Method for producing optical element

A technology for optical components and manufacturing methods, applied to optical components, other household appliances, household appliances, etc., can solve the problem of low degree of freedom of lens forming, achieve the effect of preventing ghosting or flare, and improving the degree of freedom of forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

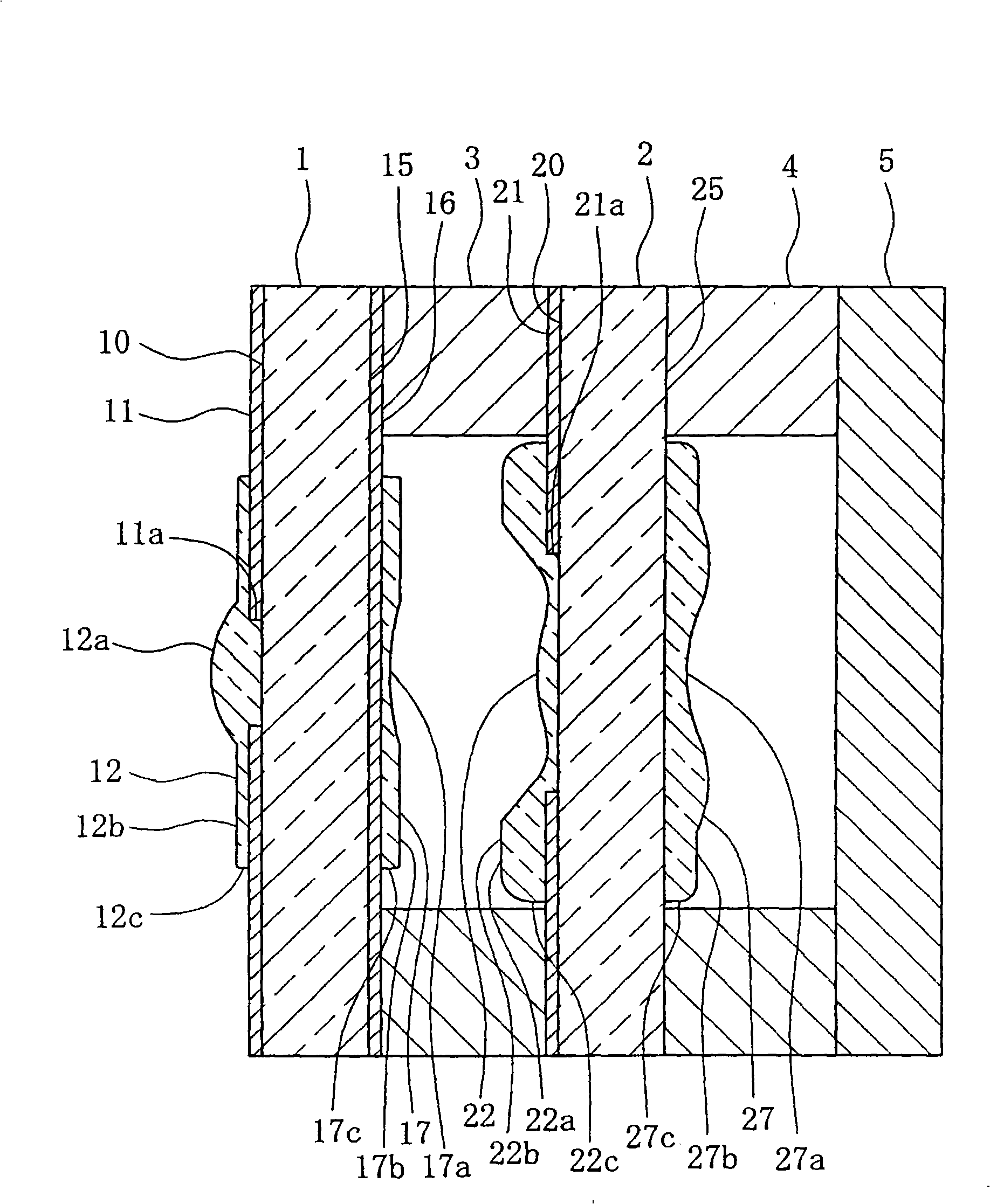

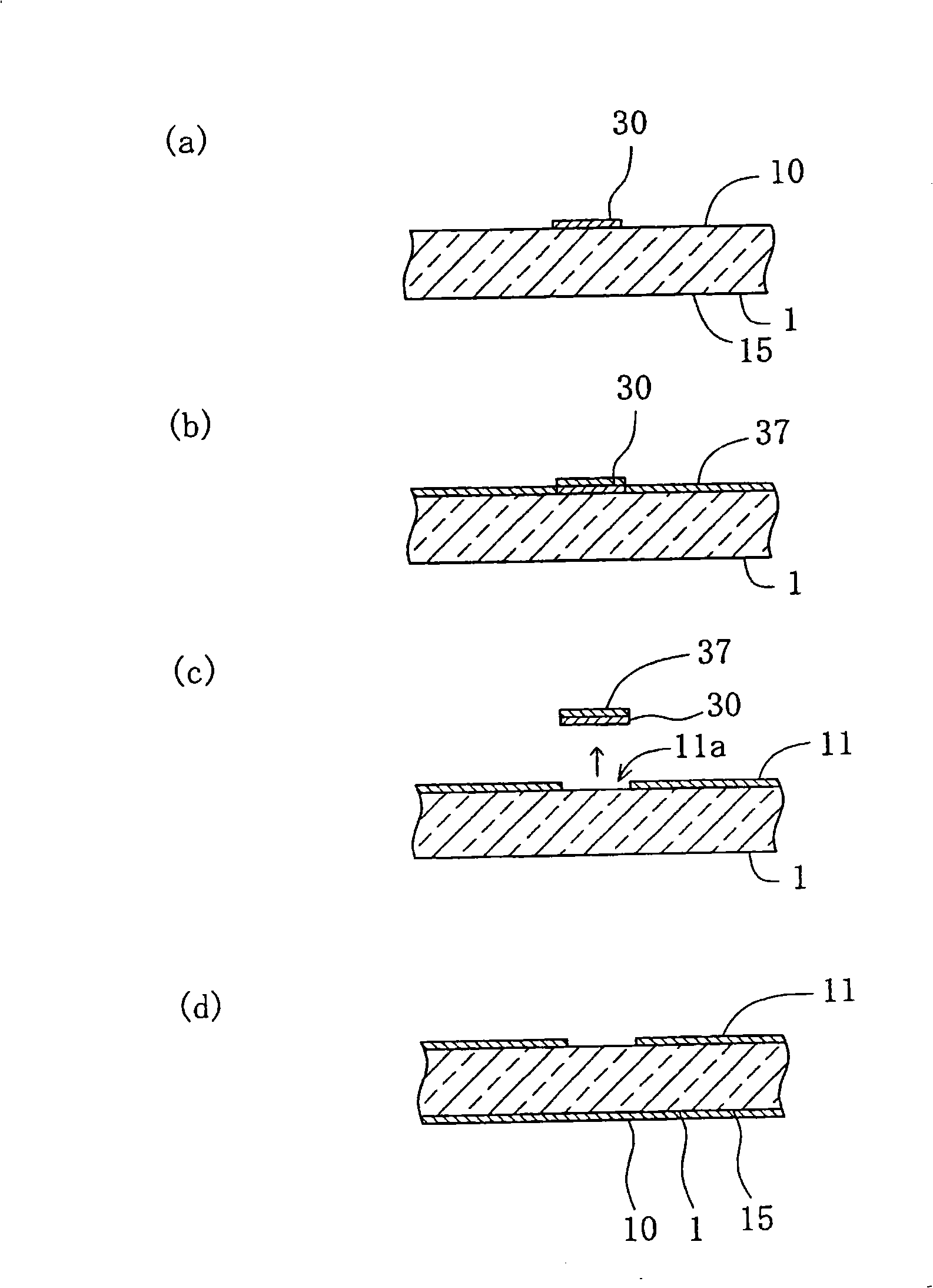

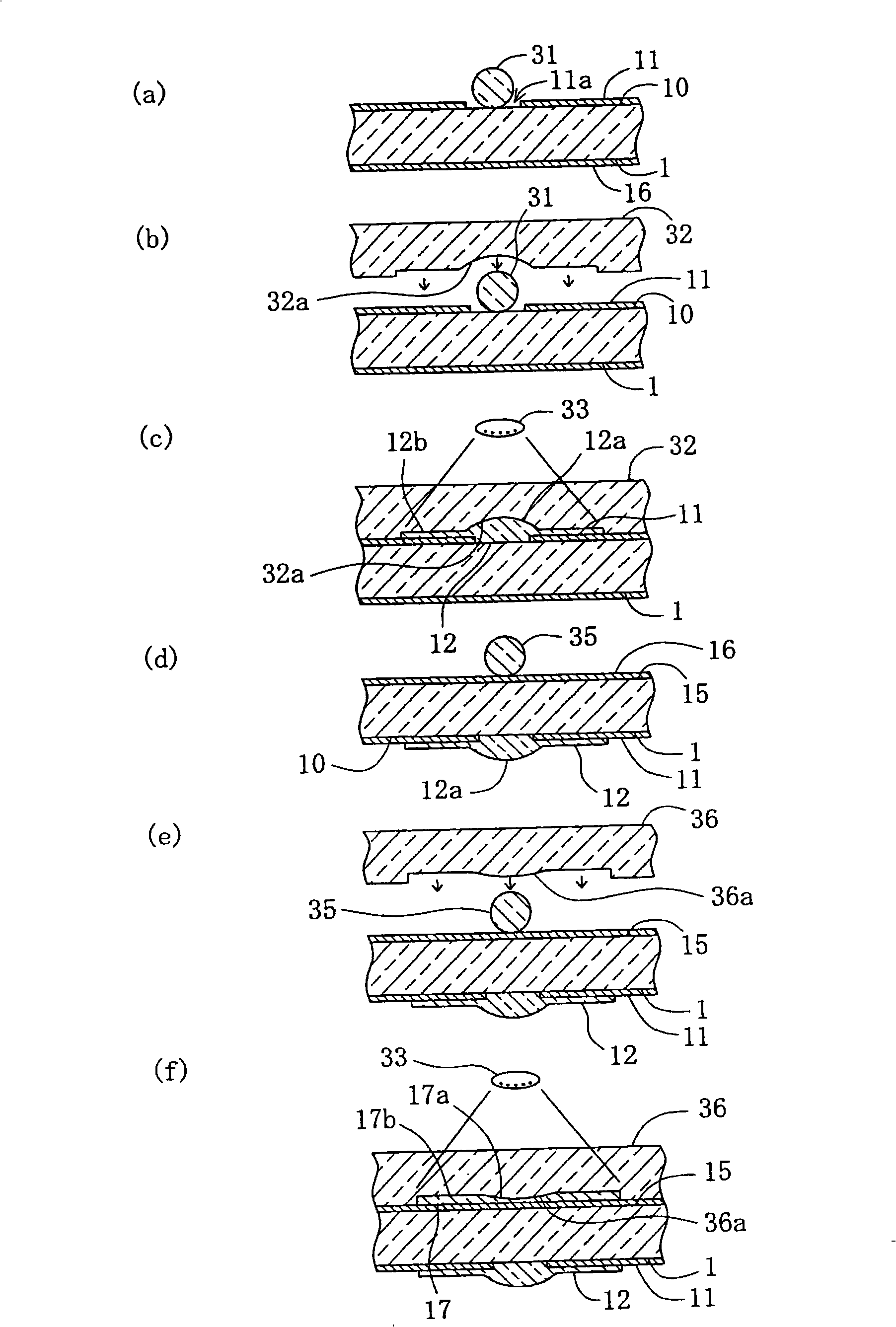

[0025] Embodiments of the present invention will be described in detail below using the drawings. figure 1 In , a cross-sectional view of the optical element of this embodiment is shown. As shown in the figure, in the optical element of the present embodiment, the first transparent substrate 1 and the second transparent substrate 2, which are made of transparent glass and have a lens portion on the surface, face each other through the first spacer 3, and the second The transparent substrate 2 faces the light receiving unit 5 with the second spacer 4 interposed therebetween. As a result, light rays incident from the first transparent substrate 1 side pass through the lens portions respectively formed on the surfaces of the first transparent substrate 1 and the second transparent substrate 2 , and converge on the light receiving portion 5 .

[0026] On the surface of the first surface 10 of the first transparent substrate 1, the first light-shielding film 11 is adhered. The op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com