Electric fork-lift truck and process for manufacturing the same

An electric forklift, forklift technology, applied in the direction of lifting device and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

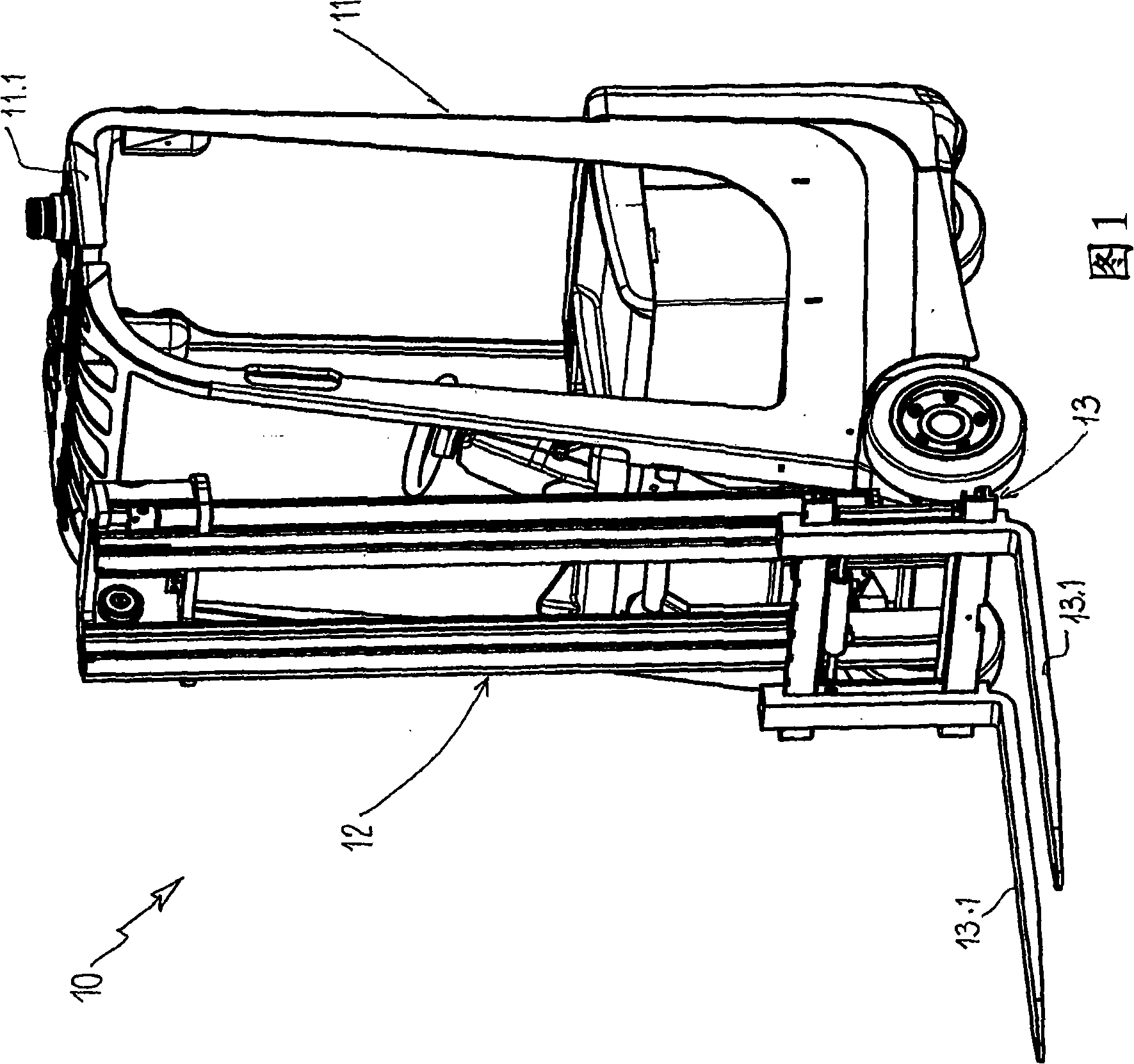

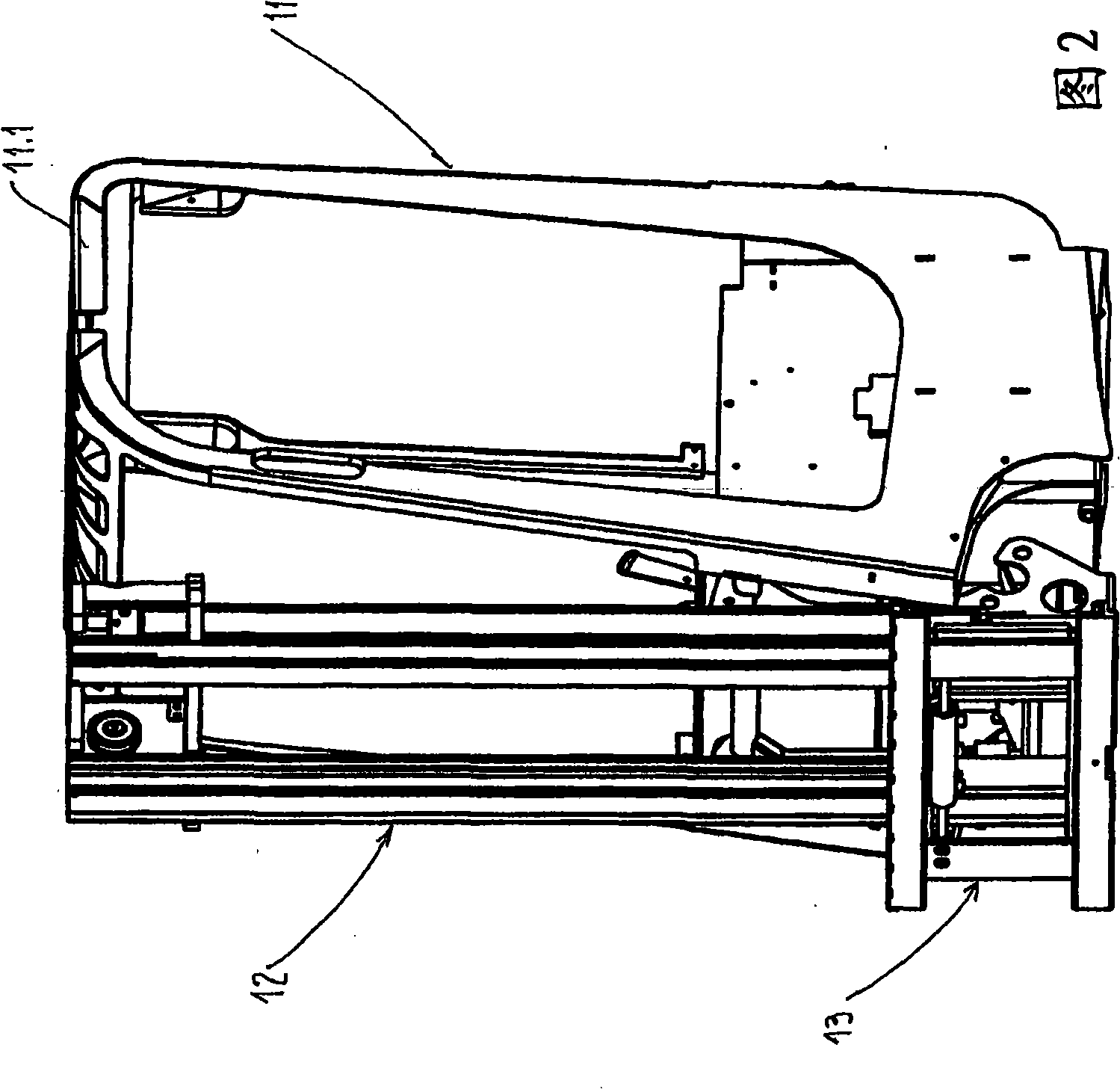

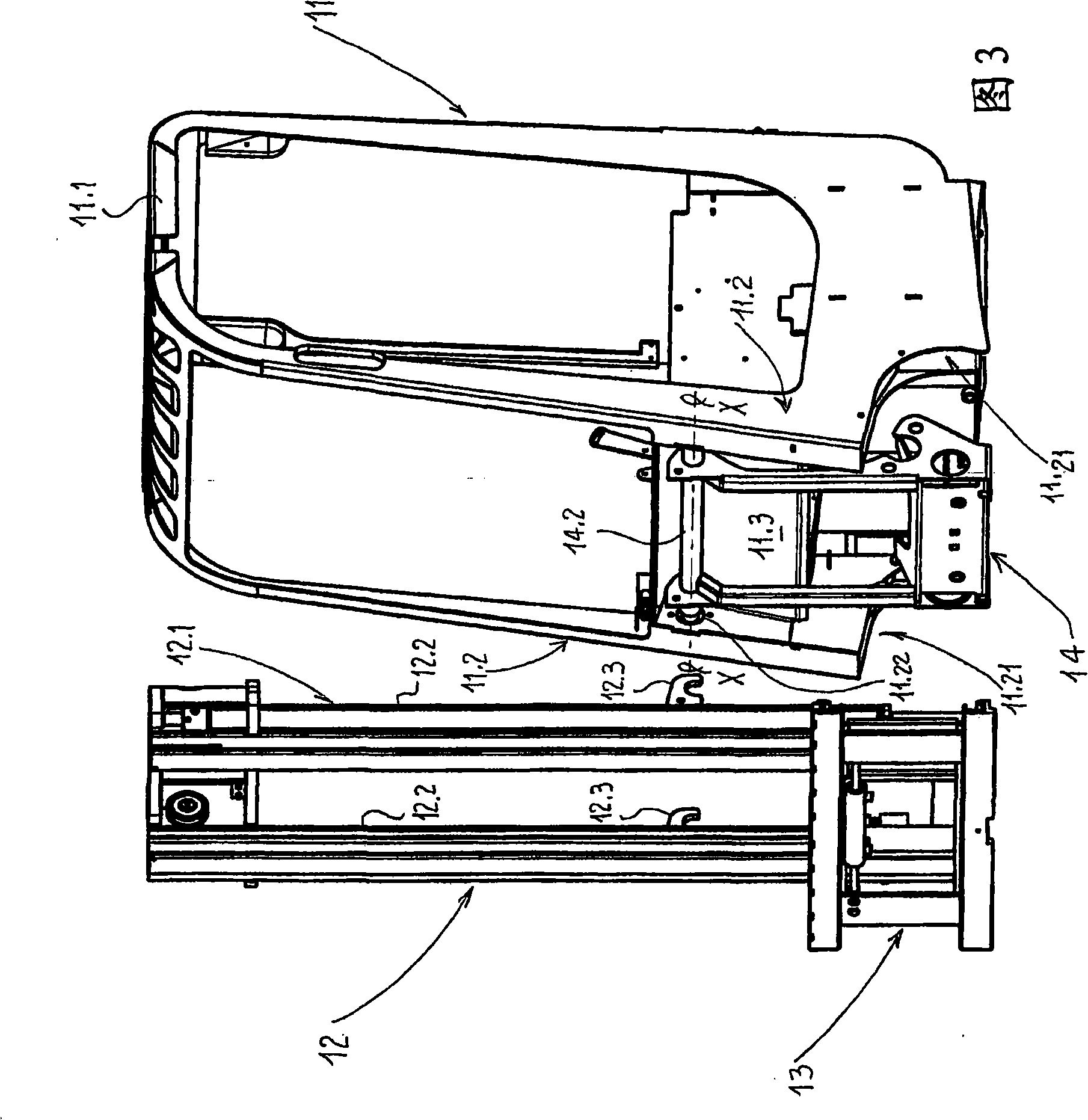

[0027] In the accompanying drawings, the three-wheeled electric forklift is marked as 10 as a whole (Fig. 1).

[0028] Such a forklift truck 10 includes a combined body 11 and a mast 12 (FIG. 3).

[0029] The combined body 11 is provided with a safety roof 11.1 and comprises an operator's compartment with associated controllers, hydraulic and electrical circuits and controls and a compartment containing batteries and ballasts, said compartments being known and no longer illustrate.

[0030] The lateral sides 11.2 of the body 11 have a box-like body on the front side by providing corresponding wheel housings 11.21 on the underside, and between the lateral sides 11.2 are accommodated front panels 11.3 which partly re-enter the body and A lower region of the passenger compartment is defined on the front side.

[0031] The gantry 12 comprises a rigid rectangular frame 12.1 provided with two mutually parallel vertical longitudinal members 12.2 extending in height and being slidab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com