Transmission shift device with variable gate blocking force

A technology of transmission and sub-transmission, which is applied in the direction of mechanical equipment, components with teeth, transmission control, etc., and can solve problems such as complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

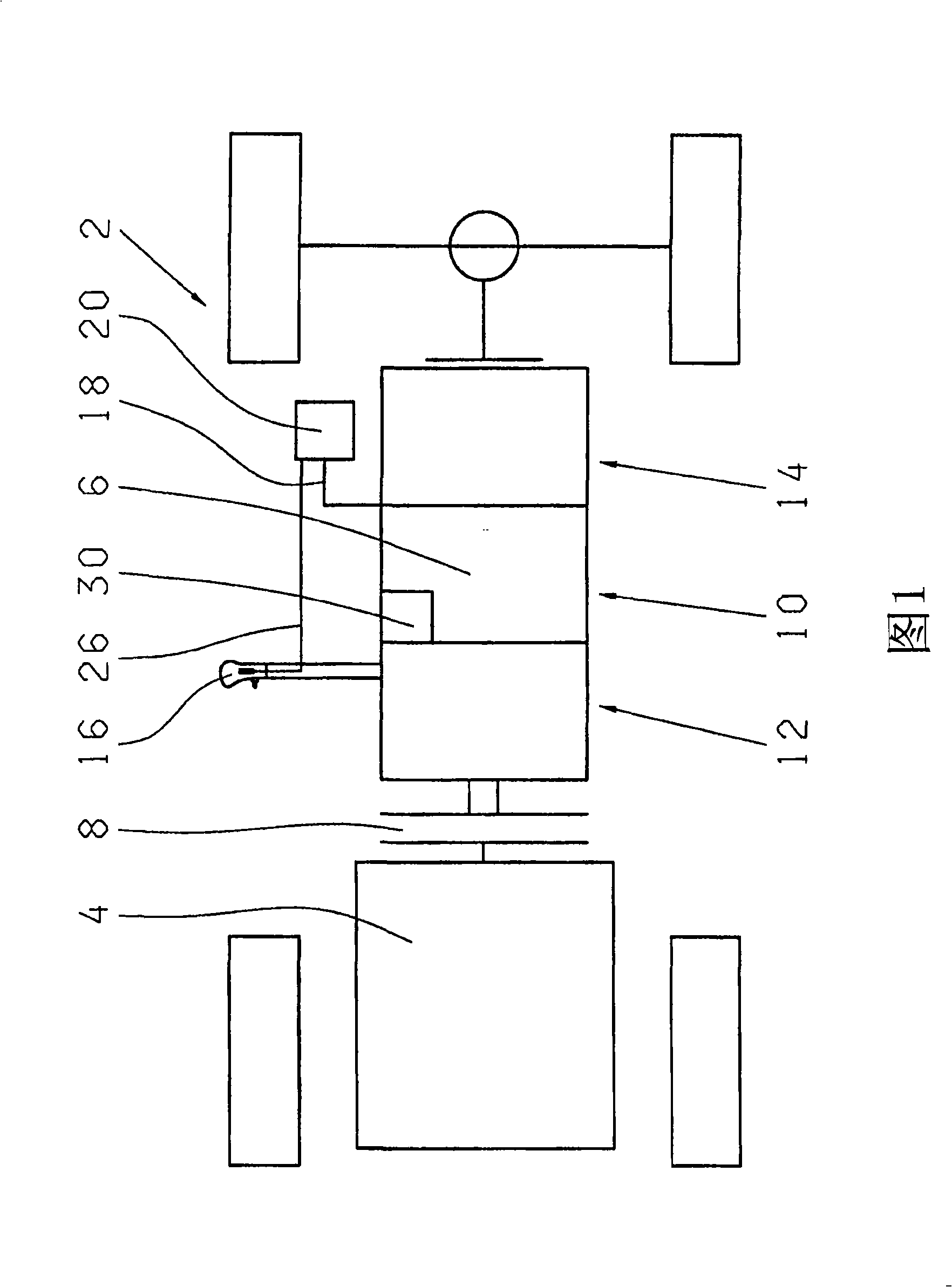

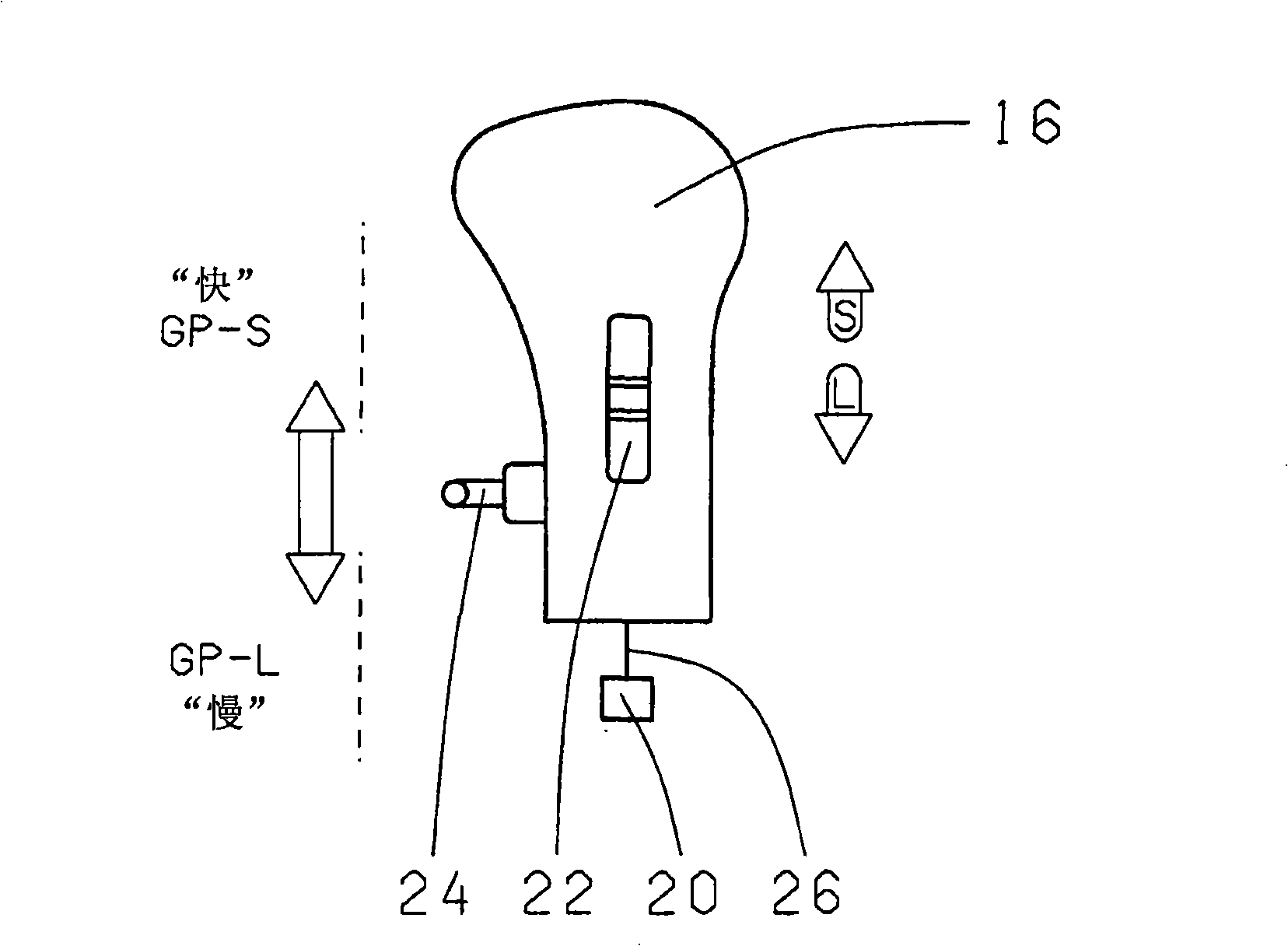

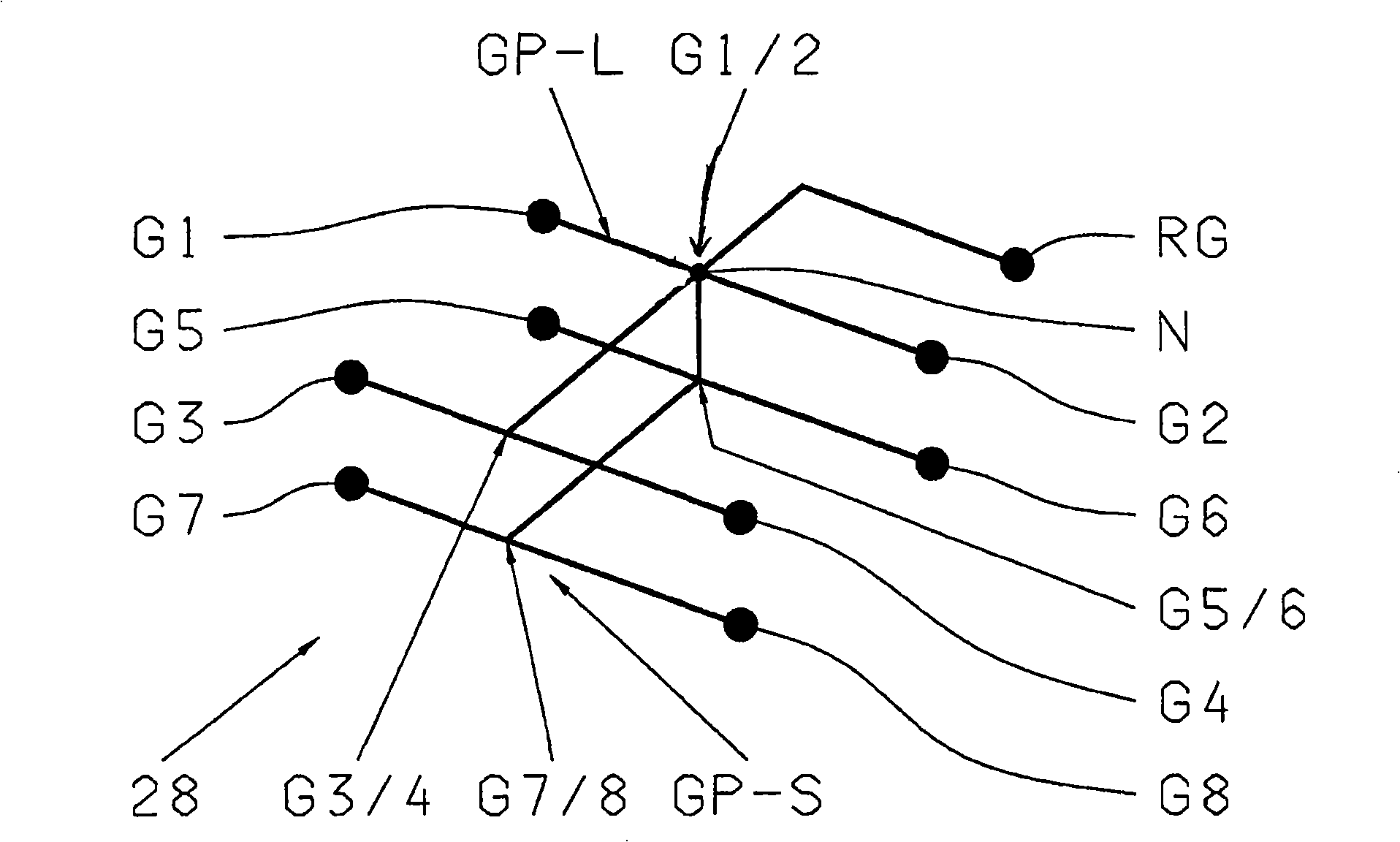

[0032]FIG. 1 thus shows a motor vehicle 2 comprising an engine 4 , a transmission 6 and a clutch 8 arranged between them. The transmission 6 has a main transmission 10 , a splitter 12 and a splitter 14 . The main transmission 10 is manually shifted by the driver of the vehicle via a selector lever 16 . To this end, the selector lever 16 is operatively connected via a shift and select shaft 32 and a transmission shifting device 30 to a transmission-side shifting element, not shown here. The transmission shifting device 30 also includes a blocking element, which prevents unintentional shifting operations and / or notifies the driver of this at least during a shifting operation on the selector lever side. The selector lever 16 can also be connected to a transmission shifting device 30 via a pneumatic line (not shown). The transmission 6 is generally connected via an electrical connection line 18 to the electronic control unit 20 and the selector lever is connected to the electron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com