Process for drying by imitating sunlight with drying structure of laundry machine and removing ozone by catalyzed sorption

A washing machine, a technology of imitating sunlight, which is applied in the field of using a washing machine drying structure to imitate sunlight to dry and catalyze adsorption to remove ozone, can solve the problems of not providing the use of superoxide negative ions to decompose ozone, and not being disclosed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment is mainly about the analysis and synthesis of simulated sunlight.

[0031] The near-infrared used in the present invention refers to light with a wavelength of 600-1200 nm, and the preferred light is near 760 nm, or between 980-990 nm. The radiation time is 2 to 3 minutes,

[0032] The far infrared used in the present invention refers to a wavelength of 2.5 to 50 microns, preferably a wavelength of 3 to 25 μm, more preferably 5 to 20 μm, and a most preferred wavelength of 8 to 15 μm. Stay for 3 to 4 minutes to make the whole fiber of the clothes and mattress loose in the far-infrared radiation area. Long-wave infrared rays generally penetrate the skin at a depth of 0.05-1 mm, with a maximum penetration of 3-5 mm, while short-wave infrared rays have strong penetrating power, generally at 1 cm.

[0033] The ultraviolet light used in the present invention is selected from a light source with a wavelength range of 180-380nm, preferably with a wavelength of...

Embodiment 2

[0038] This embodiment mainly applies the principle in Embodiment 1 to the pulsator washing machine.

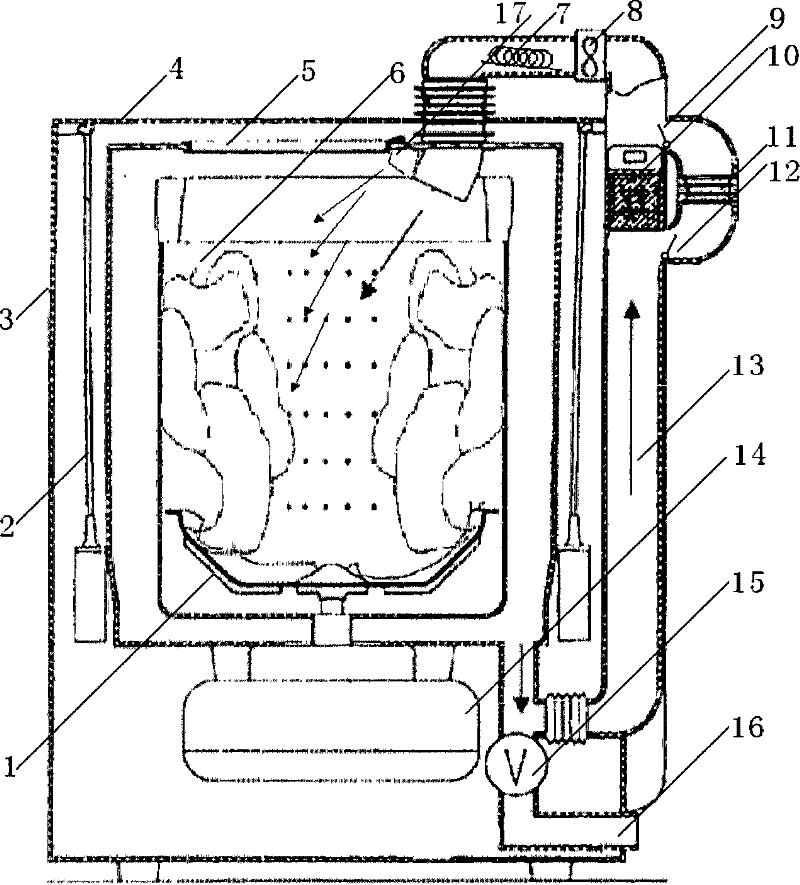

[0039] Applicable to the washing and drying machine described in the present invention, see the attached figure 1 , comprising a casing 3, a casing cover 4 is arranged above the casing 3, an outer barrel is hung in the casing 3 with a damping rod 2, an outer barrel cover 5 is arranged on the outer barrel, an inner barrel is arranged in the outer barrel, and the inner barrel A pulsator 1 is arranged at the bottom of the outer barrel, an air passage 13 is arranged outside the bottom to the top of the outer barrel, a lint filter 10, a heater 7, and a fan 8 are arranged on the upper part of the air passage 13, and a drive assembly is arranged at the bottom of the outer barrel 14 is used to drive the pulsator 1, and a solenoid valve 15 is set in the drain pipe 16 to control the discharge of water, and the laundry 6 is placed in the washing inner tub.

[0040] A bypass pipe is ar...

Embodiment 3

[0045] This embodiment is mainly to add sunshine factor detergent spraying device in the structure in embodiment two, and this device is arranged on the outer barrel top of washing machine, can be located at the below of near infrared, far infrared, ultraviolet generating device (not shown in the figure ). At the same time or before turning on the near-infrared, far-infrared, and ultraviolet generating devices, turn on the sunlight factor detergent spray device to accelerate the decomposition of clothing dirt and eliminate odors. The spray device is a small spray device, and a light nozzle with a lower spray density can also be used , the spraying time is the best for making the clothes roll all over for a week, that is, 1-2 minutes, so that the spraying is completely covered on the clothes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com