A case and a manufacturing method for the same

A manufacturing method and shell technology, which are applied in the directions of closed cabinets, cabinets/cabinets/drawer parts, electrical equipment shells/cabinets/drawers, etc., can solve the problems of labor, time, cost, etc., and reduce The effect of labor and time, suppression of height difference, and maintenance of beauty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In addition, the drawings do not show actual dimensions, and specific dimensions and the like should be judged in light of the following description. In addition, it is a matter of course that the relationship and the ratio of the mutual dimension are different among drawings.

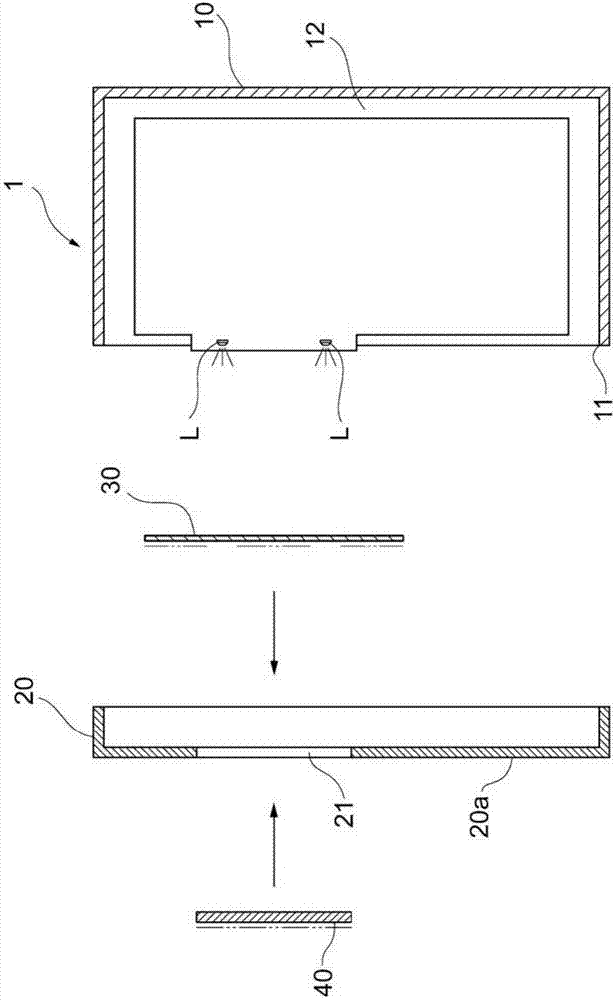

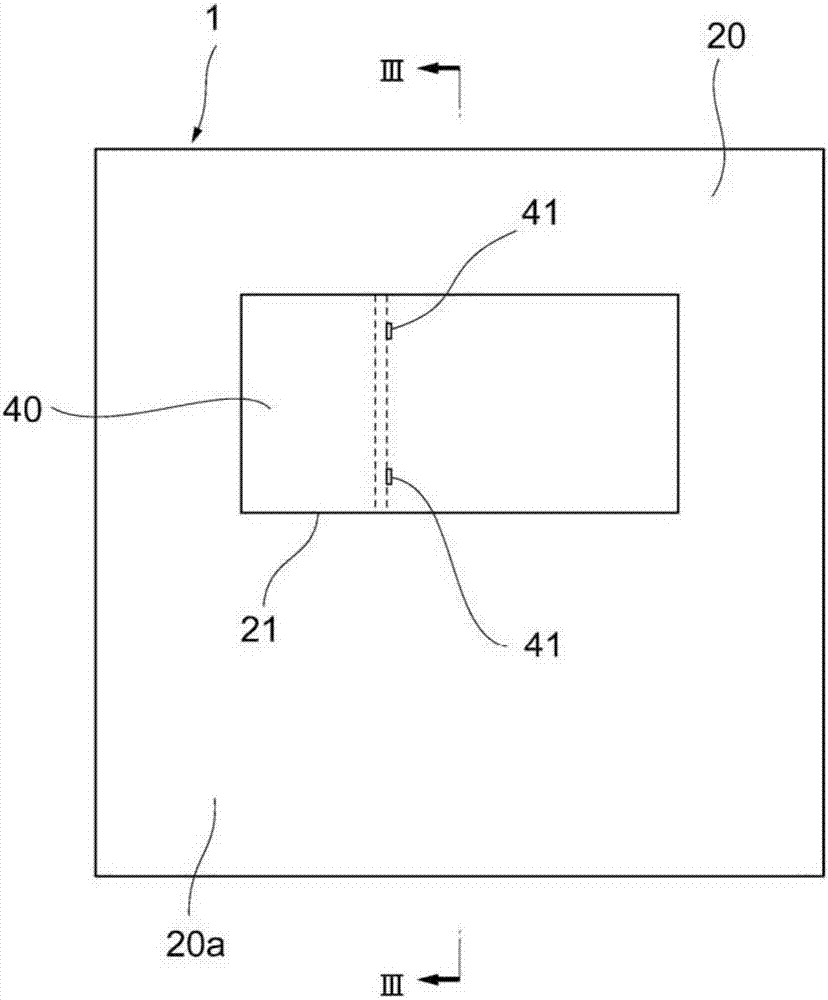

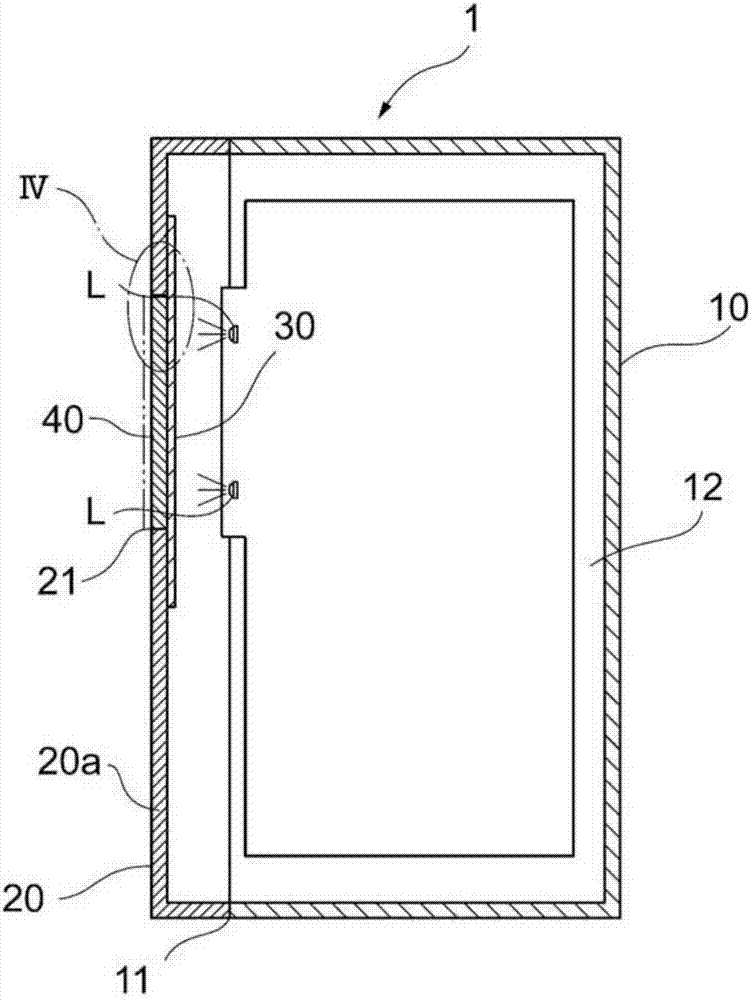

[0032] First, use Figure 1 to Figure 5 The structure of the casing 1 according to the embodiment of the present invention will be described. The casing 1 involved in this embodiment is as Figure 1 ~ Figure 3 Shown is in the shape of a cuboid, with each surface composed of flat metal plates. The housing 1 includes: a main body 10 having an opening 11 ; and a cover 20 attached to the opening 11 of the main body 10 .

[0033] Such as figure 1 and image 3 As shown, a storage space 12 for storing various items (for example, electronic components including light emitting components L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com