Automatic on-off system

An automatic clutch and clutch technology, applied in the field of automatic clutch system, to achieve the effect of preventing accidental flameout, simple structure and sensitive control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

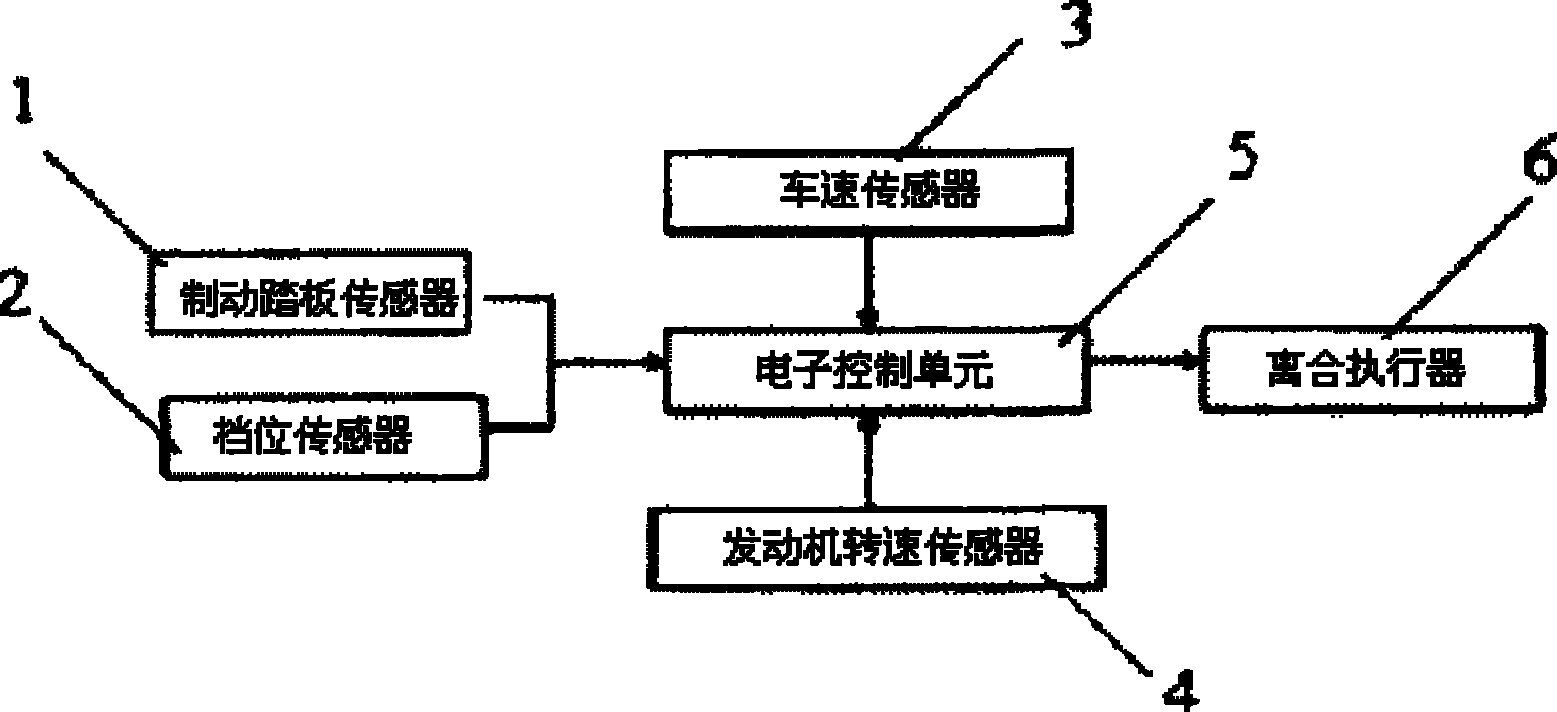

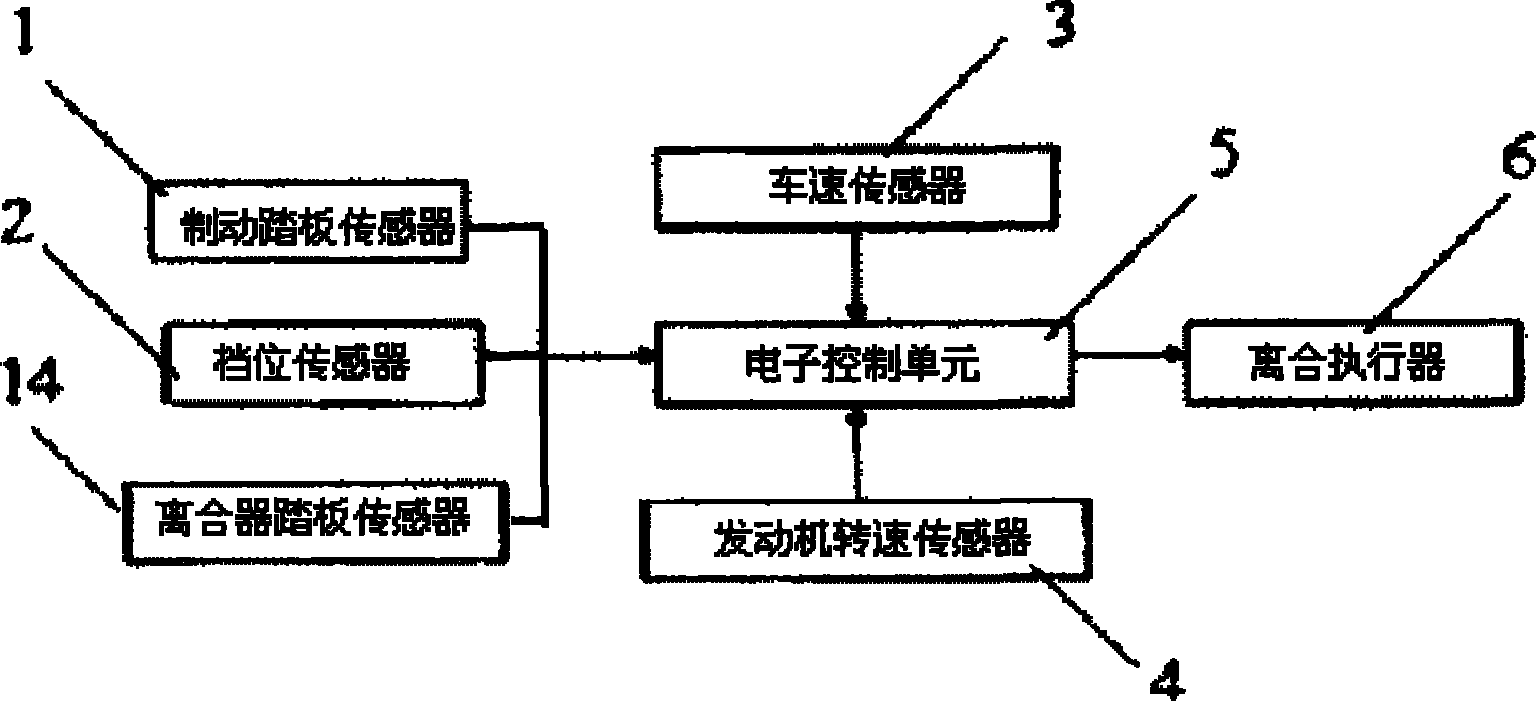

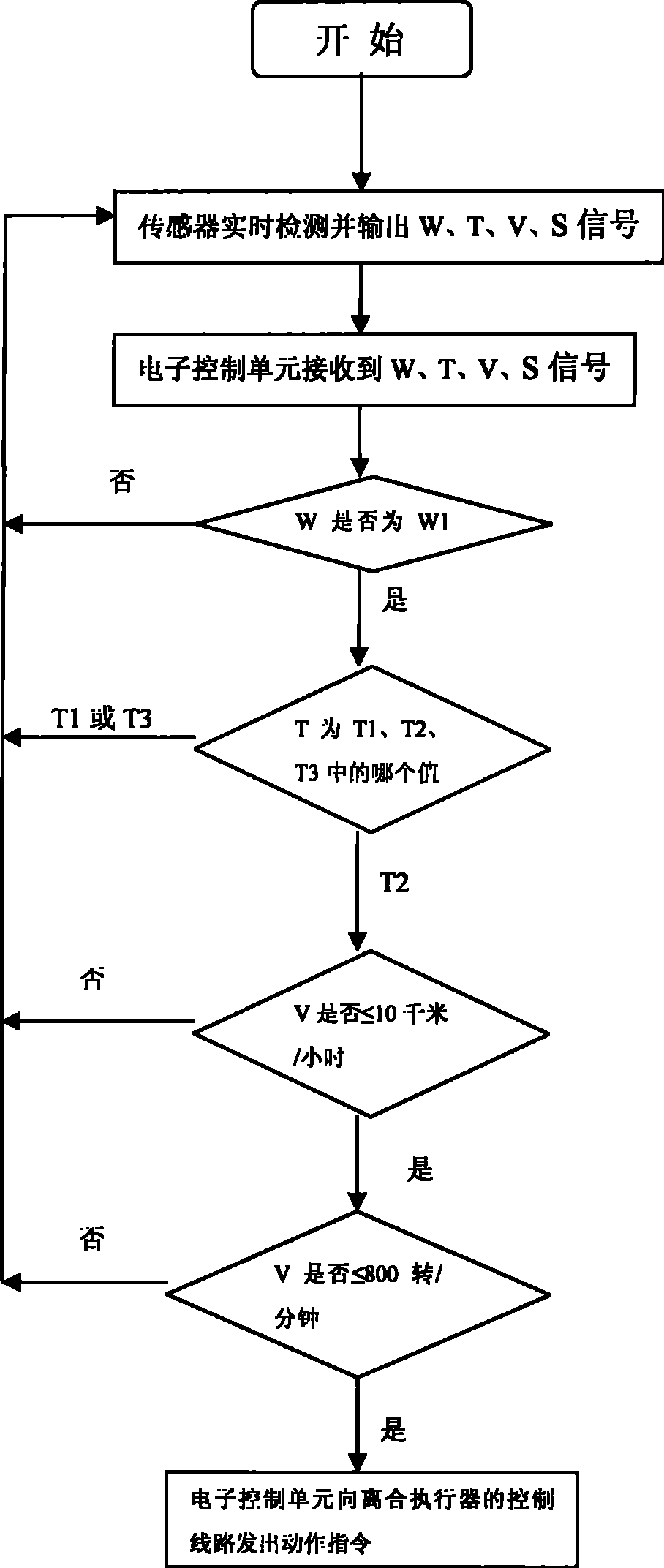

[0018] like image 3 As shown, the functions of each sensor and electronic control unit in automatic control are:

[0019] The brake pedal sensor 1 is used to convert the action of the brake pedal 7 into an electrical signal W, and input the electrical signal W into the electronic control unit;

[0020] The gear position sensor 2 is used to convert the gear position signal into an electrical signal T, and input the electrical signal T into the electronic control unit;

[0021] The vehicle speed sensor 3 is used to collect the vehicle speed and convert it into an electrical signal V, and input the electrical signal V to the electronic control unit;

[0022] The engine speed sensor 4 is used to collect the engine speed and convert it into an electrical signal S, and input the electrical signal S to the electronic control unit;

[0023] The electronic control unit 5 is used to send or not send instructions to the clutch actuator 6 according to the electric signal W, the electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com