Method for determining correction factor of belt balance real object simulating detection device

A detection device and correction coefficient technology, which is applied in measuring devices, weighing equipment for continuous material flow, and weighing equipment testing/calibration, etc., can solve the problem of high device cost, affecting the development of circular chain code technology, and the development prospect of circular chain code Restrictions and other issues, to overcome the effect of gravity error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

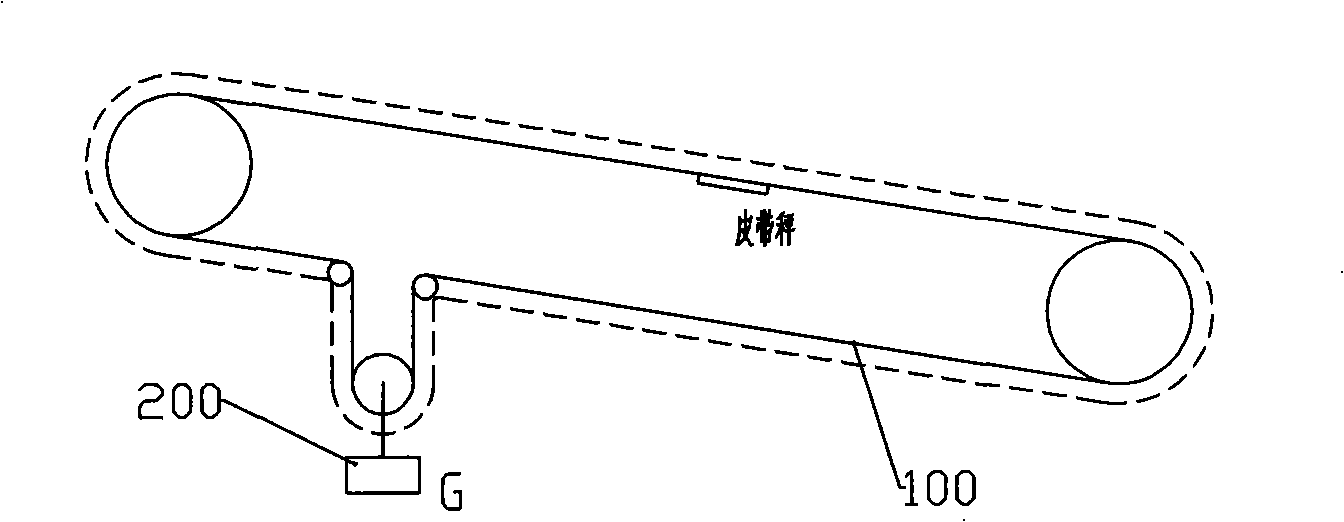

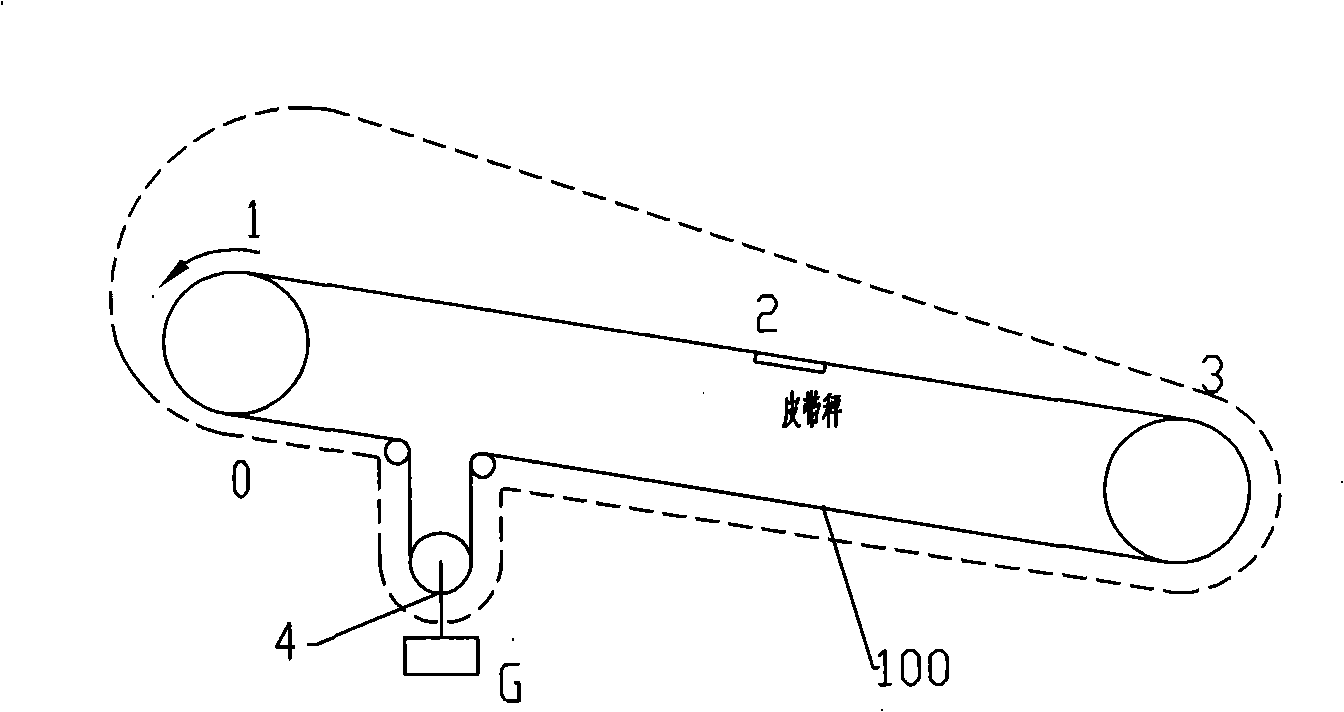

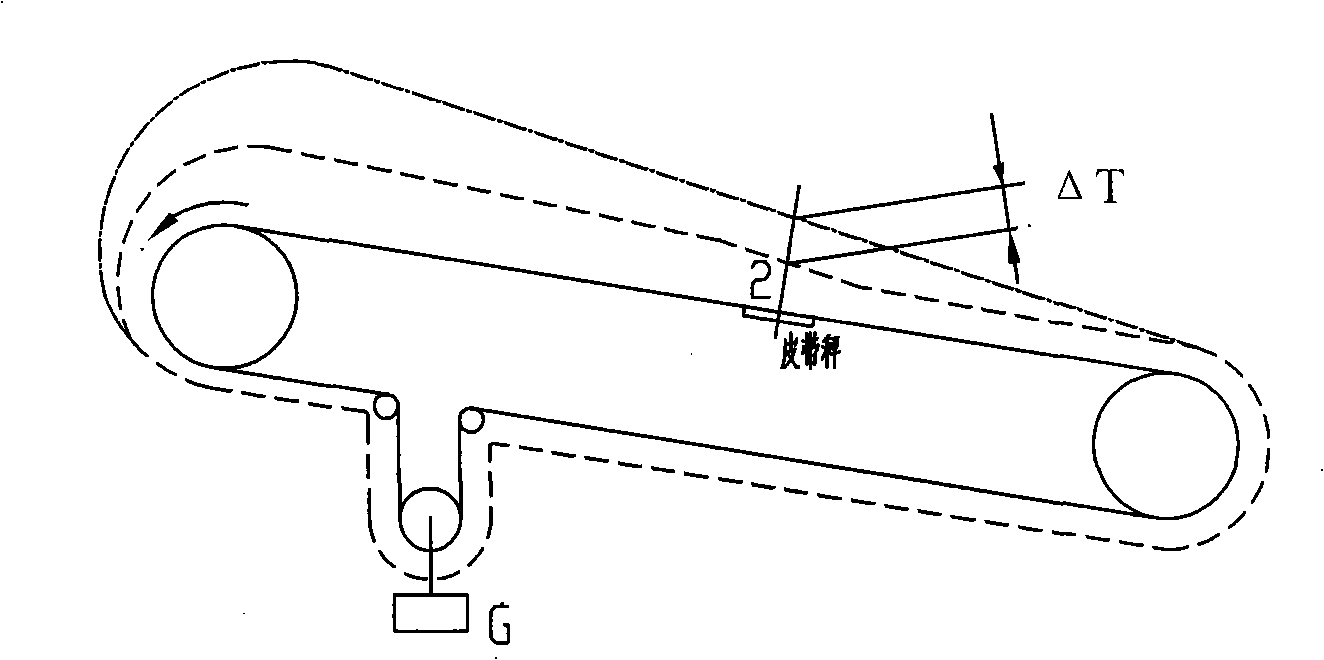

[0035] The principles and methods of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention.

[0036] 1. Some basic concepts about belt tension

[0037] 1.1 Belt tension conditions and hammer mass under normal operation of the belt conveyor

[0038] The tension of the belt varies over the entire length, and there are many influencing factors. In order to ensure the normal operation of the belt conveyor, the tension of the belt must meet two conditions:

[0039] 1.1.1 The belt conveyor must be able to work normally under the premise of a certain belt tension. Only when the belt tension reaches a certain level can sufficient friction be generated between the driving pulley and the belt (the circumferential force on all pulleys is transmitted to the belt through friction. on the belt) to keep the belt from slipping. To ensure that the belt conveyo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap