Method for knitting tubular fabric having border pattern

A knitted fabric and tubular technology, which is applied to the weaving field of tubular knitted fabrics with fringe patterns, can solve problems such as small effects, and achieve the effects of simplifying weaving and suppressing the generation of height differences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Next, embodiments of the present invention will be described in detail below with reference to the drawings.

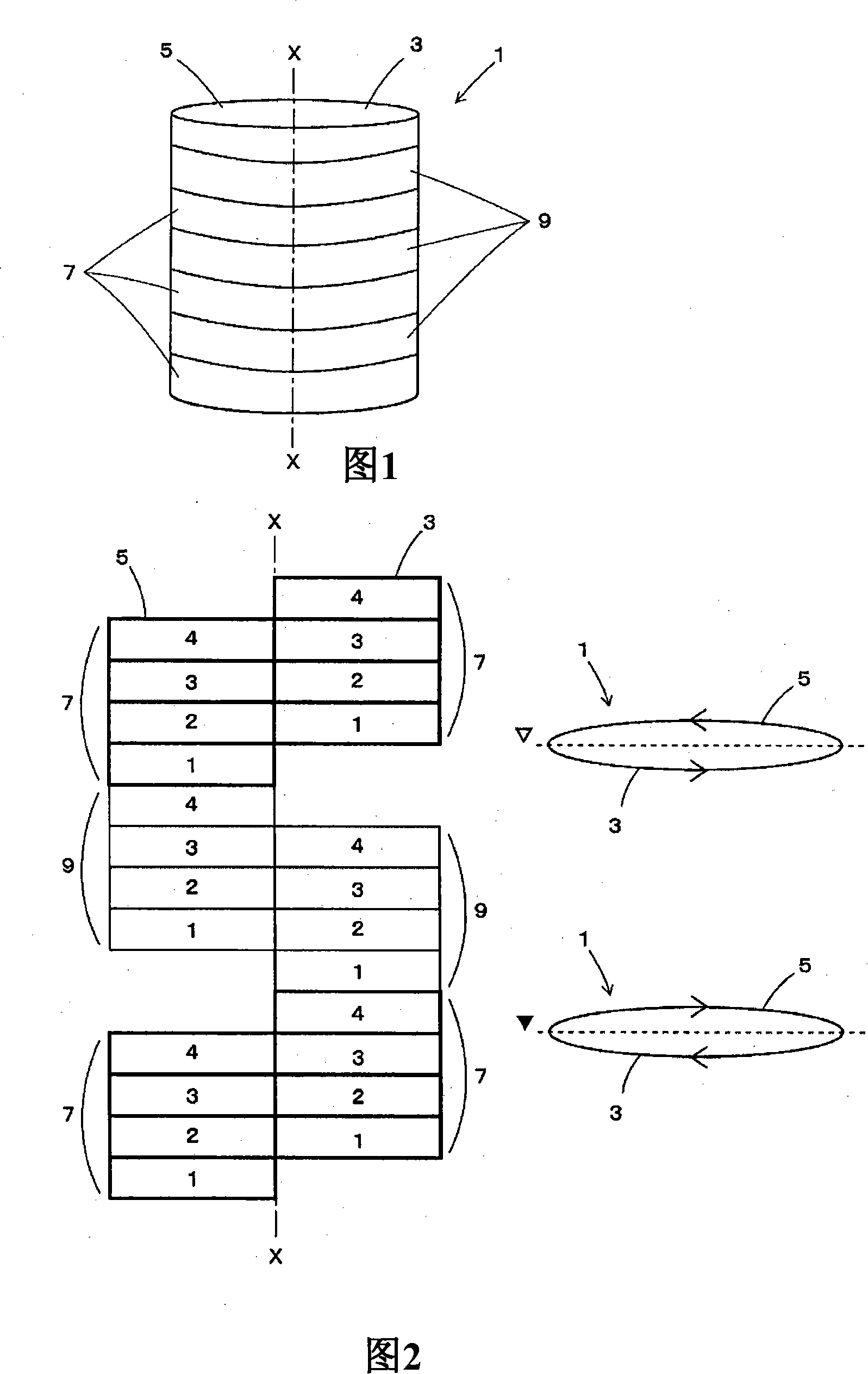

[0021] figure 1 A tubular knitted fabric 1 having two-color fringe patterns of A color and B color is shown. In the flat knitting machine, although not shown, a yarn exchanging device such as a splicer and a knotter is provided between the yarn bobbins for A color and B color and the YF that reciprocates on the needle bed to feed yarn to the knitting needles. The controller of the flat knitting machine can switch the knitting yarn by operating the yarn changing device at a required timing based on the knitting data. As such a flat knitting machine, for example, a flat knitting machine described in Japanese Patent No. 2816784 (corresponding patents are US Patent No. 536966 and European Patent No. 0574881) can be used.

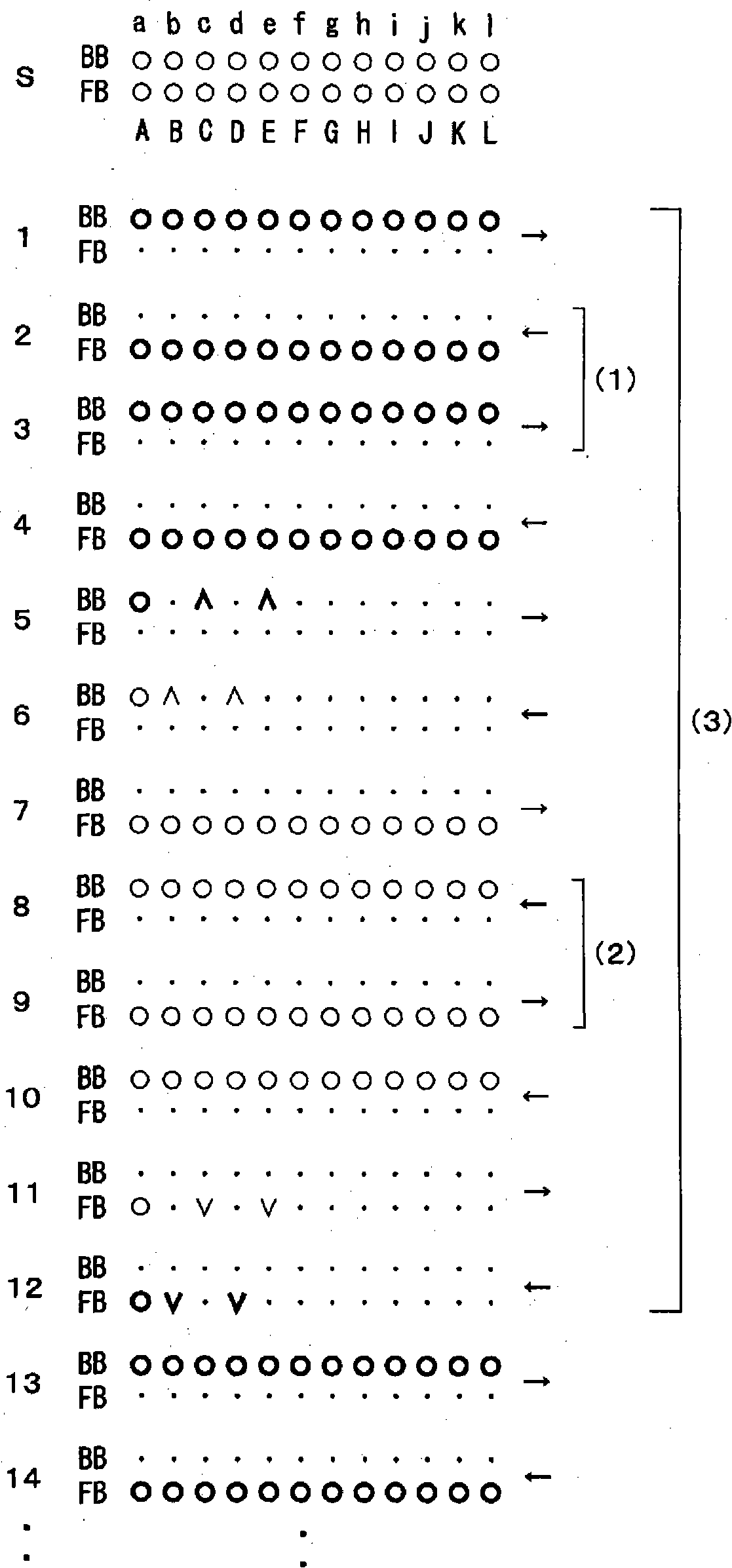

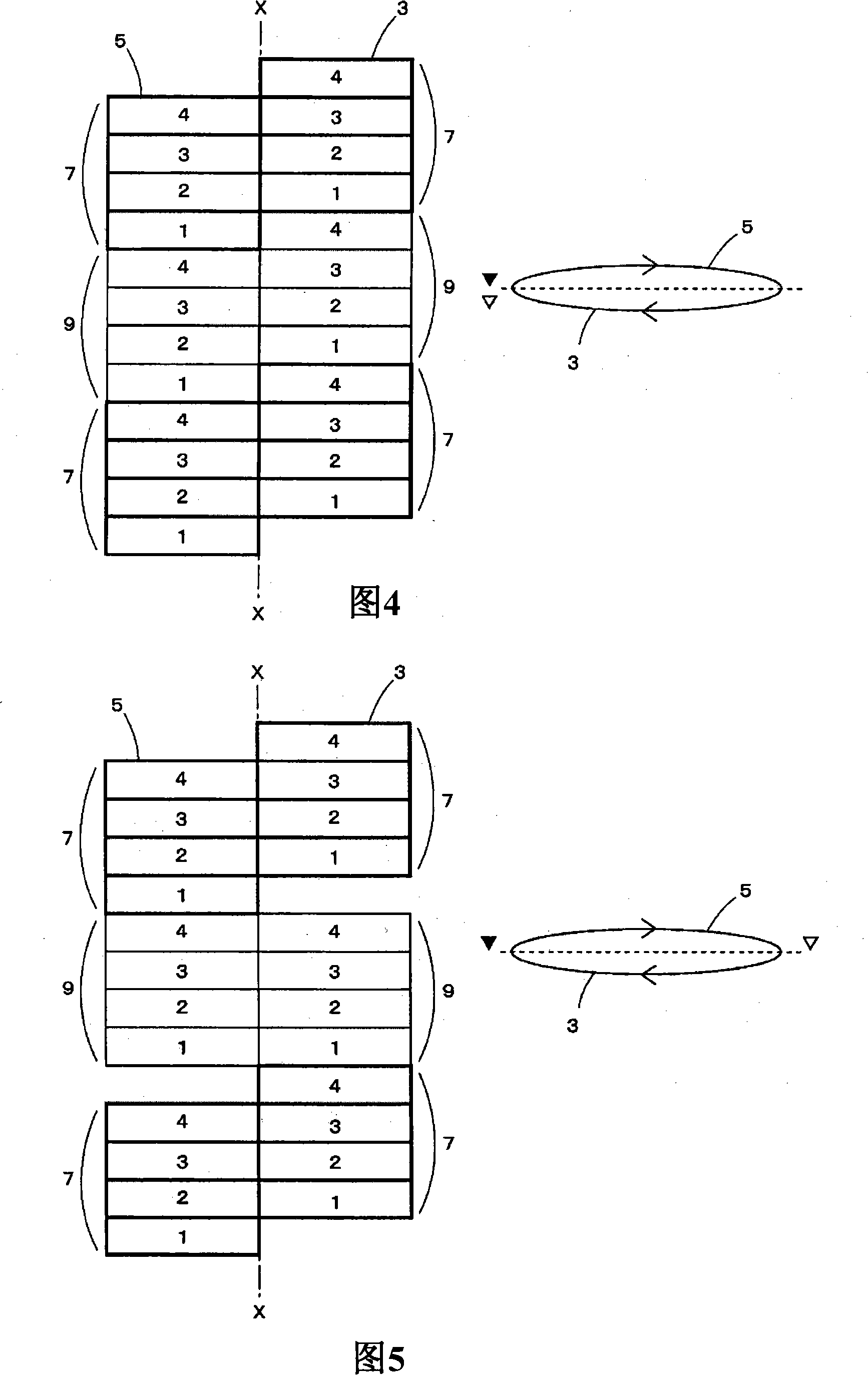

[0022] figure 2 express with the above Figure 5 , the diagram of the weaving of the present embodiment corresponding to Fig. 6 . Among t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com