Direct-injection acid dye digital printing ink and application thereof

A technology of acid dyes and digital printing, applied in application, ink, dyeing, etc., to achieve the effect of inhibiting ink seepage, optimizing wastewater treatment, and improving printing clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Take 20 copies of acidic dyes, 0.5 dispersants, 20 parts of polyol moisturizing solvent, 0.6 pH buffer solution, 10 temperature sensitive gel materials, 1.2 parts of the wetting agent, 0.5 cases of preservative, 0.8 parts of surfactant and 0.8 parts of deionized water 46.4 copies.

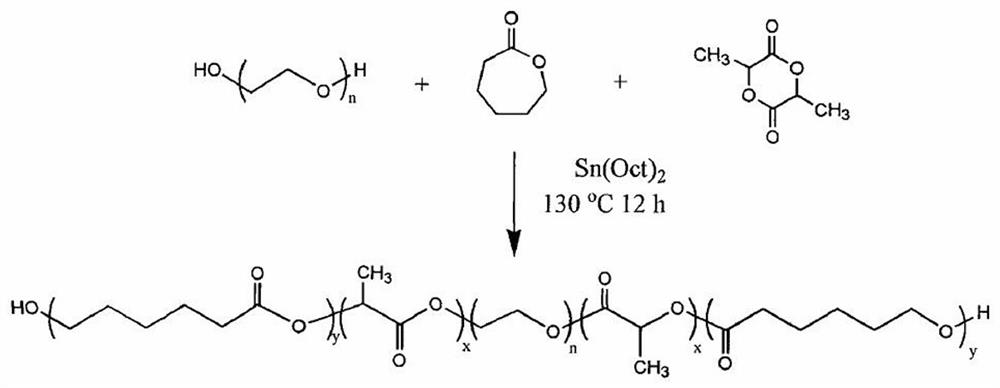

[0030]In this example, according to the technical solution disclosed in the preparation of temperature-sensitive hydrogel and preparation method based on chemical crosslinked gel particles, the preparation of temperature-sensitive hydrogels, and polyethylene glycol is preparative. One of the agent, hexide, lactide, and algegin, or their copolymers are raw materials, tin tin as a catalyst, and the polymerization reaction obtains a block copolymer; the polyethylene glycol is a monohydroxy group Polyethylene glycol, bishydroxy polyethylene glycol or multi-arm polyallow, polyethylene glycol has a molecular weight of 500 to 5,000, preferably molecular weights 1000 to 2000, particularly preferably bet...

Embodiment 2

[0046] The temperature-sensitive gel material was prepared according to the method provided in Example 1. Other raw materials are the same as in Example 1.

[0047] Take 20 parts of acidic dye, 0.5 parts of the dispersant composition, 20 parts of the polyol moisturizing solvent, 0.6 pH buffer solution, 20 parts of the temperature sensitive gel material, 1.2 parts of the wetting agent, 0.5 cases of preservative, 0.8 surfactants and 0.8 parts of the surfactant 36.4 parts of ion water; put deionized water, acidic dyes, temperature-sensitive gel materials, etc. in sequence, stirred in the container, high speed at a speed of 75 minutes at a speed of 700 rpm, and filtered the stirred material, first using a pore diameter of 0.8 um filter, After filtration of 0.45 um filter, the filtrate was filtered with a pore diameter of 0.22 um filtration, and the finished ink was obtained as a 4% sample.

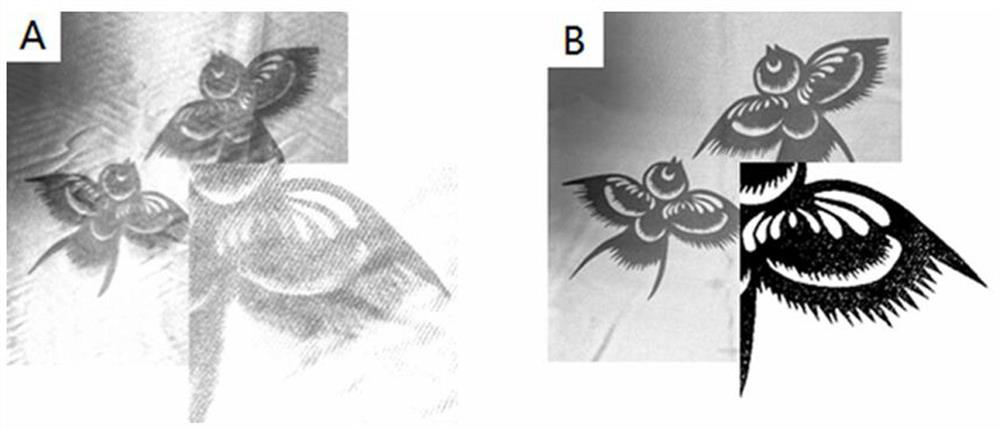

[0048] Heat the nylon fabric to 63 degrees Celsius, the ink is heated to 30 degrees Celsius, a...

Embodiment 3

[0050] The temperature-sensitive gel material was prepared according to the method provided in Example 1. Other raw materials are the same as in Example 1.

[0051] Take 20 parts of acidic dye, 0.5 parts of the dispersant composition, 20 parts of the polyol moisturizing solvent, 0.6 pH buffer solution, 30 temperature sensitive gel materials, 1.2 wetting agent, 0.5 cases of preservative, 0.8 parts of surfactant 26.4 parts of ion water; deposit water, acidic dyes, temperature-sensitive gel materials, etc. in sequence, stirred in a container, at a high speed of 75 minutes, filtered after stirring, and then filtered with a pore size of 0.8 um filter, first. The filtration was filtered again, and finally filtered with a pore diameter of 0.22 um filtration, and the finished ink was obtained as a 6% sample.

[0052] Heat nylon fabrics to 60 degrees Celsius, the ink is heated to 30 degrees Celsius, and printing using a Plante digital printing machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com