Machining method of high-strength handheld mower blade

A processing method and a hand-held technology, applied in the direction of harvesters, cutters, manufacturing tools, etc., can solve the problems of unstable heat treatment deformation quality, easy reduction of knife edge hardness, unstable dynamic balance, etc., to solve heat treatment deformation problems and improve Uniformity, the effect of improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

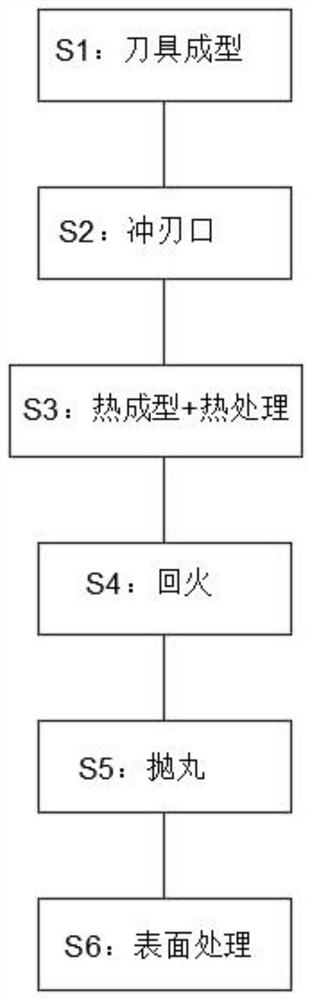

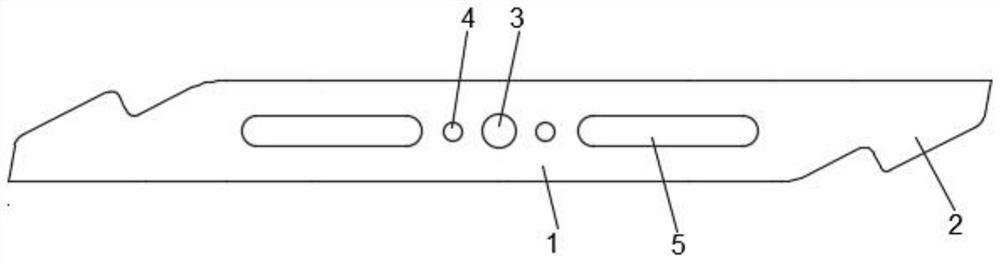

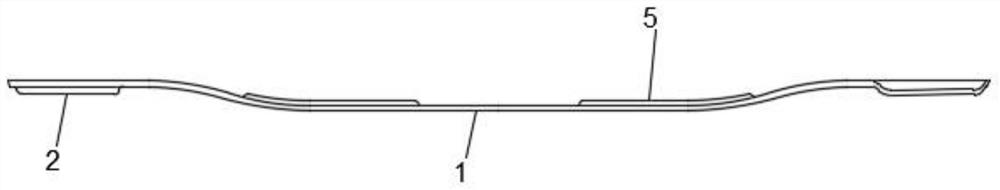

[0030] Such as Figure 1-3 Shown; A kind of high-strength hand-held lawn mower blade processing method, described high-strength hand-held lawn mower blade comprises blade body 1, cutting edge 2, mounting hole 3, positioning hole 4 and cooling groove 5, comprises the following steps:

[0031] S1: tool forming; inject molten steel into the mold, and cool the blade after forming, use a milling machine to roughly machine the mounting hole 3, the positioning hole 4 and the cooling groove 5;

[0032] S2: Punch the cutting edge, perform multiple continuous stamping on the cutting edge 2 position;

[0033] S3: Thermoforming + heat treatment, the tool is put into a 1000-degree heating furnace for hot forging and pressing, and isothermally quenched for 10 minutes. The hardness of the blade after quenching is 40-45HRC; thermoforming + heat treatment are combined into one process to replace the traditional one. The heat treatment and tempering shaping process of the process can not only ...

Embodiment 2

[0039] In the step S1, the molten steel is prepared from the following raw materials in parts by weight: 70 parts of carbon, 110 parts of chromium, 18 parts of manganese, 40 parts of silicon, 15 parts of tungsten, 18 parts of vanadium, 6 parts of titanium nitride, 2 parts of aluminum, 1 part nickel, 1 part rare earth, 9100 parts iron.

[0040] The rare earth is made by mixing and stirring lanthanum, neodymium and samarium, wherein 10 parts of lanthanum, 5 parts of neodymium, and 98 parts of samarium are added. Rare earth elements are added to improve the uniformity of carbide distribution in the cutter, thereby improving the overall performance of the cutter.

[0041] The distance between the upper side and the lower side of the cutting edge 2 is 7 mm, and the distance between the lower side of the blade body 1 and the upper side of the cutting edge 2 is 15.5 mm.

[0042] The overall dynamic balance of the blade of the high-strength hand-held lawn mower at a distance of 150 mm...

Embodiment 3

[0046] In the step S1, the molten steel is prepared from the following raw materials in parts by weight: 80 parts of carbon, 130 parts of chromium, 12 parts of manganese, 35 parts of silicon, 20 parts of tungsten, 10 parts of vanadium, 8 parts of titanium nitride, 4 parts of aluminum, 2 parts nickel, 2 parts rare earth, 9000 parts iron.

[0047] The rare earth is prepared by mixing and stirring lanthanum, neodymium and samarium, including 10 parts of lanthanum, 5 parts of neodymium and 98 parts of samarium.

[0048] The distance between the upper side and the lower side of the cutting edge 2 is 7 mm, and the distance between the lower side of the blade body 1 and the upper side of the cutting edge 2 is 15.5 mm.

[0049] The overall dynamic balance of the blade of the high-strength hand-held lawn mower at a distance of 150 mm from the center of rotation is less than 800 mg.

[0050] In the step S5, the model of the horizontal machining center is M125.

[0051] In the step S5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com