Reduction of tonal noise in cooling fans using splitter blades

A technology of splitter blades and fans, which is applied to parts of pumping devices for elastic fluids, liquid fuel engines, machines/engines, etc., can solve the problems of low frequency component amplitude and less obvious comparison, and achieve discrete noise Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

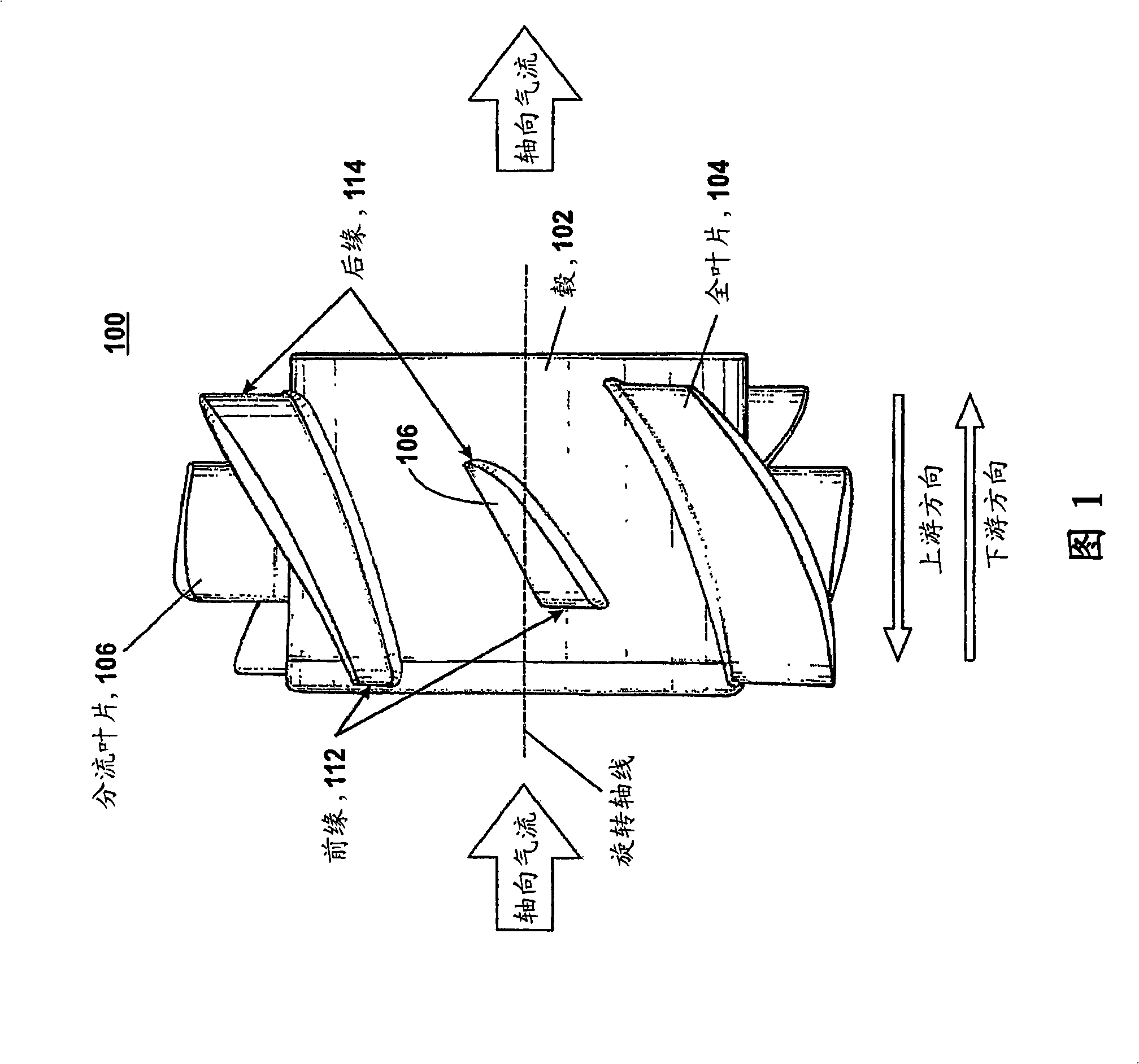

[0014] Figure 1 shows an axial flow impeller 100 made in accordance with the teachings of the present invention. Figure 1A is a photo of the impeller prototype shown in Figure 1. The impeller includes a hub 102 . A plurality of fan blades 104 , 106 are arranged around hub 102 . This figure shows what is commonly referred to as a "full blade" 104 . Disposed between a pair of full blades 104 is a blade called a "splitter blade" 106 . The blades 104, 106 are connected to the hub 102 at the roots of the blades. As the impeller 100 rotates about its axis of rotation, an axial flow is created, as indicated by the arrows. According to the invention, the splitter blades 106 in FIG. 1 are connected to the hub 102 so that their axial position relative to the full blades falls between the leading edge 112 and the trailing edge 114 of these full blades 104 . This will be in figure 2 discussed in detail.

[0015] Referring now to Figure 5, a detailed description of a cross-sectiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com