Apparatus for substrate appearance inspection

A technology for visual inspection devices and substrates, used in measuring devices, optical testing flaws/defects, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0046] Hereinafter, a substrate appearance inspection device according to a first embodiment of the present invention will be described with reference to the drawings.

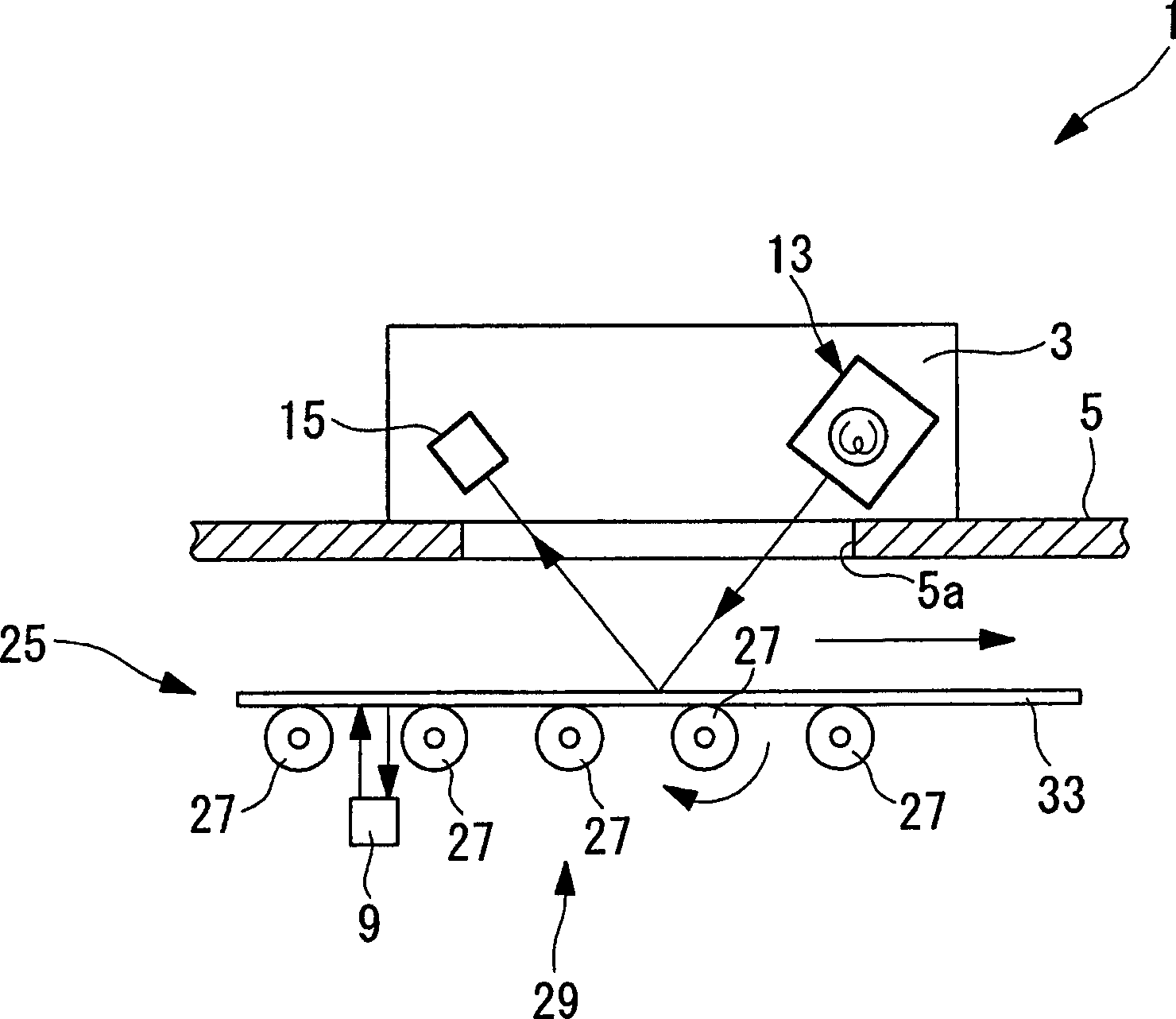

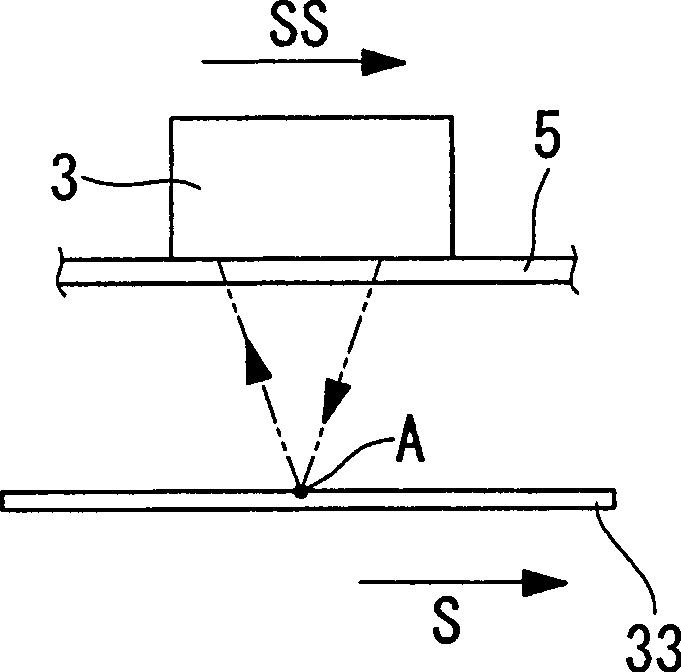

[0047] The substrate visual inspection device 1 of the present embodiment is used to inspect, for example, Image 6 The shown substrate conveying path (substrate conveying unit) 25 having a conveyor 23 composed of a plurality of rollers 21, or on Figure 7 The entire surface of the mother glass substrate (substrate to be inspected. Hereinafter referred to as "substrate") 33 for manufacturing FPD conveyed on the substrate conveyance path 31 provided with the floating plate 29 having a plurality of ejection holes 27 is imaged. A device for microscopic inspection.

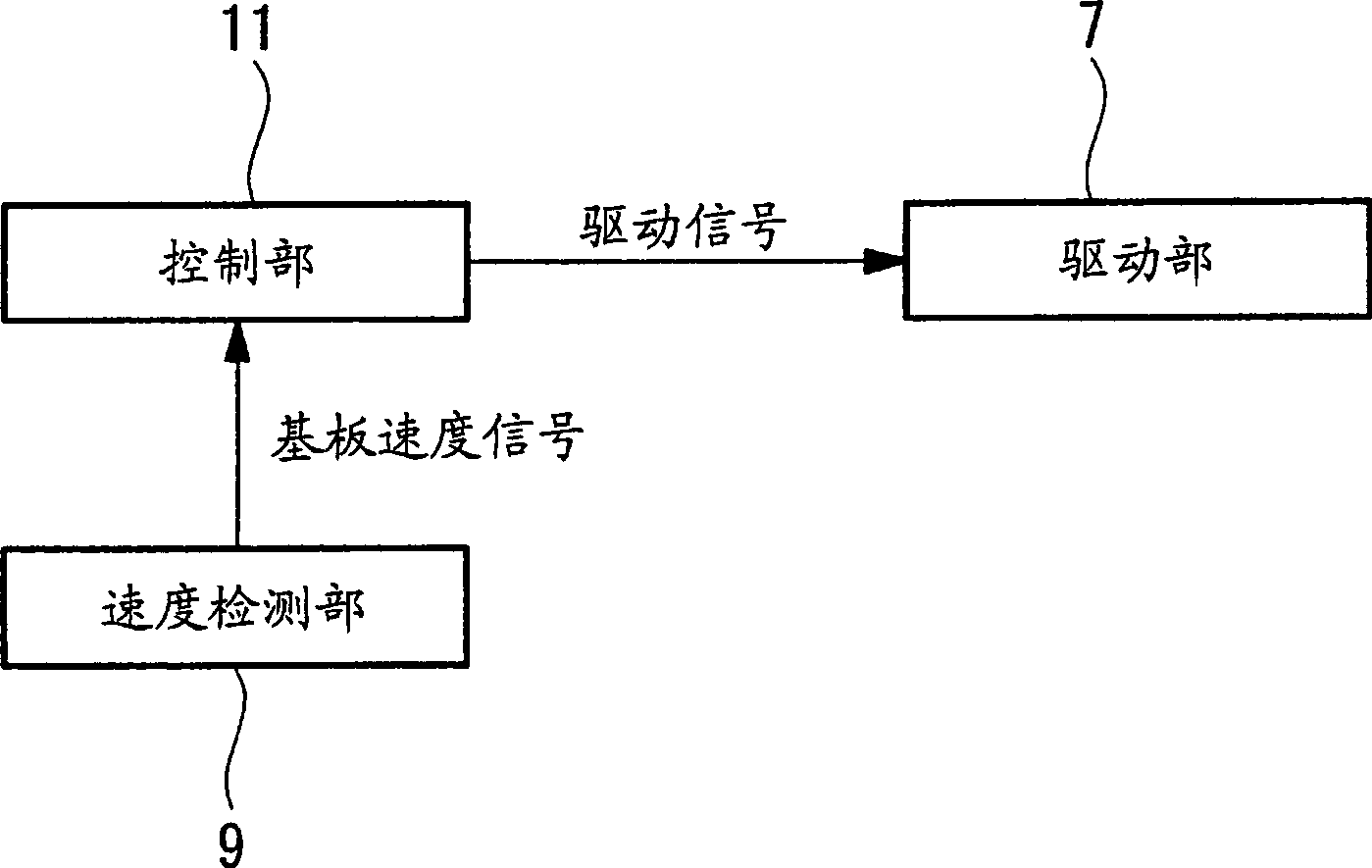

[0048] Such as figure 1 with figure 2 As shown, the substrate visual inspection apparatus 1 has: a substrate conveyance path 25 connecting manufacturing devices for manufacturing a substrate 33; The appearance of the surface of the substrate 33 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com