Asphalt weighing, proportioning and conveying system

A conveying system and asphalt material technology, applied in the field of asphalt mixture conveying equipment, can solve the problems of inaccurate asphalt weighing control, increase the workload of mixing station operators, and the finished material cannot meet the construction requirements, so as to improve work efficiency, The effect of ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

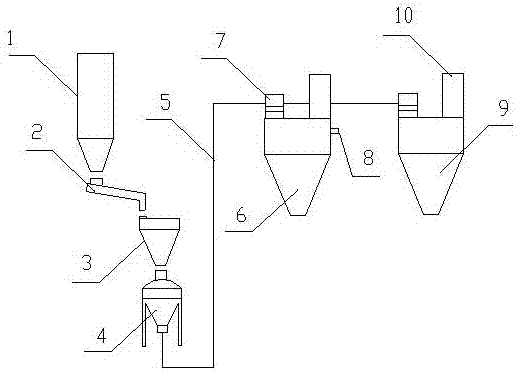

[0013] Such as figure 1 As shown, an asphalt weighing and batching conveying system in this embodiment includes a storage bin 1 for storing asphalt material, and a high-precision air-activated feeder 2 is arranged at the bottom outlet of the storage bin 1, which can To realize the flow control of the asphalt material, a weighing hopper 3 for weighing the asphalt material is set at the bottom outlet of the feeder 2, and the asphalt material weighed by the weighing hopper 3 enters and exits at the bottom of the weighing hopper 3 Connected air mixing pneumatic sending tank 4, the outlet of the pneumatic sending tank 4 is connected to the buffer bucket 6 through the delivery pipeline 5, a receiver switch 7 is arranged at the feed port of the buffer bucket 6, and at the same time, the buffer bucket 6 is provided with a material level controller 8 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap