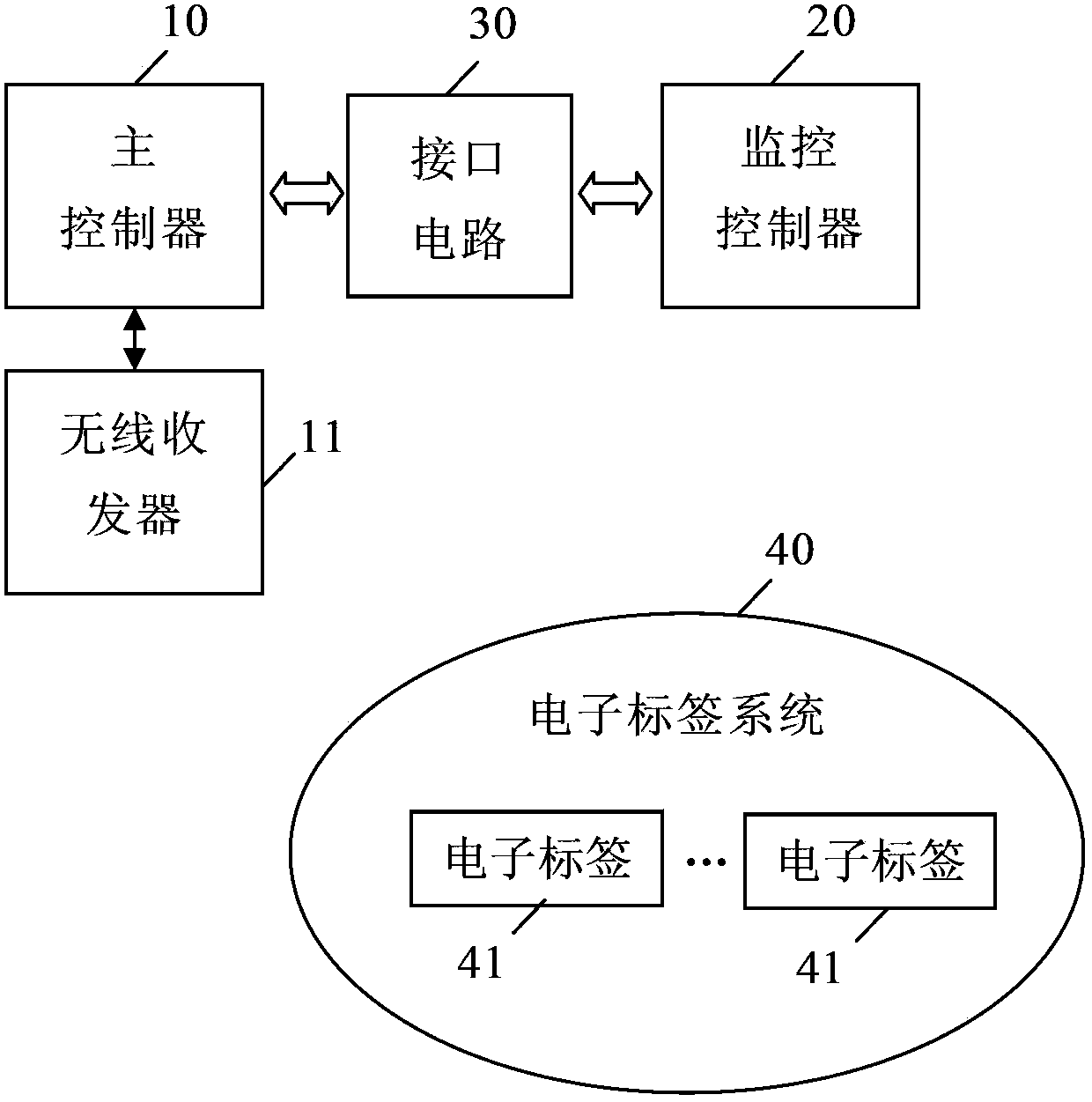

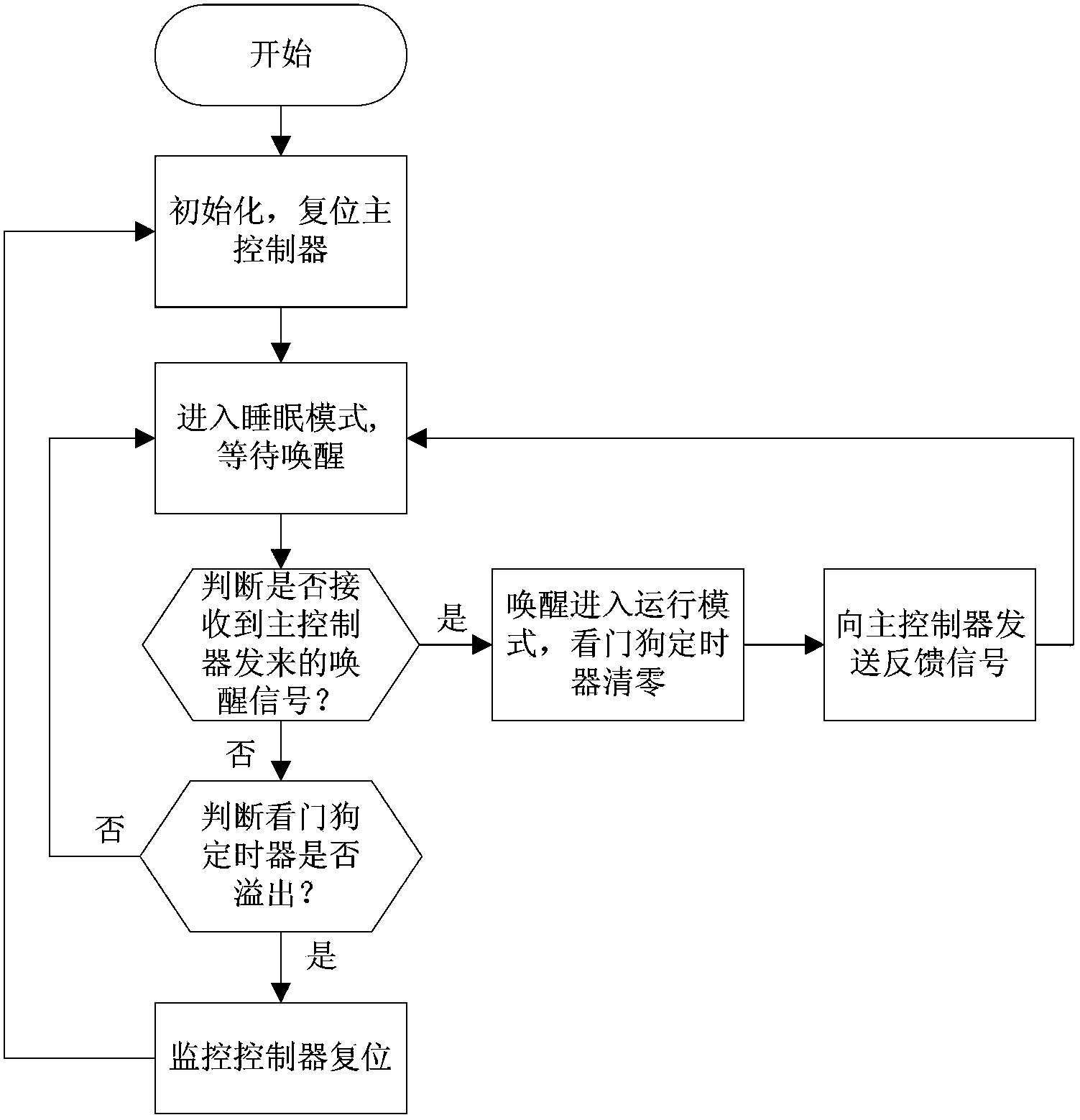

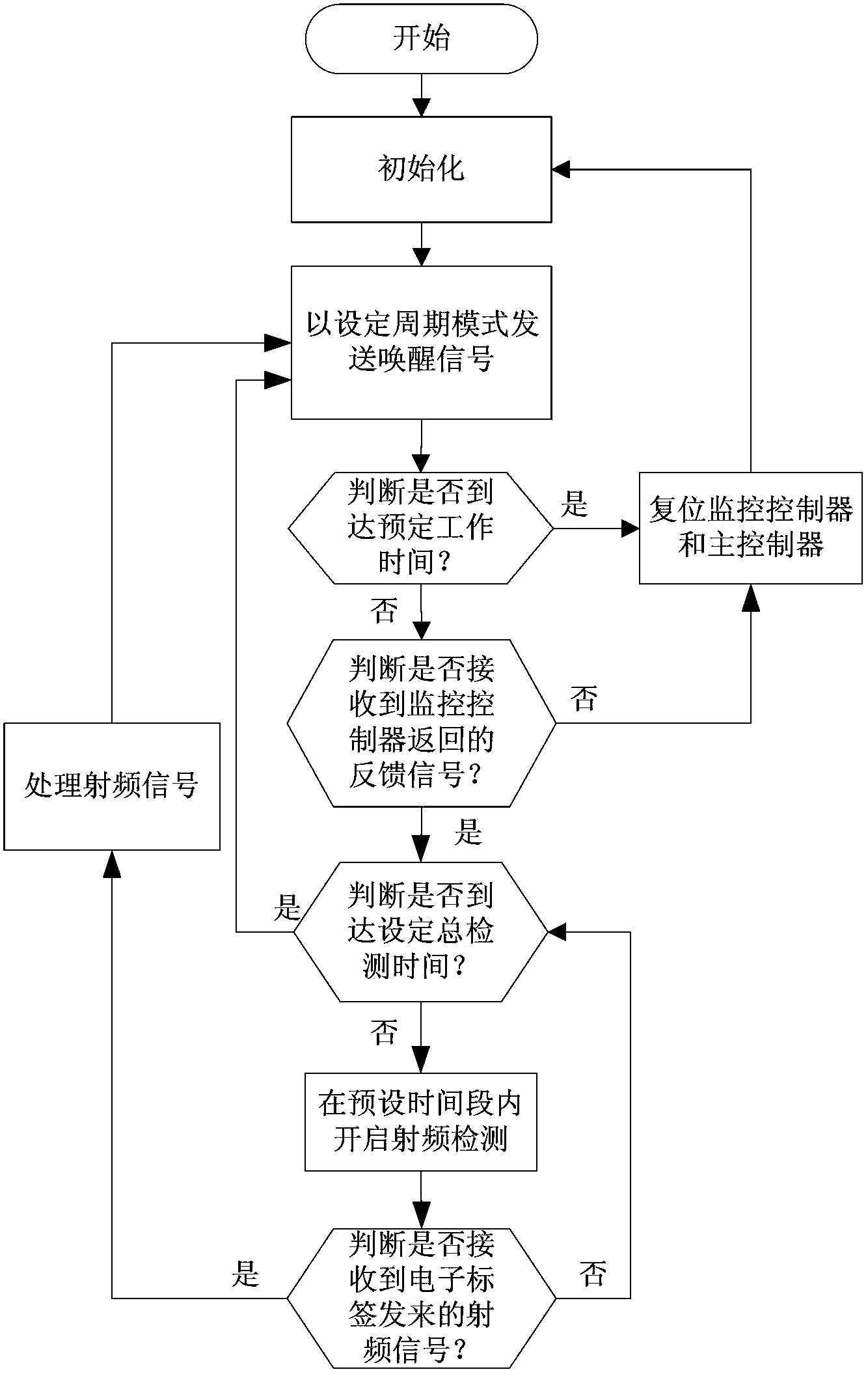

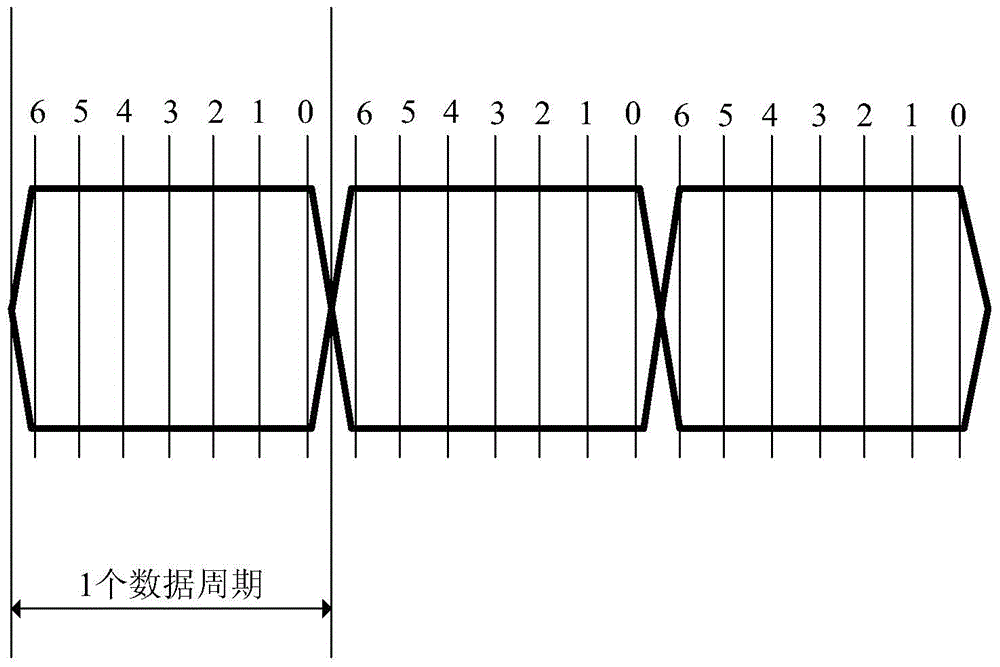

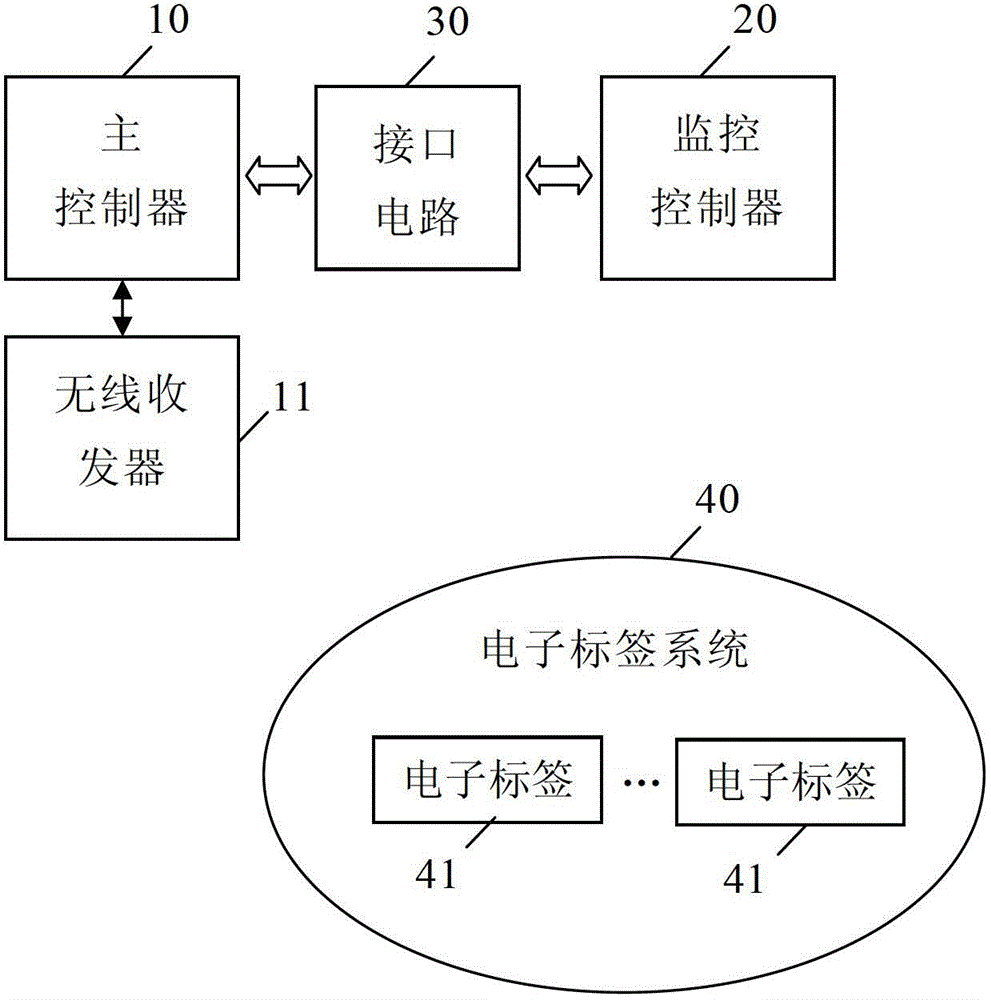

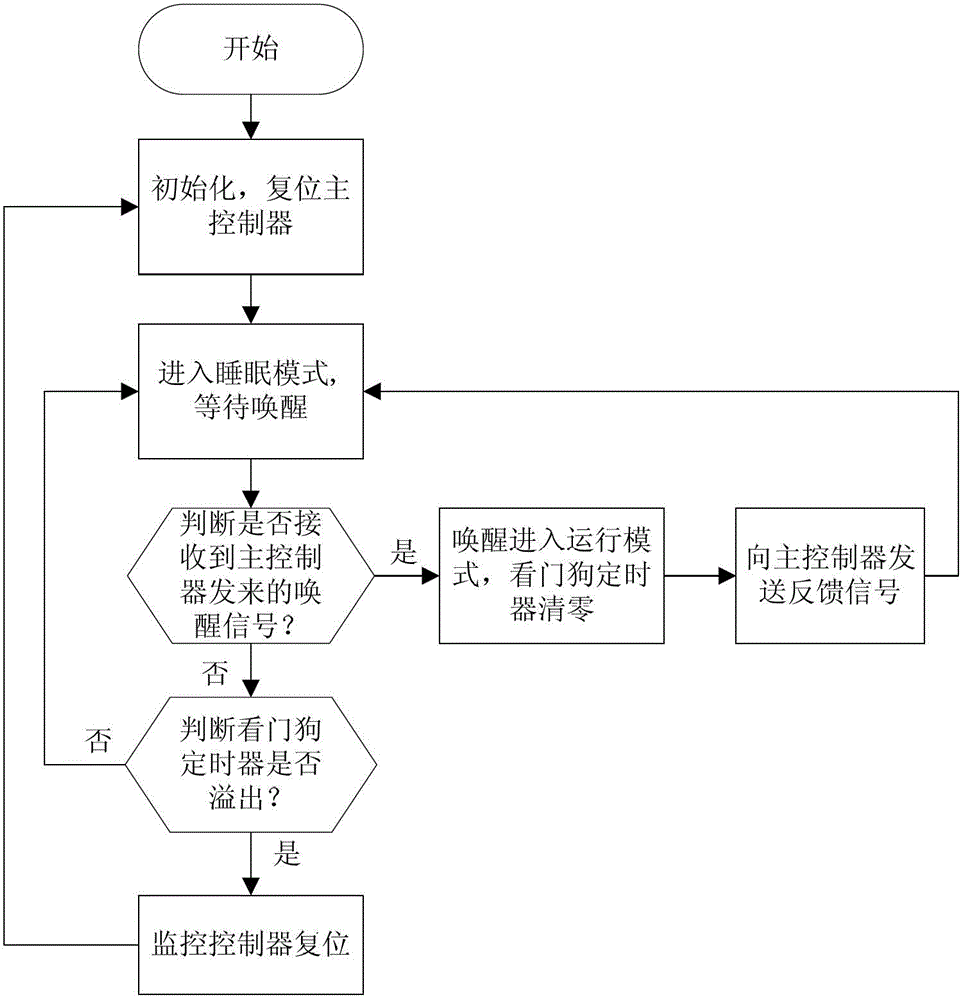

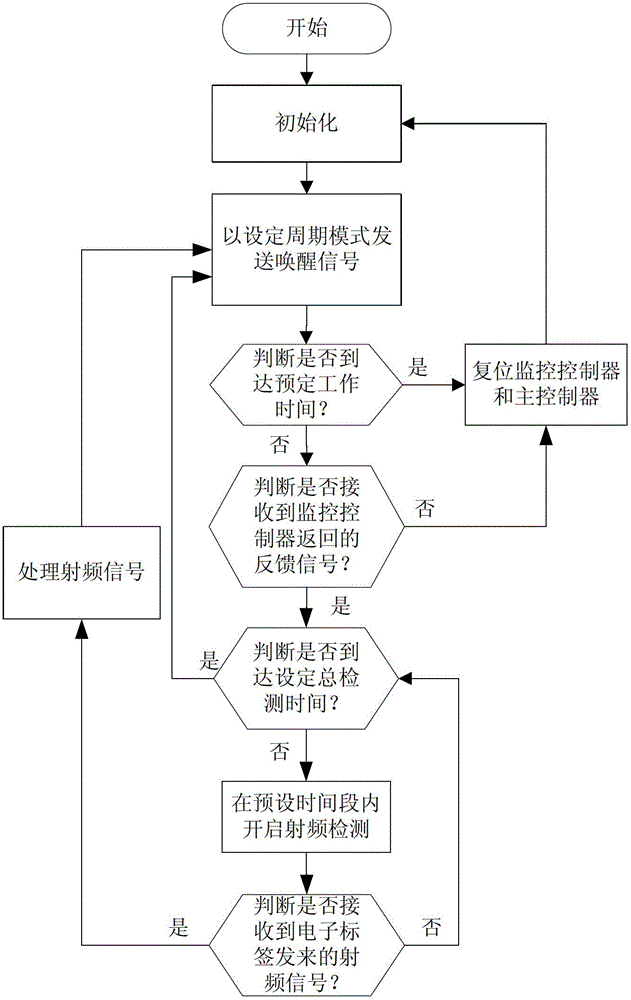

Dual-core work system and method for electronic tag system

ActiveCN103530271ALow costReduce power consumptionMultiple digital computer combinationsInterface circuitsTransceiver

The invention discloses a dual-core work system and method for an electronic tag system. The dual-core work system comprises a main controller and a monitoring controller. A corresponding IO interface of the main controller is connected with a corresponding IO interface of the monitoring controller through an interface circuit, and a wireless transceiver is internally or externally arranged on the main controller in a connecting mode. According to the dual-core work method, the work mode that the main controller and the monitoring controller are in mutual real-time monitoring and regular restoration is mainly used. The dual-core work system and method can meet the requirements for being strong interference resistance, low in cost, low in power consumption, capable of achieving monitoring in real time, and capable of completely solving the problem of dead halt and restoring regularly of the electronic tag system at present, and is particularly suitable for electronic tag systems under complex electromagnetic environments.

Owner:汉朗网络信息科技(北京)有限公司

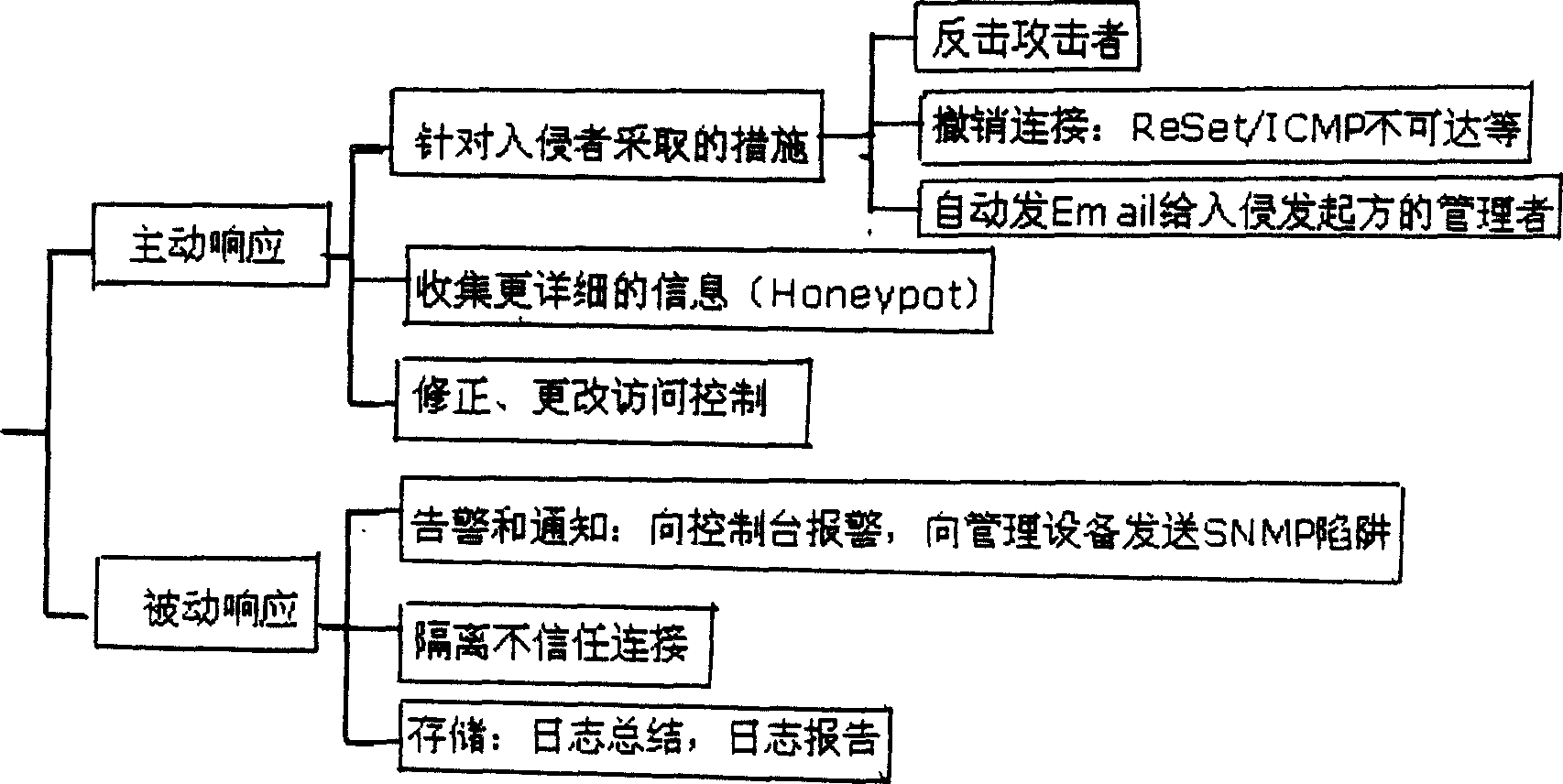

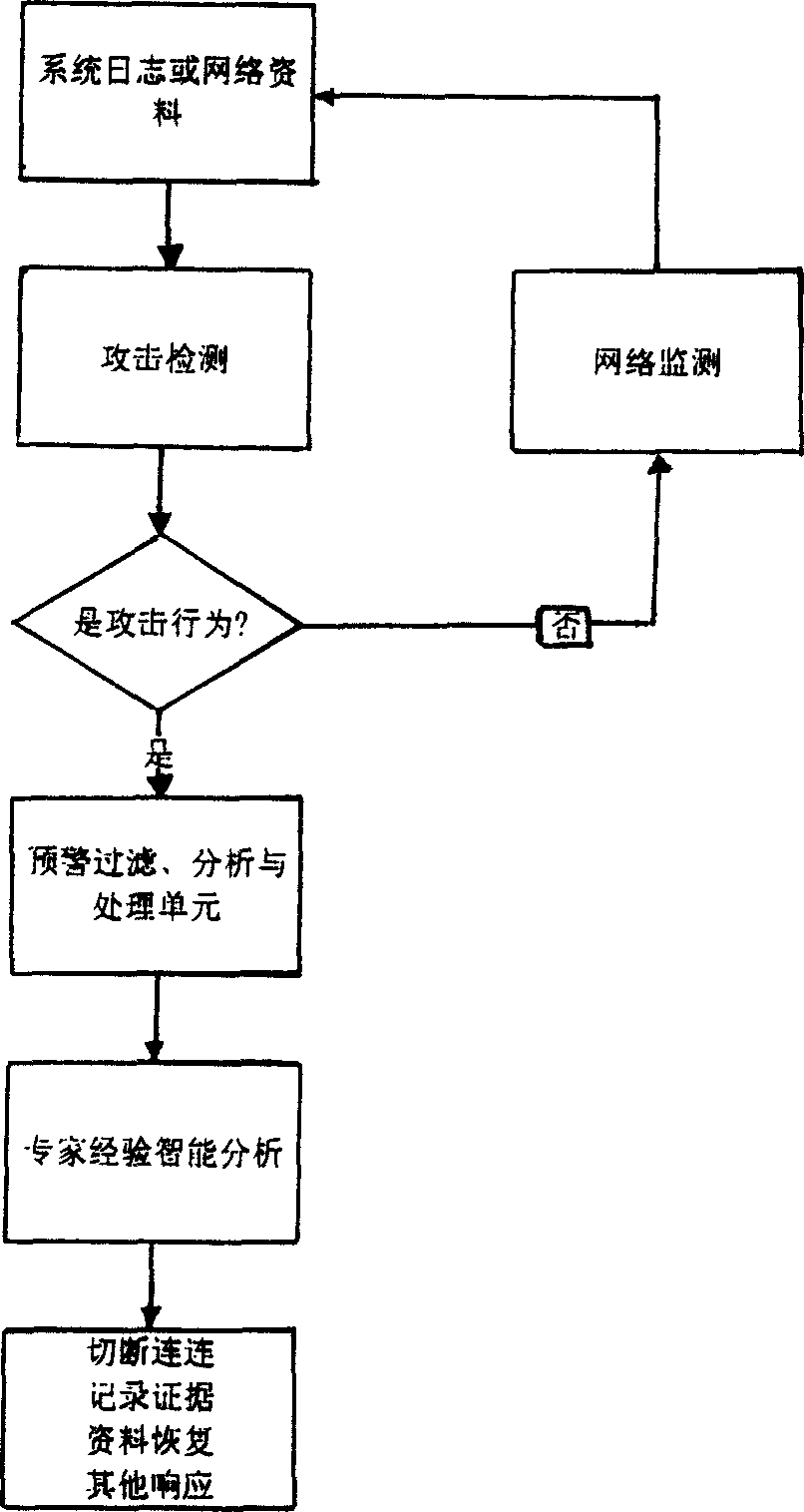

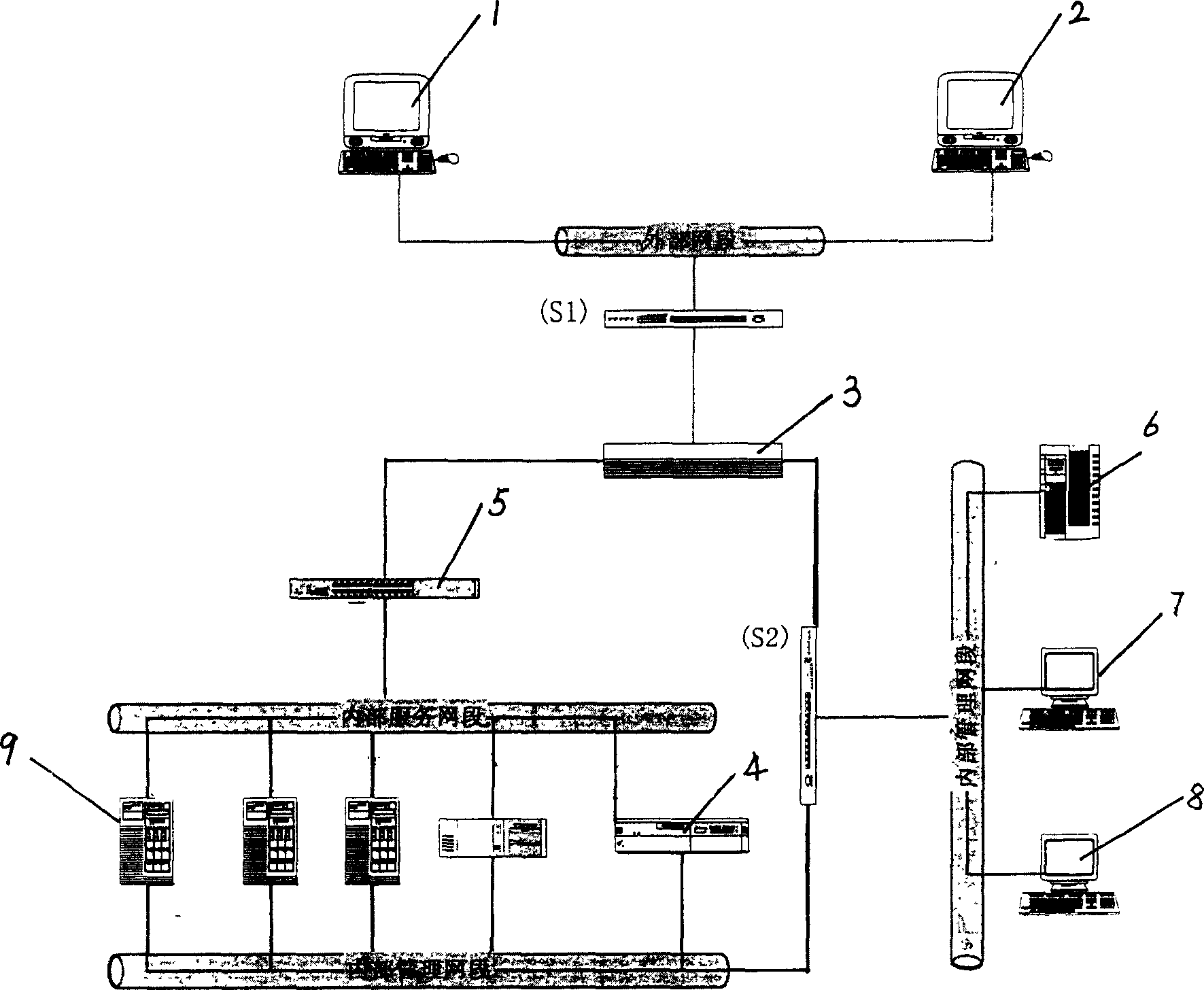

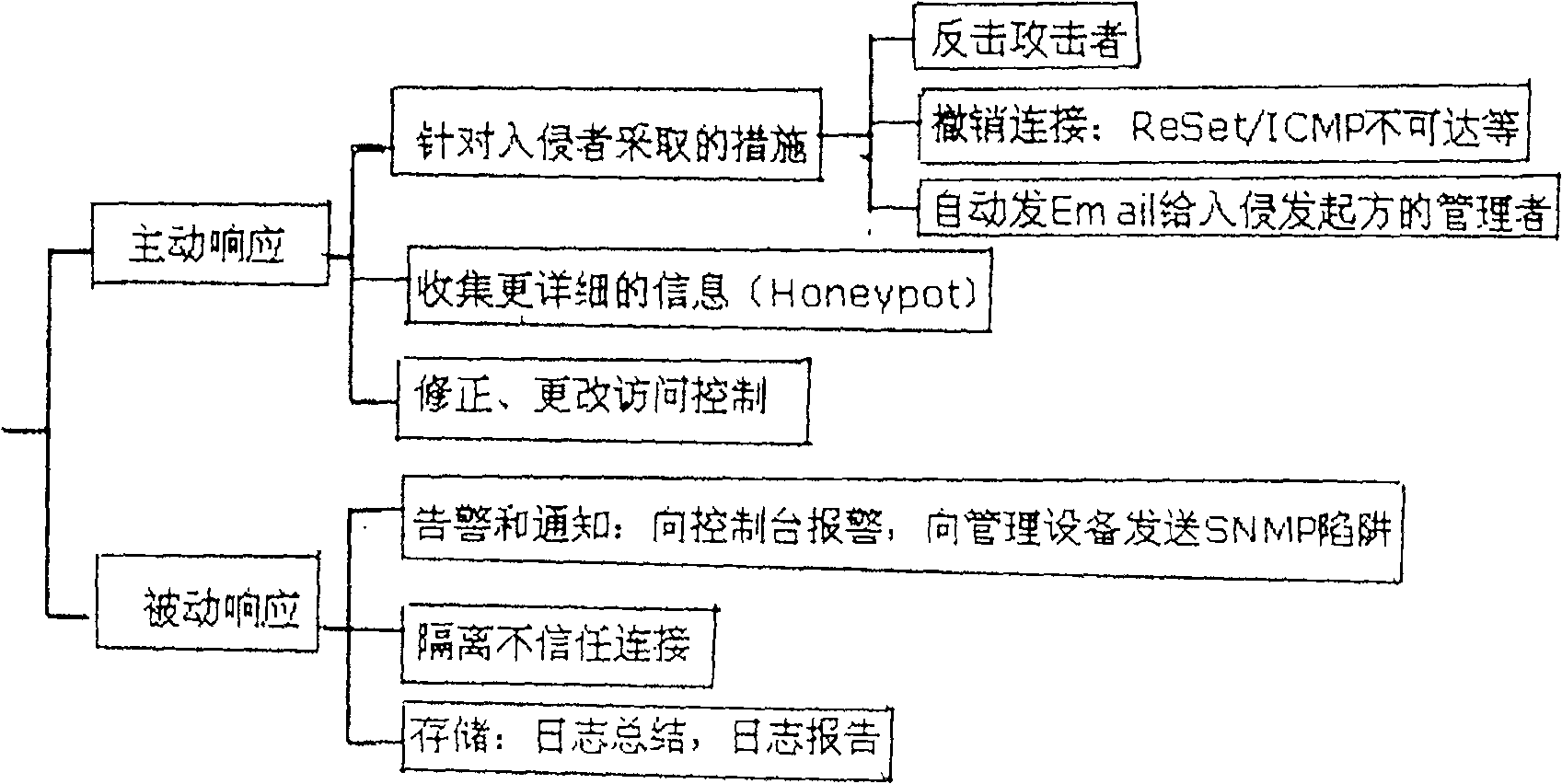

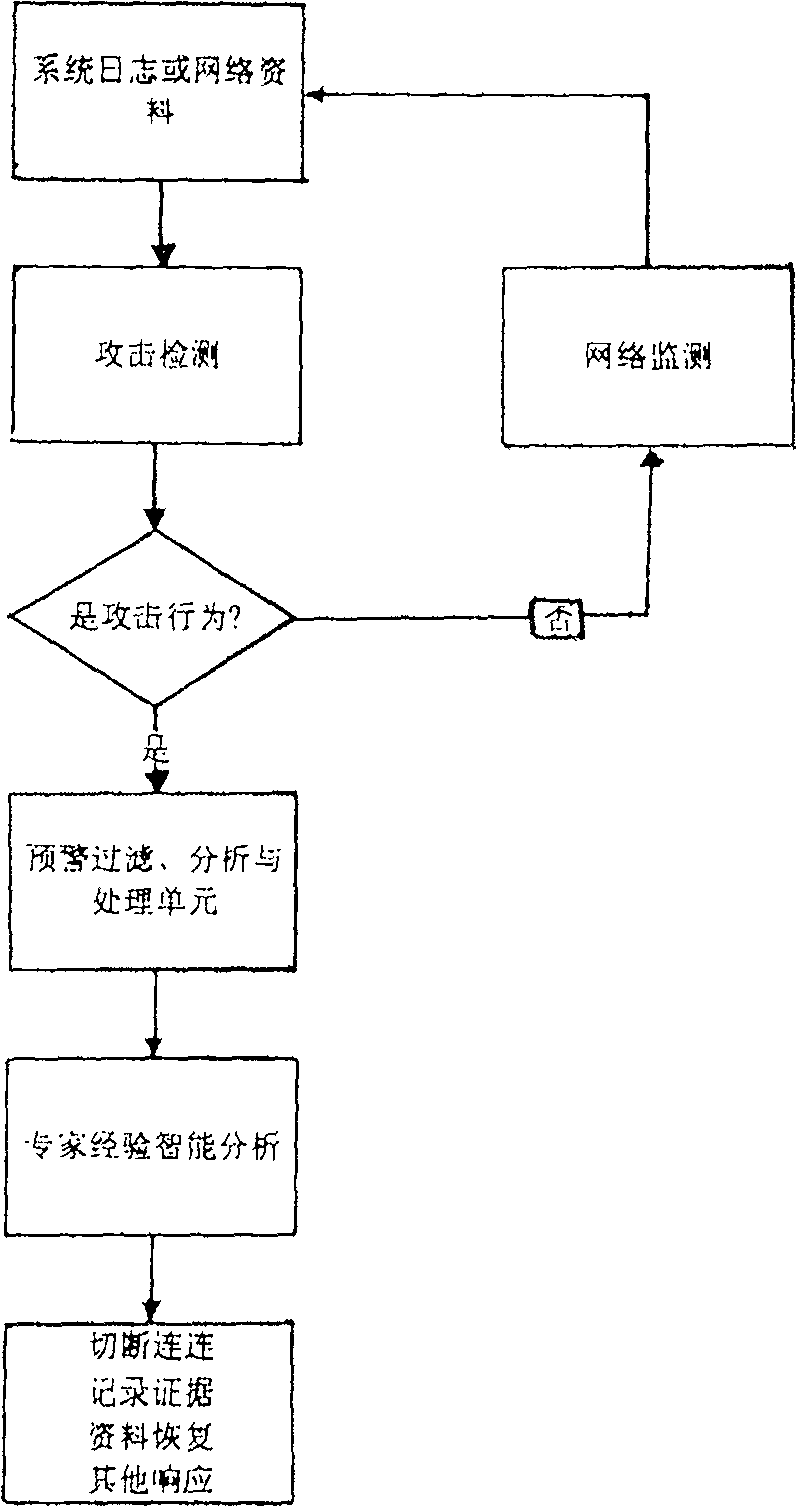

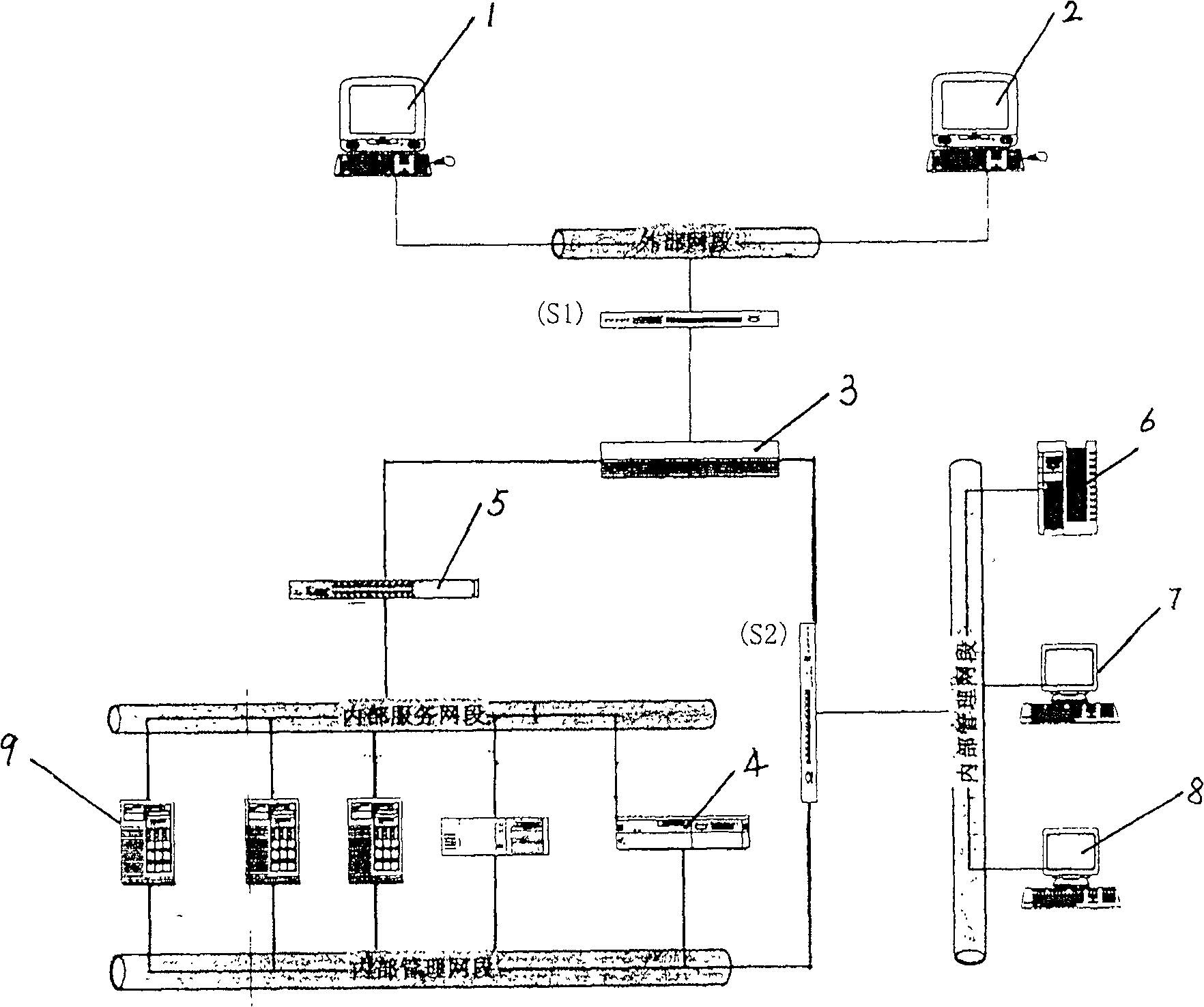

Computer network emergency response early-warning treatment system

InactiveCN1655516ARealize intelligent responseImprove survivabilityData switching networksProcess systemsProcess module

This invention relates to computer network emergency responding early warning process system, which is characterized by the following: the system comprises network composed of outer, servo and management network sections and filter and process modules. The normal visitor computer and attacker computer are connected to the router through outer network section, wherein one end of the router is connected to the service network section with eagle network tester and the other end is connected to the management section. The invention establishes the system aimed on the illegal attacking, which is cooperated with safety policy generation system.

Owner:上海三零卫士信息安全有限公司

Charge pump

ActiveCN102347687BSolve the crash problemApparatus without intermediate ac conversionConnection typeCapacitance

The invention relates to a charge pump. The charge pump can amplify an input voltage which is received at an input end and output the amplified output voltage at an output end. The charge pump comprises a plurality of transistors of which sources and drains are coupled, a plurality of overlapped transistors and a plurality of diode connection type transistors, wherein the transistors of which the sources and the drains are coupled serve as charging capacitors; the overlapped transistors are connected between the input end and the output end in a symmetric arrangement mode; and the diode connection type transistors are used for preventing the transistors of which the sources and the drains are coupled from being broken down in a charge transfer process and improving a charge transfer speed. The charge pump can be integrated on a chip by replacing the charging capacitors with the transistors of which the sources and the drains are coupled; and the problem of breakdown of the transistors can be solved by arranging the diode connection type transistors in the charge pump.

Owner:ACER INC

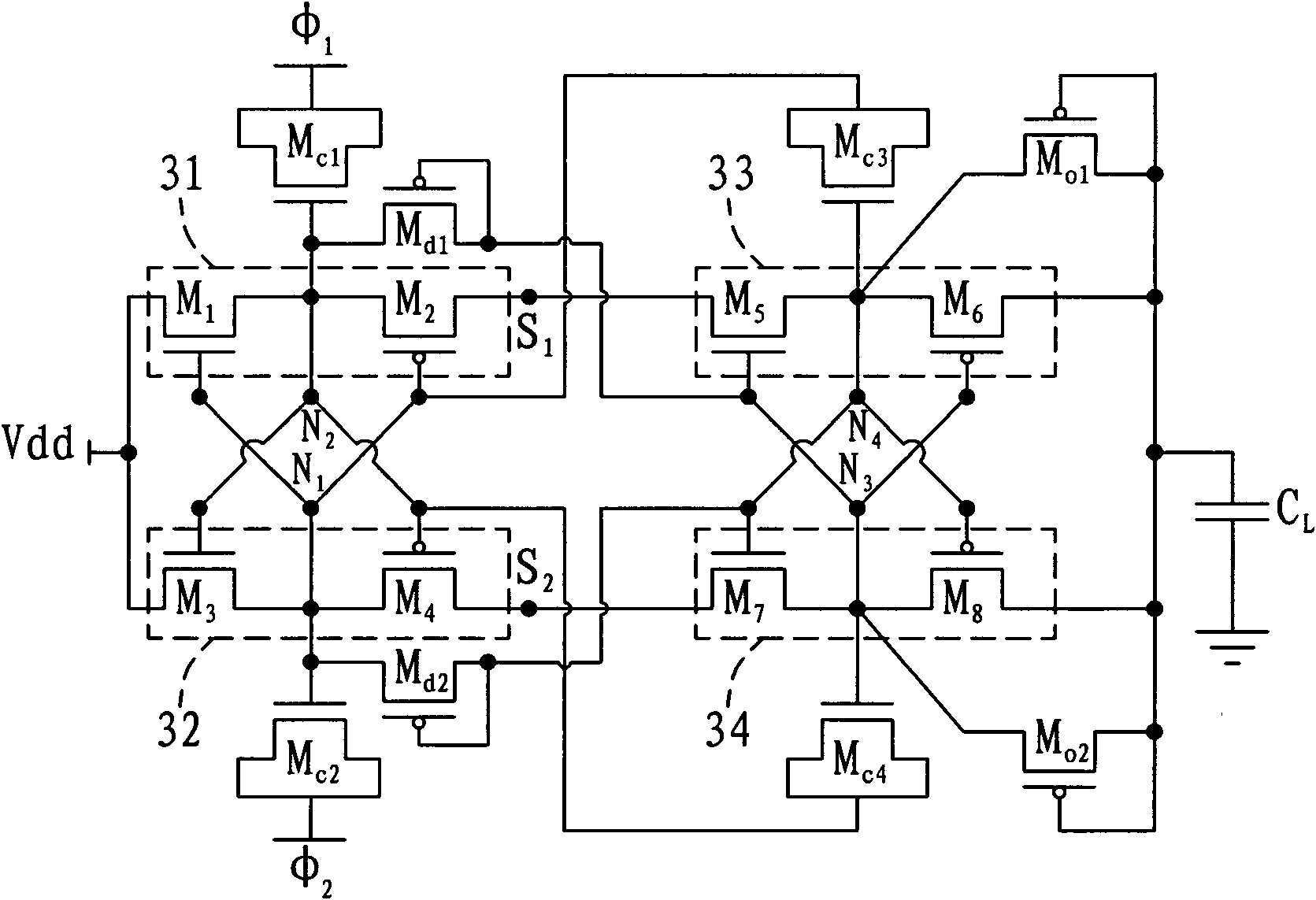

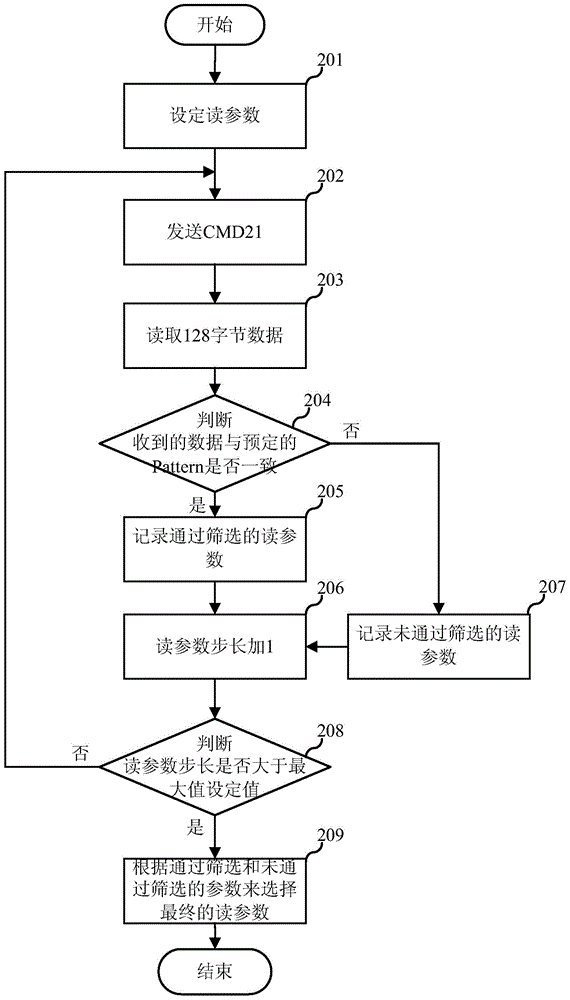

Read parameter selection method and apparatus

ActiveCN106484557ACorrect and effective selectionSolve the crash problemRedundant data error correctionApplication processorSelection method

The invention relates to the technical field of electronic devices and discloses a read parameter selection method and apparatus. The read parameter selection method comprises the following steps of reducing an output driving capability of a memory and an application processor; performing a data read operation on the memory, selecting out a wrong read parameter, and if the wrong read parameter cannot be selected out, continuing to reduce the output driving capability of the memory and the application processor until the wrong read parameter is selected out, wherein a clock signal corresponding to the wrong read parameter is a first clock signal; and selecting a read parameter of a sampling point corresponding to a second clock signal in a sampling period of the first clock signal, wherein the second clock is spaced from the first clock signal for a preset duration. Therefore, the read parameter of the memory can be correctly and effectively selected out and the problem of system halt caused by unreasonable read parameter selection is solved.

Owner:LEADCORE TECH +1

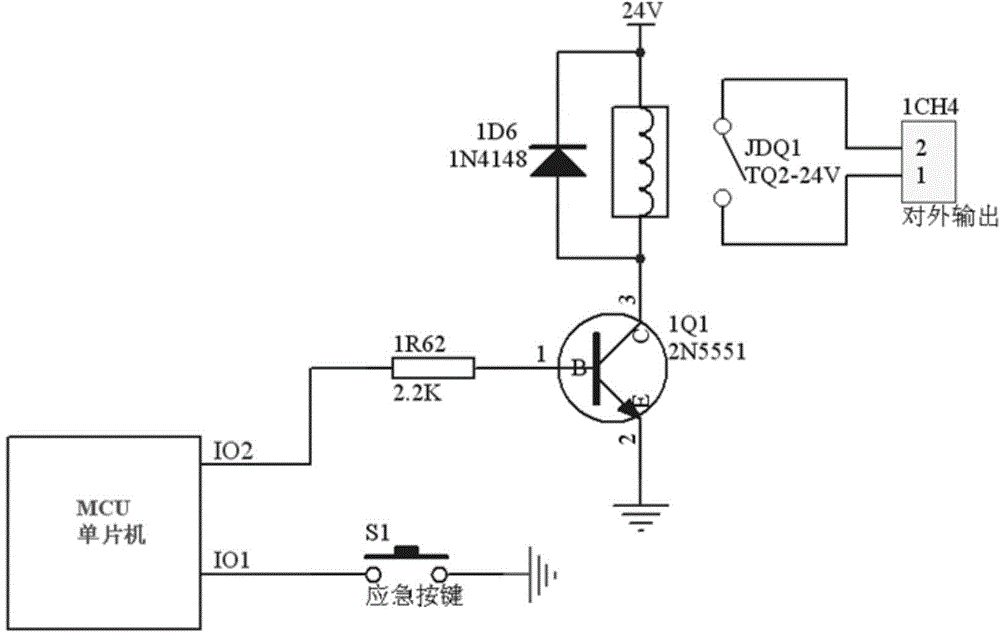

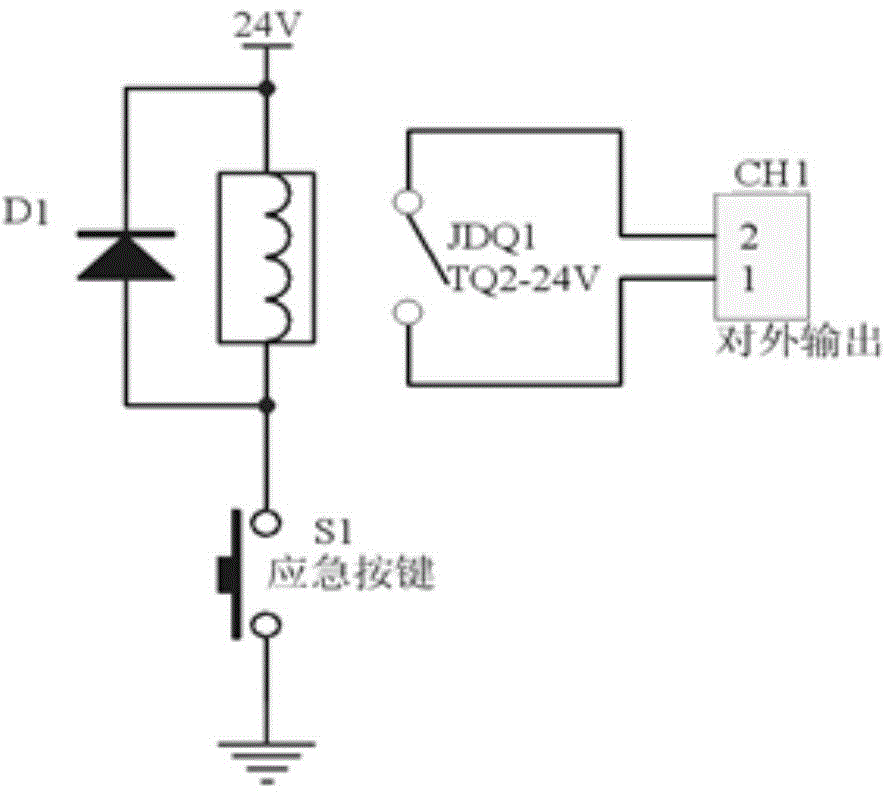

Emergency broadcasting circuit for broadcasting console

InactiveCN105471532ASolve the crash problemSimple designBroadcast specific applicationsMicrocomputerMicrocontroller

The invention provides an emergency broadcasting circuit for a broadcasting console, which comprises an emergency switch S1, a relay JDQ1 and an external output socket CH1, wherein the emergency switch S1 is connected with a coil of the relay JDQ1; two ends of the coil of the relay JDQ1 are parallelly connected with diodes D1; and the switching contact of the relay JDQ1 is connected with a first pin and a second pin of the external output socket CH1. The JDQ1 is obligatorily controlled directly via the emergency switch S1, the problem of single chip microcomputer crash caused by static electricity, fast electricity and other interference can be solved, the circuit design is simplified, reliability of the device is improved, and safe insurance is provided for outgoing of a passenger.

Owner:TIANJIN BEIHAI COMM TECH

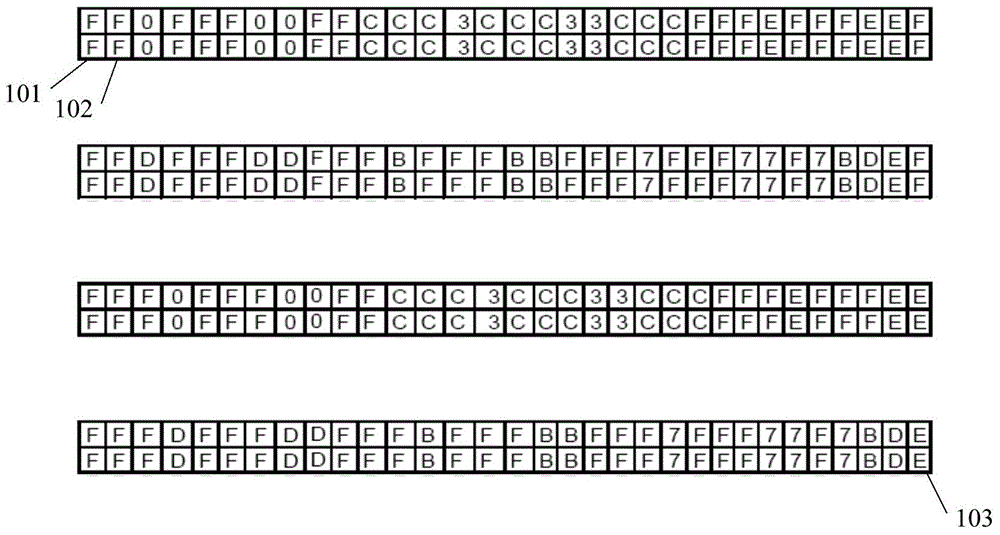

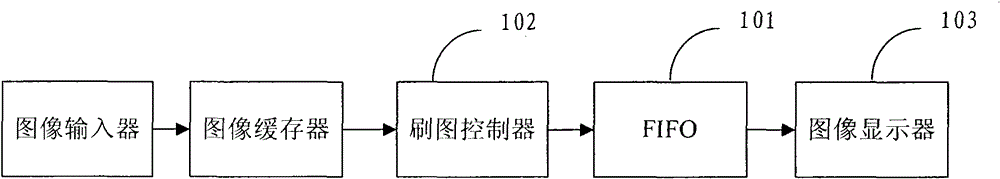

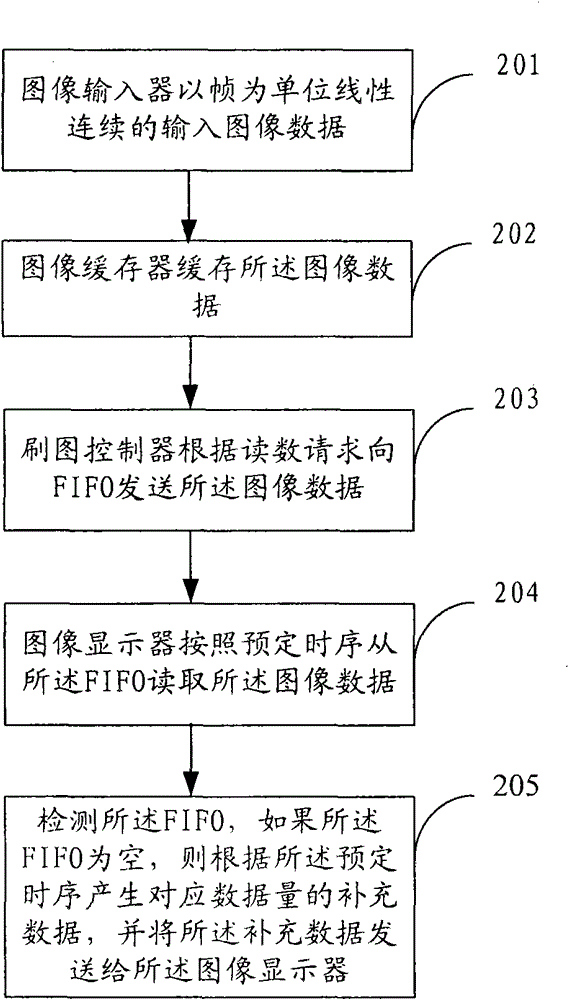

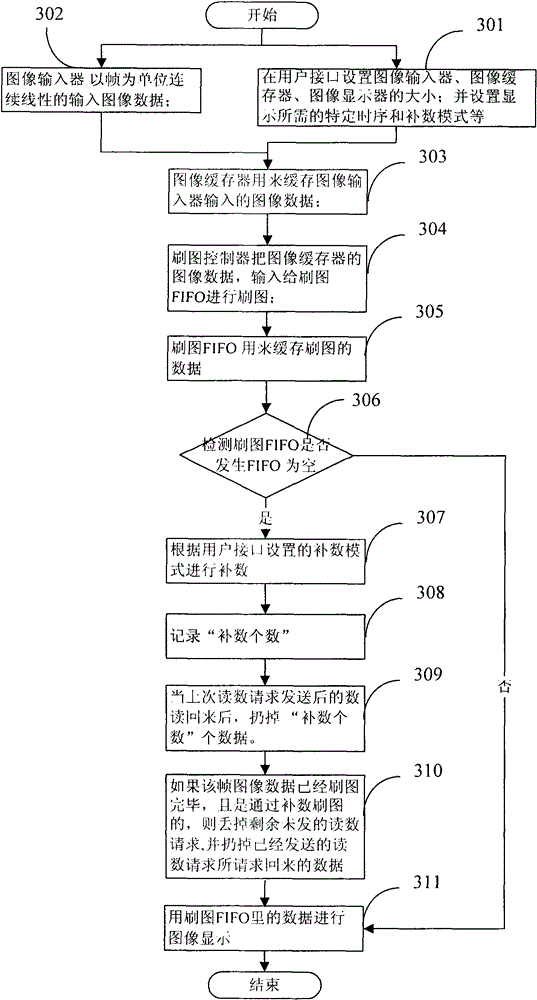

A method and system for brushing pictures

ActiveCN101930348BSatisfy the drawing needsSolve the crash problemDigital output to display deviceDisplay deviceSupplementary data

The invention provides an image brushing method and an image brushing system. The image brushing method includes: an image input device linearly and continuously inputs image data in frame units; an image buffer caches the image data; and the image brushing controller sends a request to the FIFO according to the reading request. Send the image data; the image display reads the image data from the FIFO according to a predetermined timing; further including: detecting the FIFO, and if the FIFO is empty, generating supplementary data corresponding to the data amount according to the predetermined timing. , and sends the supplementary data to the image display. The invention can solve the problem of screen crashes caused by insufficient bandwidth in a fixed-timing image brushing system.

Owner:WUXI ZGMICRO ELECTRONICS CO LTD

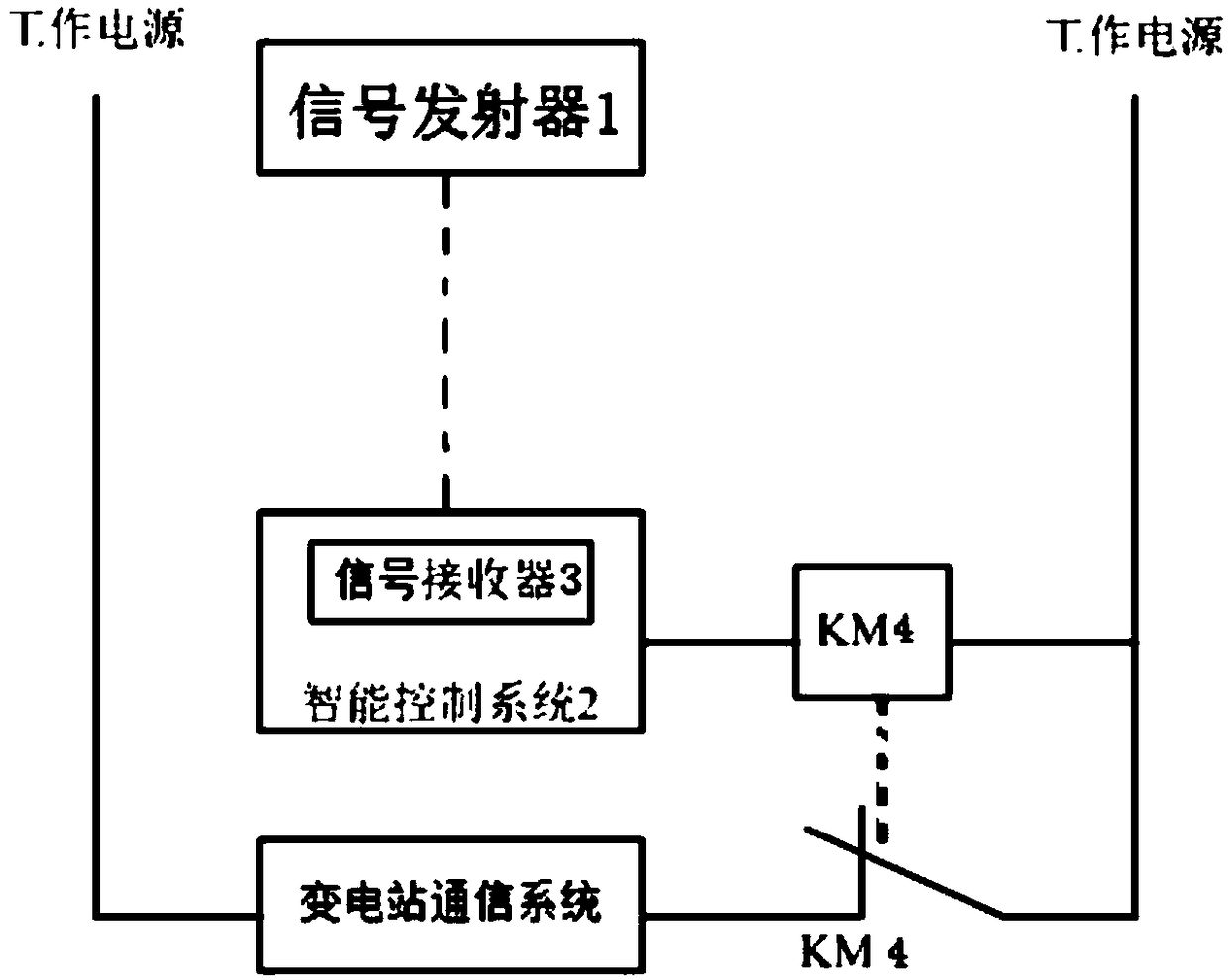

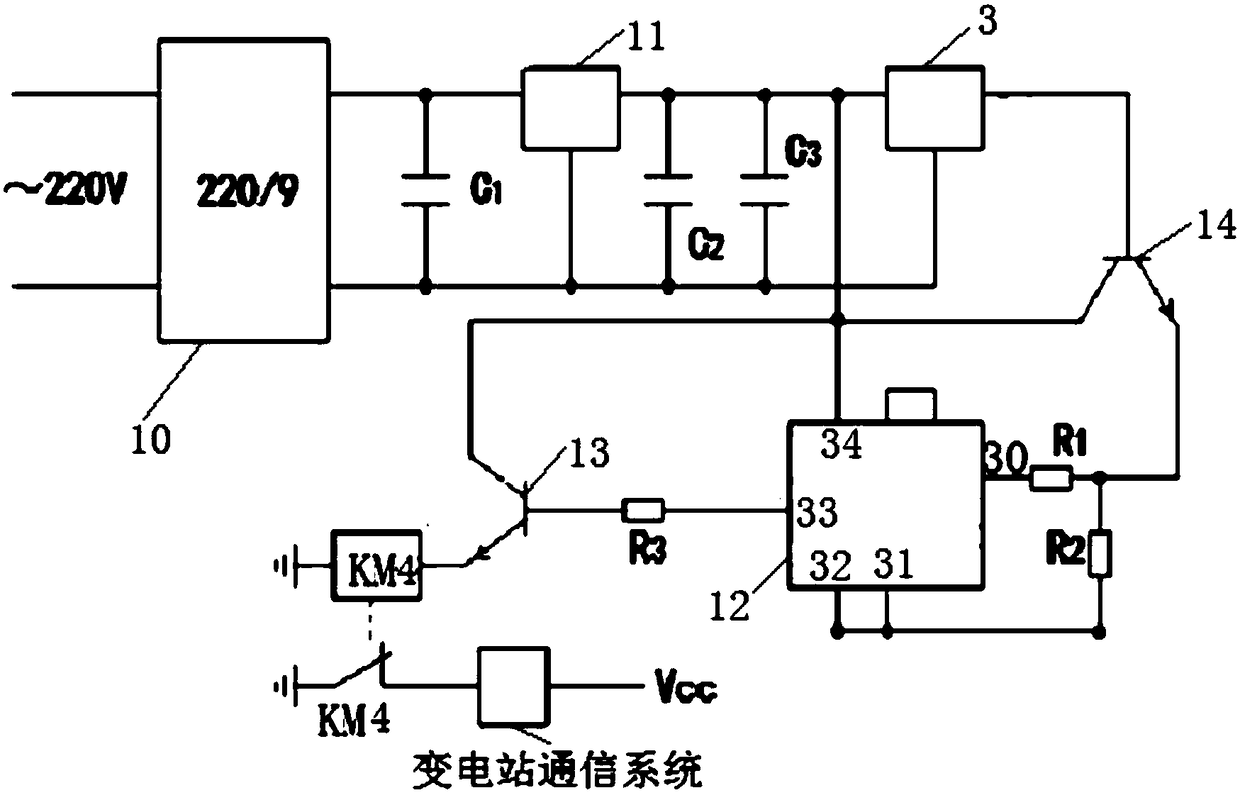

Remote restart device of substation communication system

ActiveCN105958655BGuaranteed uptimeRun economyCircuit arrangementsInformation technology support systemCommunications systemTransformer

Disclosed is a remote restart apparatus for a communication system of a transformer substation. The remote restart apparatus is characterized by comprising a signal emitter, an intelligent control system and a relay KM, wherein a signal receiver is embedded in the intelligent control system; and the intelligent control system controls the state of the normally-closed contact of the relay KM so as to realize the power off-power transmission process of the communication system of the transformer substation. The remote restart apparatus for the communication system of the transformer substation is creative in conception, simple in structure, high in practicability, and capable of effectively solving the problem of dead halt of the communication system of the 35kV unattended transformer substation, greatly shortening the dead-halt failure clearance period of the communication system, and improving the safety and reliability of the operation of the equipment; and meanwhile, the one-to-many operating mode brings convenience to the operation and maintenance staff.

Owner:AKSU POWER SUPPLY COMPANY STATE GRID XINJIANG ELECTRIC POWER

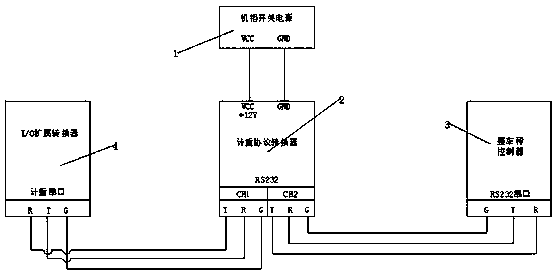

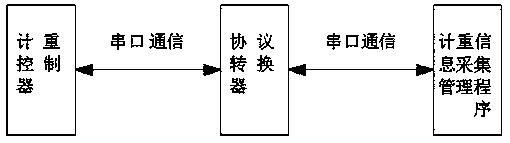

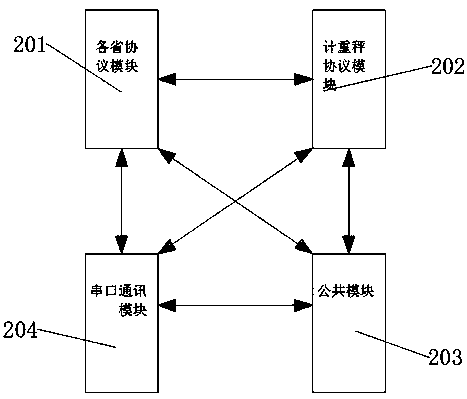

Embedded weighing scale protocol converter

InactiveCN110375836ASolve the crash problemFix stability issuesProgramme controlComputer controlCommunication interfacePower switching

The invention discloses an embedded weighing scale protocol converter, which comprises a machine cabinet power switch, a weighing protocol converter, a whole-vehicle scale controller and a weighing serial port, wherein the machine cabinet power switch is electrically connected with the weighing protocol converter, the weighing protocol converter is interactively connected with the whole-vehicle scale controller by means of an RS232 serial port, and the weighing protocol converter is interactively connected with the weighing serial port by means of a MyControl MC-B803. The embedded weighing scale protocol converter improves the original method of using a dynamic library for a weighing scale communication protocol and charging software into a method adopting a software-hardware combined protocol converter, effectively solves the problems of crash or instability in the dynamic library loading, calling and the like process, and integrates communication protocols of mainstream weighing scale manufacturers into the protocol converter; and one end of the embedded weighing scale protocol converter is adapted to the weighing scale communication protocol, and the other end is adapted to charging software communication interfaces in different provinces, so that the charging system can acquire data of the weighing scale stably and efficiently.

Owner:甘肃紫光智能交通与控制技术有限公司

Method and device for starting a set-top box

InactiveCN102883220BSolve the crash problemFull boot programSelective content distributionBootingSet top box

The invention is applicable to the technical field of a STB (Set Top Box) and provides a STB starting method and a STB starting device. The method comprises the following steps of: when the STB is started, a bootstrapper and block state information in an NAND Flash bootstrapper preserved storage region are read; the STB operates a bootstrapper initialization memory; when data in a NAND Flash is loaded into the STB, the STB loads a binary file of an initiator in a normal block into the memory until completing loading the complete initiator; and the STB operates the initiator in the memory to be started. According to the invention, the initiator is written into the normal block by acquiring the block state information in the process of burning the NAND Flash and storing the block state information into the NAND Flash; and when the STB is started, the block state information is read, the initiator in the normal block is loaded into the memory and the initiator is executed to start the STB, so that the problem of crash in the starting process, which is caused by the case that data of a bad block is possibly loaded when the bootstrapper loads initiators of more than one block, is solved.

Owner:SHENZHEN JIUZHOU ELECTRIC

Computer network emergency response early-warning treatment system

InactiveCN100536400CRealize intelligent responseImprove survivabilityData switching networksNetworked systemNetwork management

The invention relates to an early warning processing system for computer network emergency response, characterized in that: the system includes a network consisting of three network segments of external, service and management, and two modules of filtering and processing; Both computers are connected to the router through the external network segment, one end of the router is connected to the service network segment equipped with the Hawkeye network intrusion detector, and the other end of the router is connected to the management network segment. The present invention overcomes the limitations of traditional intrusion detectors in response to intrusion behavior, and establishes an early warning processing system for illegal intrusion of computer networks. The early warning processing system cooperates with the security policy generation system to realize the computer network system Intelligent response and rapid recovery, realizing a computer network emergency troubleshooting system that combines active defense and emergency response disaster recovery capabilities. It integrates attack and evidence collection technology, networked system disaster recovery technology, and system and data rapid recovery technology. Based on the advanced emergency response technology, a relatively intelligent control and processing platform is established.

Owner:上海三零卫士信息安全有限公司

A dual-core working system and method for an electronic label system

ActiveCN103530271BMeet anti-interferenceLow costMultiple digital computer combinationsTransceiverInterference resistance

Owner:汉朗网络信息科技(北京)有限公司

Method and apparatus for correcting data error in image processing system

InactiveCN101511029BCrash will notSolve the crash problemClosed circuit television systemsDigital video signal modificationImaging processingData error

The invention provides a data error correction method for image processing systems and a device thereof, and the method comprises a row judgment step and a column judgment step. The row judgment step: whether the receiving data size of the current row is larger than the threshold of the row width is judged, if so, redundant data is dropped, otherwise the data of the next row is adopted to make upthe current row; the column judgment step: whether the receiving data size of the current frame is larger than the threshold of the frame height is judged, if so, redundant data is dropped, otherwisethe data of the next column is adopted to make up the current frame. The method has an advantage that dead halt or other abnormal conditions of the system caused by row data deficiency or frame data deficiency can be prevented.

Owner:WUXI ZGMICRO ELECTRONICS CO LTD

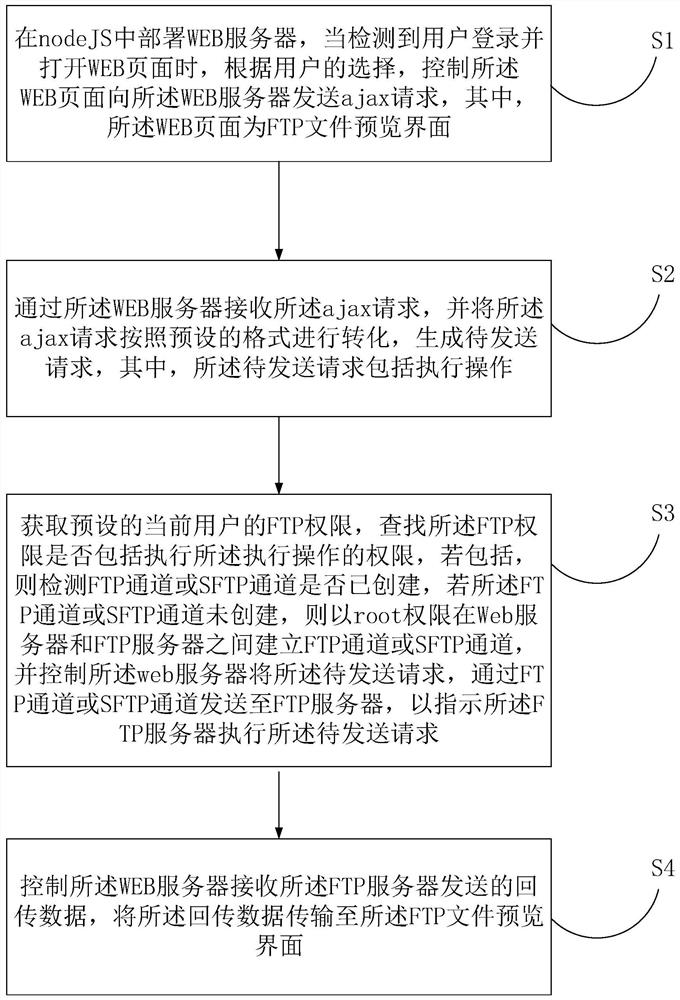

Method for data transmission between web page and ftp server and related equipment

ActiveCN111835852BIncrease profitEasy to operateTransmissionCreation/generation of source codeData transportEngineering

The embodiments of this application belong to the technical field of management and are applied to the field of smart government affairs, and relate to a method for data transmission between a WEB page and an FTP server and related equipment, including: deploying a WEB server in nodeJS, and controlling the WEB page according to the user's selection Send an ajax request to the WEB server; receive and convert the ajax request through the WEB server, and generate a pending request containing the execution operation; obtain and find out whether the user's FTP permission includes the execution operation; if so, detect whether the FTP or SFTP channel has been created; If it is not created, establish an FTP or SFTP channel between the WEB server and the FTP server with root authority, control the WEB server to send the request to be sent to the FTP server; control the WEB server to receive the return data sent by the FTP server, and transmit the return data Go to the FTP file preview interface. The user's FTP permission information can be stored in the blockchain node. The present application avoids the situation that the FTP server is down due to the excessive number of channels connected to the FTP server.

Owner:深圳赛安特技术服务有限公司

A dual-battery control device and method for a mobile terminal

ActiveCN106532902BSolve the crash problemTroubleshoot the systemEnd cell switching arrangementsEmergency power supply arrangementsElectricityElectrical battery

The present invention discloses a mobile terminal dual-battery control device and method. The dual-battery control device is connected with a main battery and a secondary cell and comprises a main battery detection module, a secondary battery detection module, an enabled module and a control switching module. The main battery detection module detects the size of the main battery voltage and output the first detection signals corresponding to the level. The secondary cell detection module detects the size of the secondary cell voltage and outputs the second detection signals corresponding to the level. The enabled module outputs outage signals according to the input instruction. The main battery supplies power when the control switching module determines that the main battery has electricity supply according to the high-low level of the first detection signals and the second detection signals, the secondary cell supplies power when the control switching module determines that the main battery has no electricity supply and the secondary cell has the electricity supply, so that the man battery power supply is automatically switched to the secondary cell power supply when the main battery has no electricity supply, and the main battery can be replaced in the turn-on state. When the secondary cell supplies power, the mobile terminal can be restarted according to the outage signals to solve the problems of crashing of the mobile terminal or system faults.

Owner:厦门九品芝麻信息科技有限公司

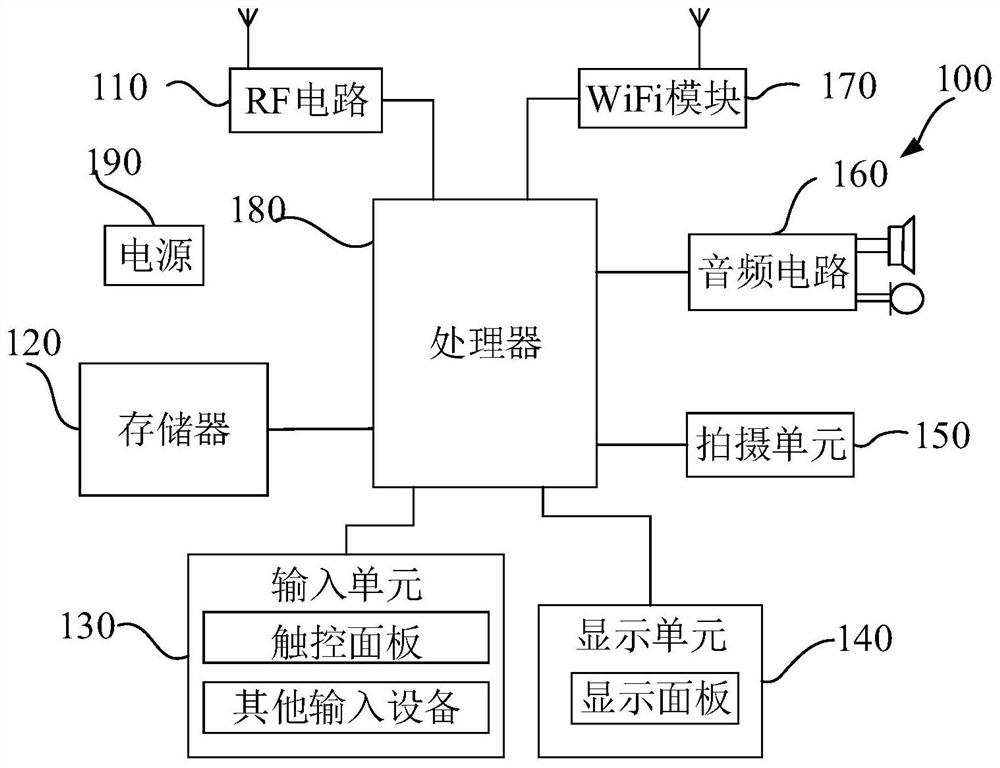

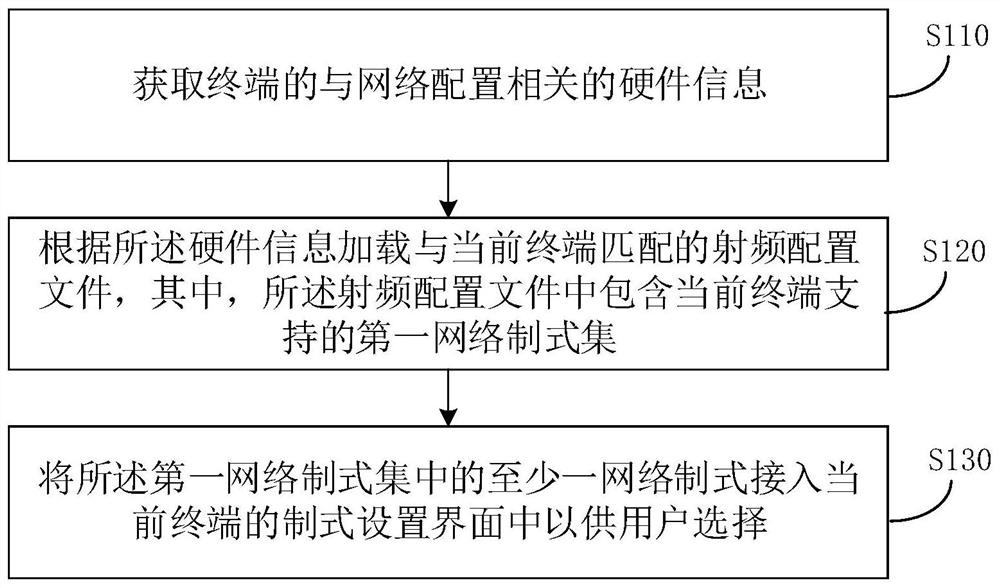

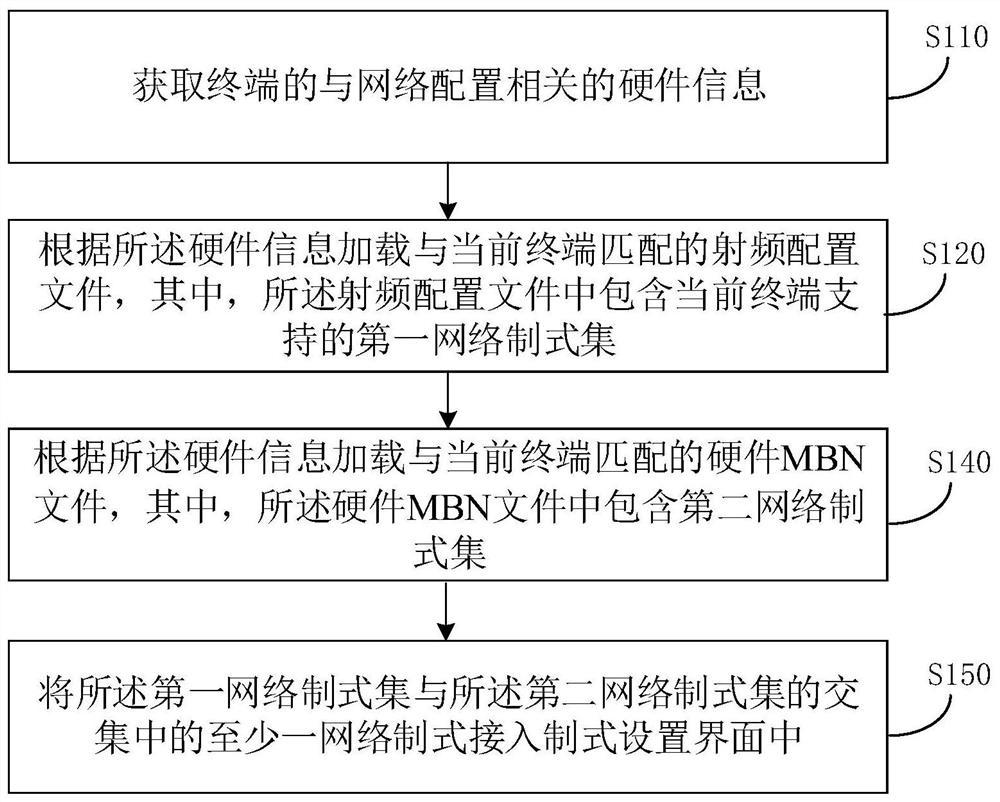

Network configuration method and device, terminal and readable storage medium

PendingCN113840308AImprove experienceSolve the crash problemAssess restrictionComputer hardwareRadio frequency

The embodiment of the invention provides a network configuration method and device, a terminal and a readable storage medium. The method comprises the steps that hardware information, related to network configuration, of the terminal is acquired; a radio frequency configuration file matched with the terminal is loaded according to the hardware information, and the radio frequency configuration file comprises a first network system set supported by the terminal; and at least one network type in the first network type set is accessed into a type setting interface of the terminal to serve as an optional network type for a user to select. According to the technical scheme of the invention, the network type selected by the user can be prevented from being not the network type supported by the bottom hardware of the terminal, so that the crash problem is effectively solved, and the user experience is improved.

Owner:ONEPLUS TECH SHENZHEN

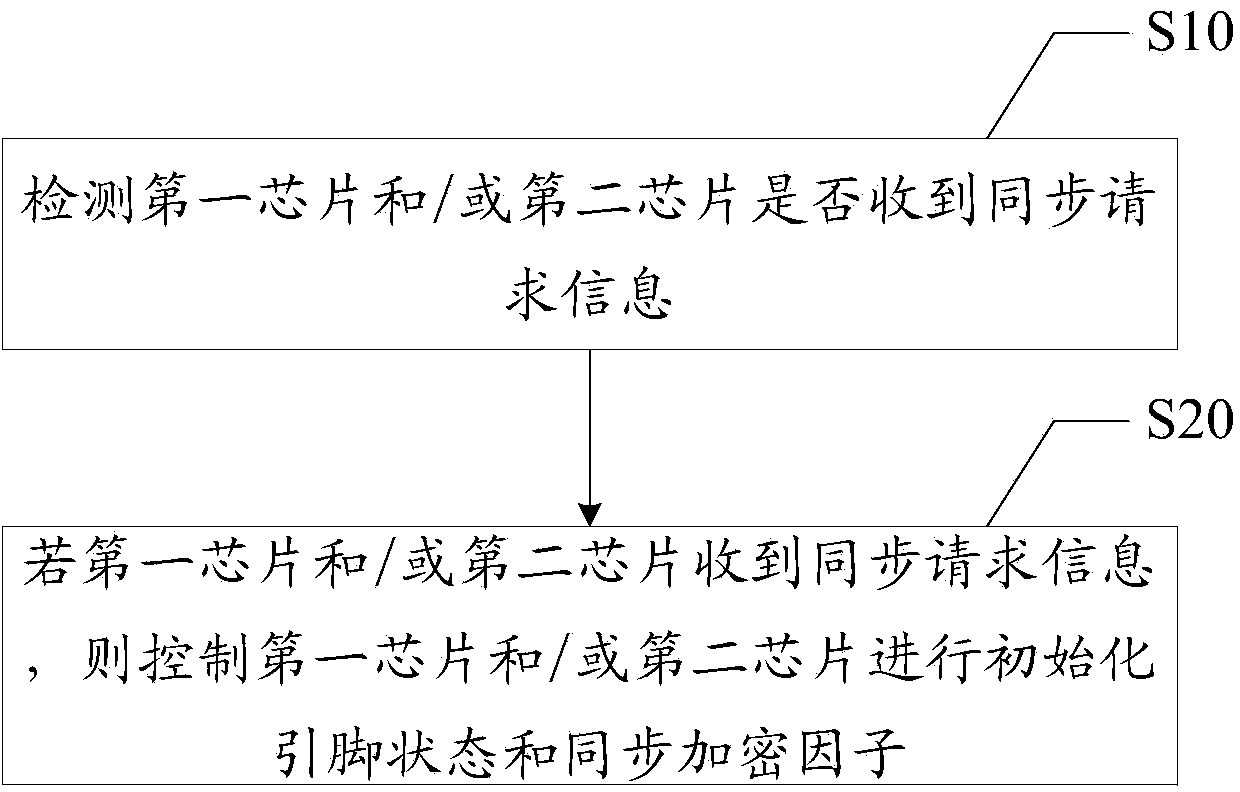

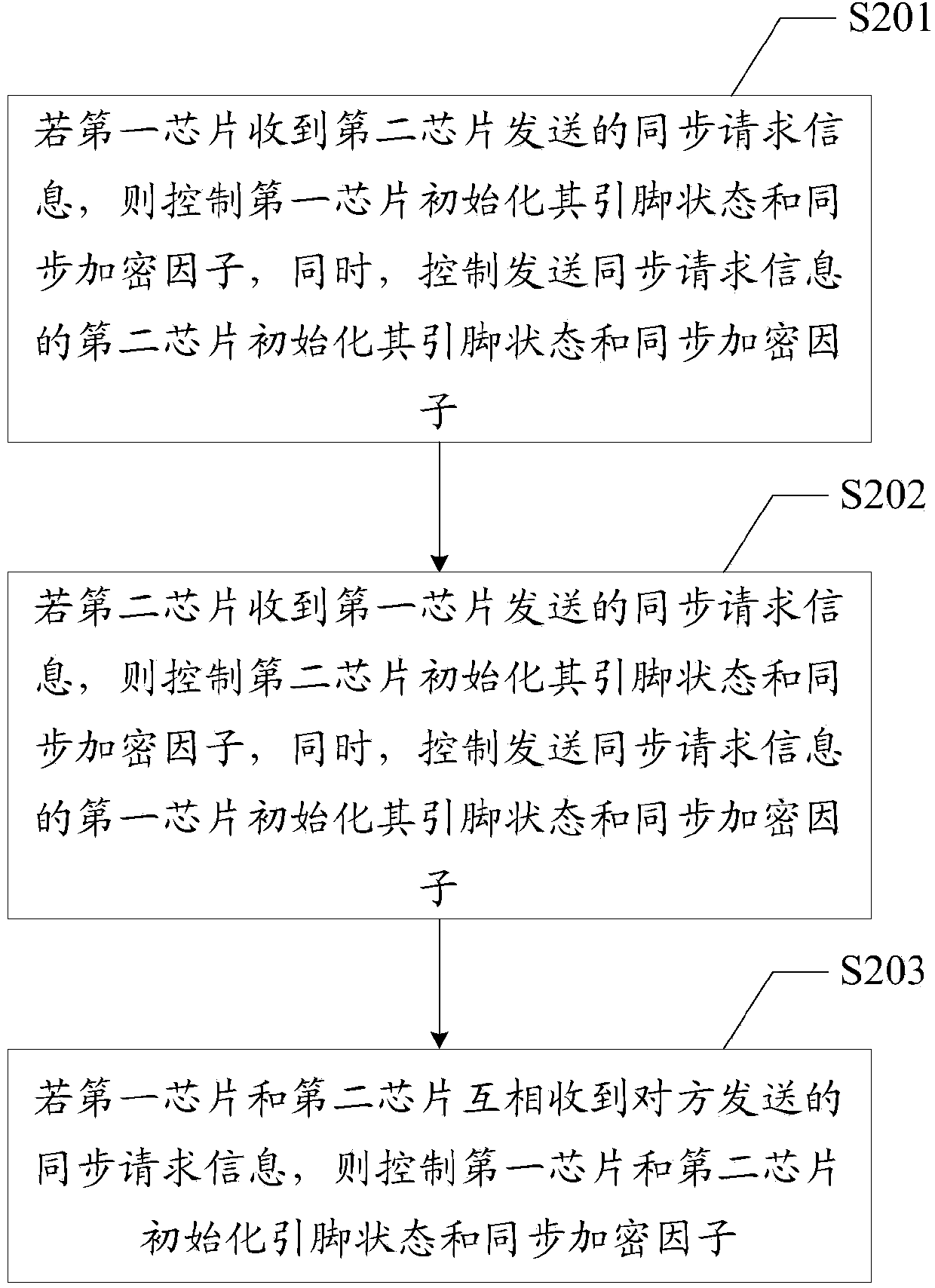

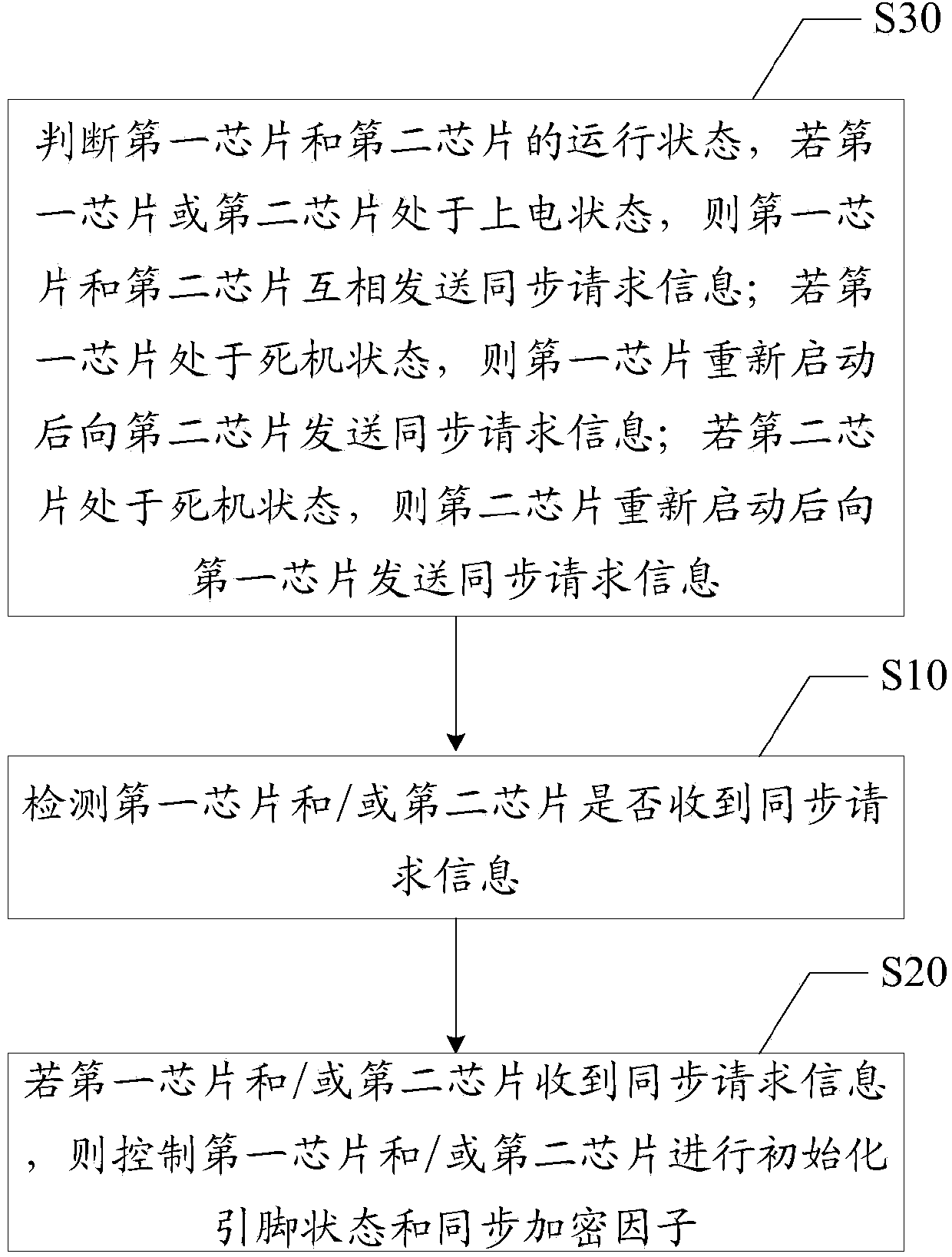

Method for preventing dead halt and laser bar code scanning platform

ActiveCN104200186ASolve the crash problemPrevent crashError detection/correctionSensing by electromagnetic radiationComputer hardwareTime cost

The application discloses a method for preventing dead halt. The method for preventing the dead halt includes steps: detecting whether synchronization requesting information which is used to inform a receiver of the synchronization requesting information to initialize lead foot status and synchronize encryption factors so as to synchronize the receiver of the synchronization requesting information with a sender of the synchronization requesting information is received by a first chip and / or a second chip; if the synchronization requesting information is received by the first chip and / or the second chip, controlling initialization of the first chip and the second chip. The invention further discloses a laser bar code scanning platform. The method for preventing the dead halt and the laser bar code scanning platform use a small number of chip resources, intelligently solve the problem that the laser bar code scanning platform halts on the premise of not needing to restart the laser bar code scanning platform, and thereby save time of restarting the laser bar code scanning platform when the laser bar code scanning platform halts, reduce time cost of users, and simultaneously improve continuity and experience feeling degrees of using the laser bar code scanning platform for users.

Owner:SHENZHEN XINGTONG WULIAN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com