Single layer papermakers fabric

A technology for paper machines and fabrics, which is applied in the field of air-drying and paper or tulle fabric formation, and can solve problems such as deformation and wrinkles without mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

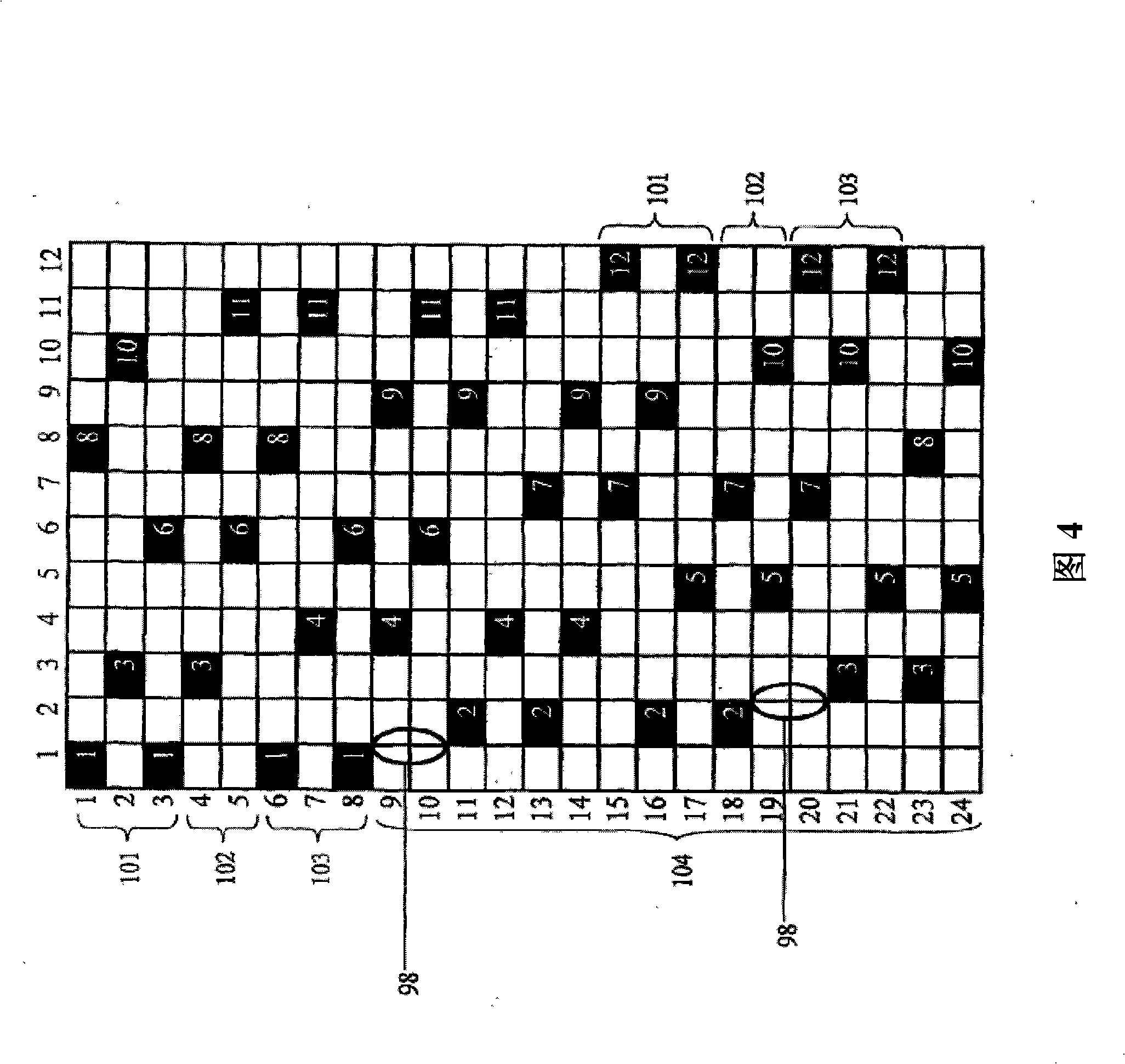

[0048] Referring to FIG. 6 , there is shown a third embodiment of the present invention comprising an N×2N pattern, where N is ten. The ten warp yarns 100 are numbered across the top of the figure as yarns la through 5b, and the weft yarns 200 are numbered down the left side of the figure as yarns 1 through 20. However, the ten warp yarns 100 comprise five pairs, the two members of each pair labeled "a" and "b" yarns, following the same path with no offset from each other. For example, for warp yarns 1a and 1b, first portion 101 includes interweaving with weft yarns 1 and 3, second portion 102 floats above six weft yarns 200 (i.e., weft yarns 4 to 9) on the paper side, and third portion 103 includes interlacing with weft yarn 12. and 12, the second portion 102 floats on the paper side over the eight weft yarns 200 (ie, weft yarns 13 to 20). It can also be seen that between each "b" yarn of each pair and adjacent to the "a" yarn of the next pair, the first and second offset re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com